Series 6a operation & maintenance – technical data, 6a o & m : 35 – Bray 6A Series O&M Manual User Manual

Page 35

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Series 6A Operation & Maintenance – Technical Data

6A O & M : 35

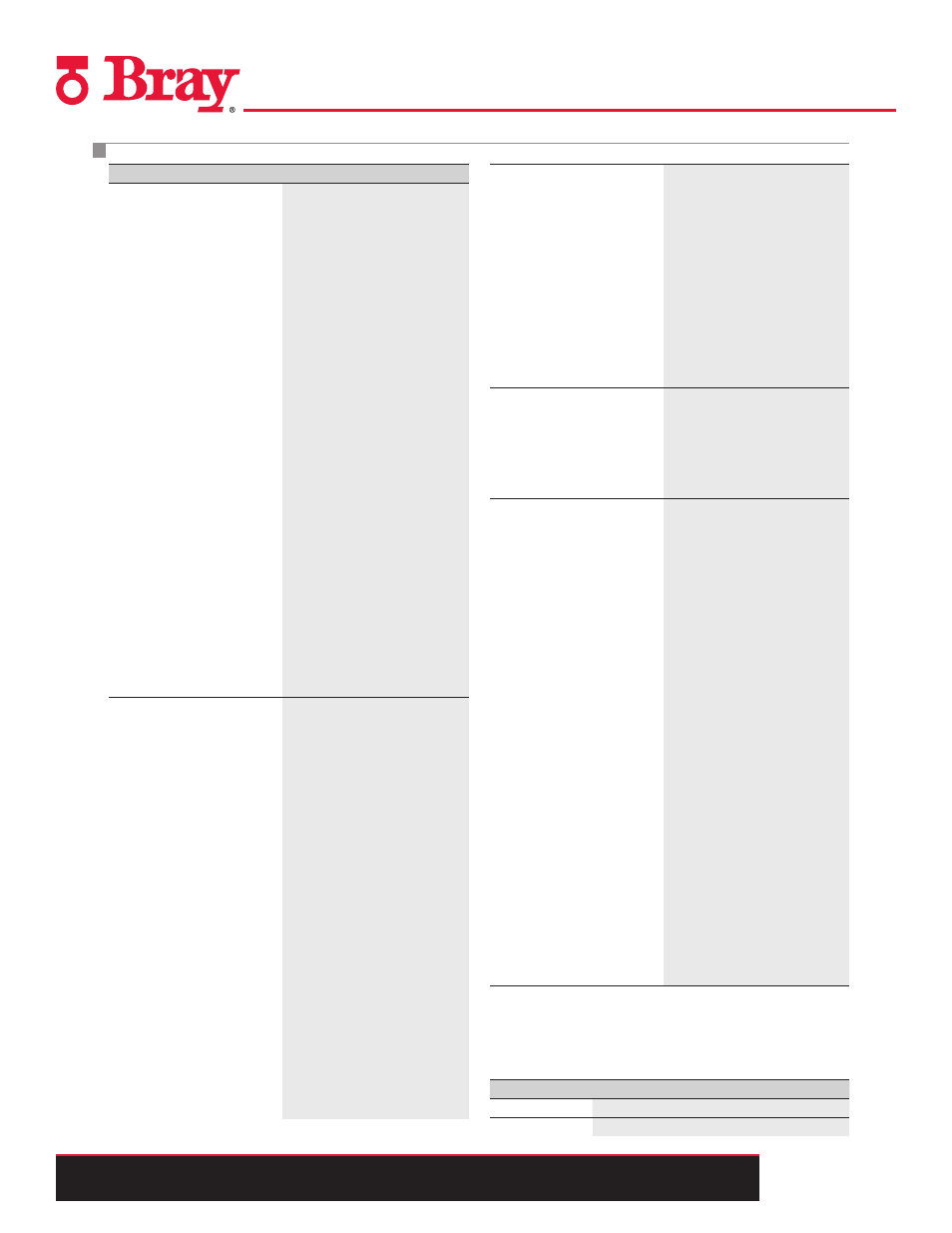

Technical specifications

1)

During commissioning at ≤ 0 °C (≤ 32 °F) make sure that the valves are

flushed long enough with the dry medium.

2)

At ≤ -10 °C (≤ 14 °F) the display refresh rate of the indicator is limited. Only

T4 is permissible when using I

y

module.

3)

-20 ... +80 °C (-4 ... + 176 °F) for 6DR55..-0G..., 6DR56..-0G...,

6DR55..-0D... and 6DR56..-0D...

