Bray 6A Series O&M Manual User Manual

Page 27

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

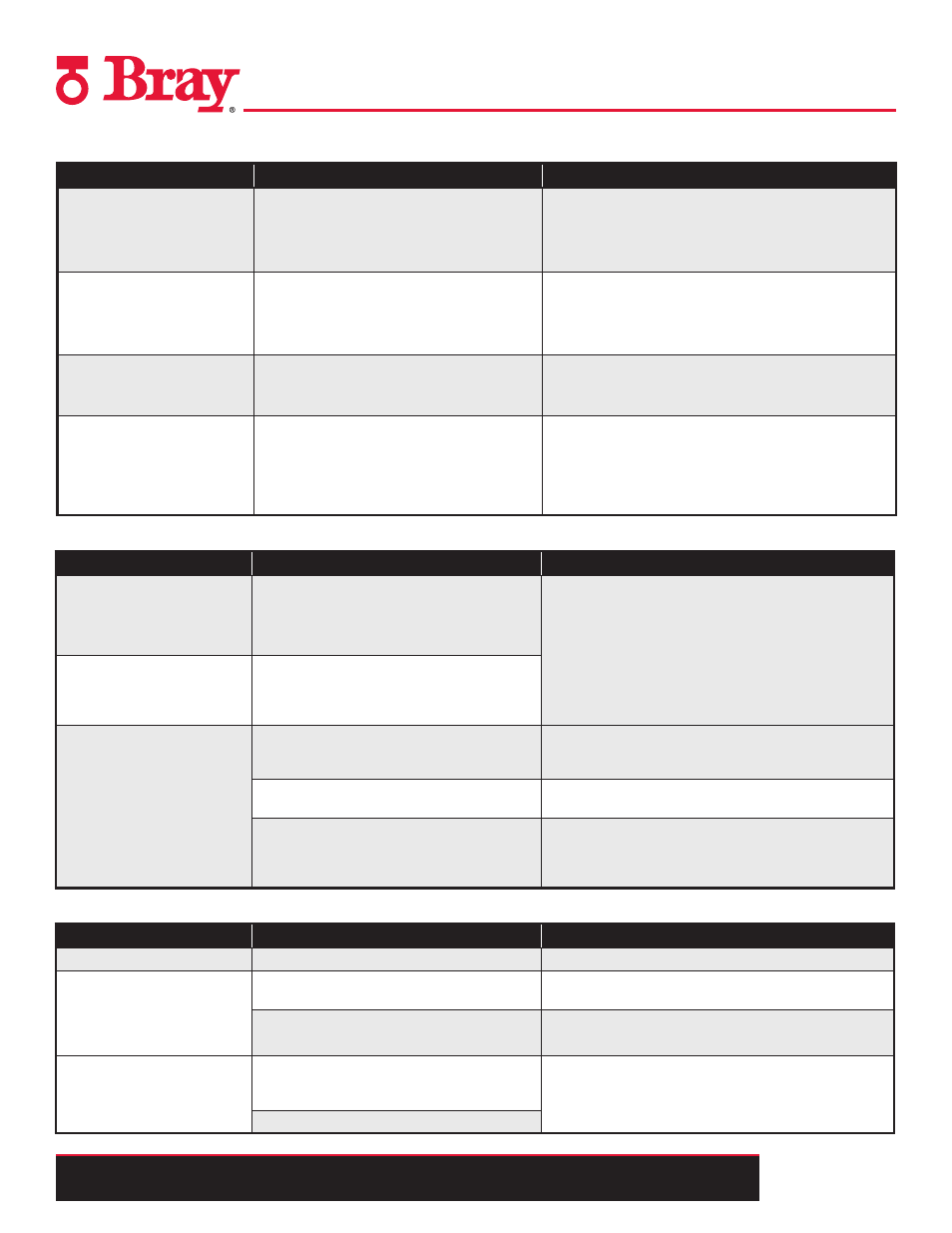

Series 6A Operation & Maintenance – Troubleshooting

6A O & M : 27

Fault profile (symptoms) Possible cause(s)

Remedial measures

Positioner remains in “RUN 1”. Initialization started from the end position

The response time of a maximum of 1 minute was

not observed

Network pressure not connected or it is too low

A waiting time of up to 1 minute is essential

Do not start initialization from the end position

Provide the network pressure

Positioner remains in “RUN 2”. Transmission ratio selector and parameter 2 do

not match the actuator type.

Incorrectly set stroke on the lever

Piezo valve does not activate

Check settings: see leaflet: “Device view (7)” picture as well

as parameters 2 and 3

Check the stroke setting on the lever. See table 2

Positioner remains in “RUN 3”. Actuator actuating time is too high

Open the restrictor completely and/or set the pressure PZ (1)

to the highest permissible value

Use a booster if required

Positioner remains “RUN 5”,

does not go up to “FINISH”

(waiting time > 5 min)

“Gap” (play) in the positioner - actuator - control

valve system

Part-turn actuator: check for the firmness of the grub screw

of the coupling wheel

Linear actuator: check for the firmness of the lever on the

positioning shaft

Remove any play between the actuator and the control valve.

Remedial Measures Table 1

Fault profile (symptoms) Possible cause(s)

Remedial measures

“CPU test” blinks on the digital

display approximately every two

seconds.

Piezo valve does not activate.

Water in the pneumatic block (due to wet com-

pressed air)

At an early stage, this fault can be rectified with a subsequent

operations using dry air, if required, in a temperature cabinet

at 50 to 70°C

Otherwise: repair

1)

In the manual and automatic

modes, the actuator cannot be

moved or can be moved only in

one direction

Moisture in the pneumatic block

Piezo valve does not activate (a

gentle click sound is not audible

when the “+” or “-” buttons are

pressed in the manual mode.)

The screw between the shrouding cover and the

pneumatic block has not been tightened firmly or

the cover got stuck

Tighten the screw firmly; if required realign cover.

Dirt (swarf, particles) in the pneumatic block

Repair or a new device; clean and/or replace the built-

in fine screens

Deposits on the contacts between the electronic

printed circuit board and the pneumatic block

may develop due to abrasion owing to continuous

loads resulting from strong vibrations

Clean all contact surfaces with spirit; if required, bend

the pneumatic block contact springs

Remedial Measures Table 2

Fault profile (symptoms) Possible cause(s)

Remedial measures

Actuator does not move.

Compress air < 1.4 bar

Set the supply air pressure to >20 psi

Piezo valve does not activate (a

gentle click sound is however

audible when the “+” or “-” but-

tons are pressed in the manual

mode.)

Restrictor valve turned off (screw at the right end

stop)

Open the restrictor screw by turning it counter clockwise, see

leaflet, “Device view (6)”

Dirt in the pneumatic block

Repair

1)

or a new device: clean and/or replace the built-in

fine screens

A piezo valve activates

constantly in the stationary auto-

matic mode (constant setpoint)

and the manual mode.

Pneumatic leakage in the positioner - actua-

tor system; start the leakage test in “RUN3”

(initialization).

Rectify leakage in the actuator and/or feed line.

In case of an intact actuator and tight feed line; repair

1)

or a

new device

Dirt in the pneumatic block, see above

Remedial Measures Table 3