4)

With the Ex d version (6DR5..5-...) the values are reduced by approx. 20 %

SIPART PS2 (all versions)

General data

Range of stroke (linear actuators) 3 ... 130 mm (0.12 ... 5.12 inch)

(angle of positioner shaft 16 ... 90°)

Angle of rotation (part-turn actuators) 30 ... 100°

Assembly

• On linear actuators

Using mounting kit 6DR4004-8V and

where necessary with an additional

lever arm 6DR4004-8L on actuators

according to IEC 534-6 (NAMUR)

with ribs, bars or flat face

• On part-turn actuators

Using mounting kit 6DR4004-8D

on actuators with mounting plane

according to VDI/VDE 3845 and

DIN 3337: The required mounting

console has to be provided on the

actuator side; shaft with groove and

female thread M6

Controller unit

• Five-point switch

Self-adjusting

• Deadband

- dEbA = Auto

Self-adjusting or can be set as fixed

value

- dEbA = 0.1 ... 10 %

Self-adjusting or can be set as fixed

value

A/D converter

• Scan time

10 ms

• Resolution

≤ 0.05 %

• Transmission error

≤ 0.2 %

• Temperature influence effect

≤ 0.1 %/10 K (≤ 0.1 %/18 °F)

Cycle time

• 20 mA/HART device

20 ms

• PA device

60 ms

• FF device

60 ms (min. loop time)

Binary input BE1 (terminals 9/10;

electrically conn. to basic device)

Suitable only for floating contact;

max. contact load < 5 µA with 3 V

Degree of protection

IP66 to EN 60 529/NEMA 4X

EMC requirements

EN 61326/A1 Appendix A.1 and

NAMUR NE21 August 98

Material

• Enclosure

- 6DR5..0-... (plastic)

Glass-fiber-reinforced Macrolon

- 6DR5..1-... (aluminum)

GD AISi12

- 6DR5..2-... (stainless steel)

Austenitic stainl. steel mat. No. 1.4581

- 6DR5..5-... (alum., press.-proof) GK AISi12

• Pressure gauge block

Aluminium AIMgSi, anodized

Vibration resistance

• Harmonic oscillations

(sine-wave) according to

EN 60068-2-6/05.96

3.5 mm (0.14 inch),

2 ... 27 Hz 3 cycles/axis

98.1 m/s² (321.84 ft/s²),

27 ... 300 Hz, 3 cycles/axis

• Bumping (half-sine)

to EN 60068-2-29/03.95

150 m/s² (492 ft/s²), 6 ms,

1000 shocks/axis

• Noise (digitally controlled)

to EN 60068-2-64/08.95

10 ... 200 Hz;

1 (m/s²)²/Hz (3.28 (ft/s²)²/Hz)

200 ... 500 Hz;

0.3 (m/s²)²/Hz (0.98 (ft/s²)²/Hz)

4 hours/axis

• Recommended continuous duty

range of the complete fitting

≤ 30 m/s² (≤ 98.4 ft/s²) without reso-

nance sharpness

Weight, basic device

• Glass-fiber-reinforced Makrolon

enclosure

Approx. 0.9 kg (1.98 lb)

• Aluminum enclosure

Approx. 1,3 kg (2.86 lb)

• Stainless steel enclosure

Approx. 3.9 kg (8.58 lb)

• Pressure-proof alum. enclosure

Approx. 5.2 kg (11.46 lb)

Dimensions

See Dimensional drawings

Climatic class

According to DIN EN 60721-3-4

• Storage

1)

1K5, but -40 ... +80 °C

(-40 ... +176 °F)

• Transport

1)

2K4, but -40 ... +80 °C

(-40 ... +176 °F)

• Operation

2)

4K3, but -30 ... +80 °C

3)

(-22 ... +176 °F)

Certificates and approvals

Classification according to pres-

sure equipment directive

(PED 97/23/EC)

For gases of fluid group 1, complies

with requirements of article 3, par. 3

(sound engineering practice SEP)

CE marking

You can find the appropriate guidelines

and standards applied, including the

relevant versions, in the EC Declaration

of Conformity on the Internet

Pneumatic data

Auxiliary power (air supply)

Compressed air, nitrogen or cleaned

natural gas

• Pressure

1.4 ... 7 bar (20.3 ... 101.5 psi):

Sufficiently greater than max. drive

pressure (actuating pressure)

Air quality to ISO 8573-1

• Solid particulate size and density Class 2

• Pressure dew point

Class 2 (min. 20 K (36 °F) below

ambient temperature)

• Oil content

Class 2

Unrestricted flow (DIN 1945)

• Inlet air valve (ventilate actuator)

4)

- 2 bar (29 psi)

4.1 Nm³/h (18.1 USgpm)

- 4 bar (58 psi)

7.1 Nm³/h (31.3 USgpm)

- 6 bar (87 psi)

9.8 Nm³/h (43.1 USgpm)

• Outlet air valve (vent actuator)

4)

- 2 bar (29 psi)

8.2 Nm³/h (36.1 USgpm)

- 4 bar (58 psi)

13.7 Nm³/h (60.3 USgpm)

- 6 bar (87 psi)

19.2 Nm³/h (84.5 USgpm)

Valve leakage

< 6⋅10

-4

Nm³/h (0.0026 USgpm)

Throttle ratio

Adjustable up to ∞ : 1

Auxiliary power consumption in

the controlled state

< 3,6⋅10

-2

Nm³/h (0.158 USgpm)

Device versions

• In Makrolon enclosure

Single-acting and double-acting

• In aluminum enclosure

Single-acting

• In pressure-proof aluminum encl. Single-acting and double-acting

• In stainless steel enclosure

Single-acting and double-acting

Gauge made of

Plastic

Steel

Stainl. Steel 316

Degree of protection IP31

IP44

IP54

Vibration resistance

acc. to DIN EN 837-1