Series 6a operation & maintenance – technical data, 6a o & m : 32 – Bray 6A Series O&M Manual User Manual

Page 32

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Series 6A Operation & Maintenance – Technical Data

6A O & M : 32

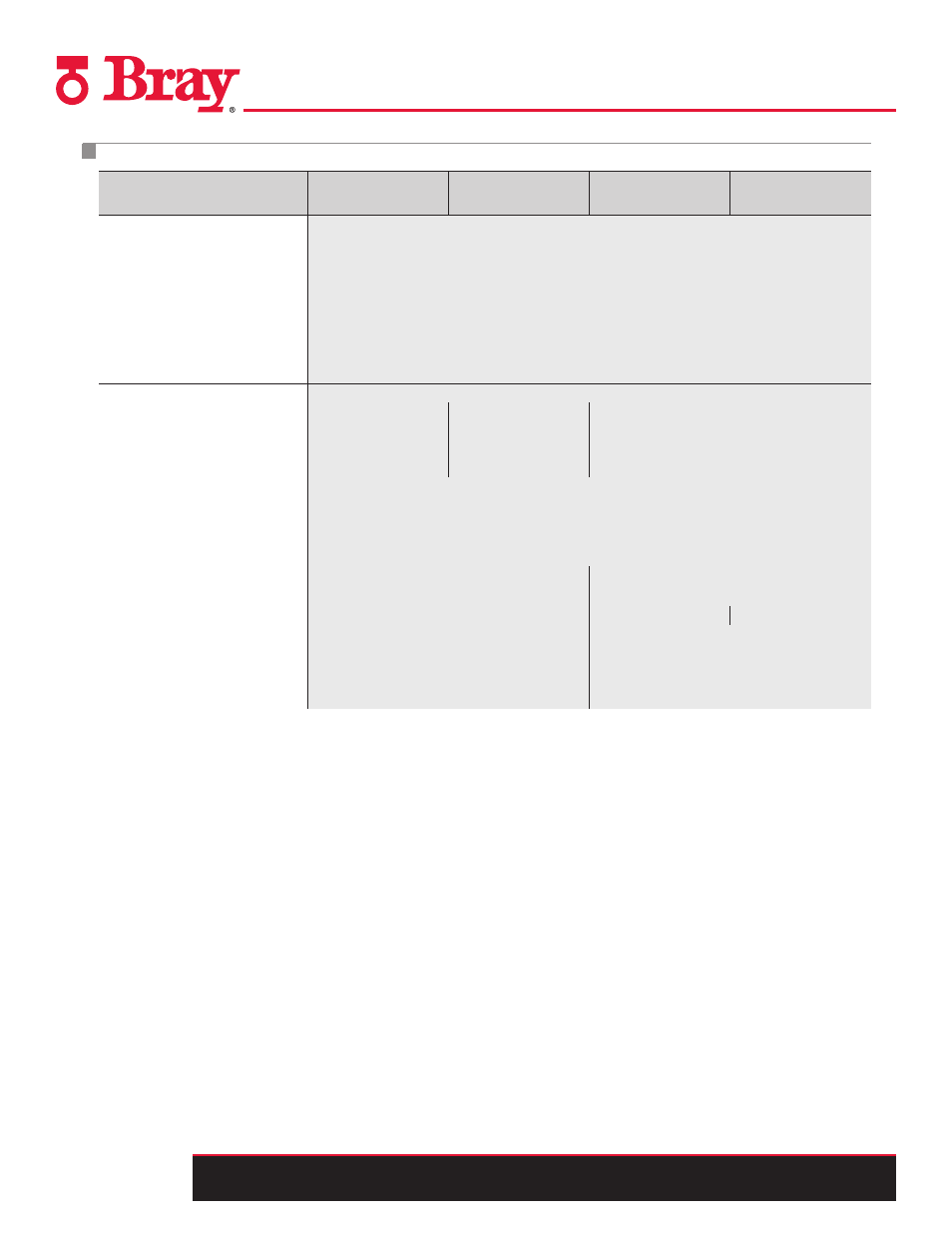

Communication

Layers 1 and +2 according to PROFIBUS PA, transmission technology according to IEC 1158-2;

slave function; layer 7 (protocol layer) according to PROFIBUS DP,

EN 50170 standard with the extended PROFIBUS functions

(all data acyclic, manipulated variable, feedbacks and status also cyclic)

C2 connections

Four connections to master class 2 are supported,

automatic connection setup 60 s after break in communication

Device profile

PROFIBUS PA profile B, version 3.0, more than 150 objects

Response time to master message

Typically 10 ms

Device address

126 (when delivered)

PC parameterizing software

SIMATIC PDM, supports all device objects. The software is not included in the scope of delivery

Connections

• Electrical

Screw terminals 2.5

AWG28-12

Cable gland M20x1.5 or

½-14 NPT

Screw terminals 2.5

AWG28-12

Ex d certified cable gland

M20x1.5, ½-14 NPT or

M25x1.5

Screw terminals 2.5 AWG28-12

Cable gland M20x1.5 or ½-14 NPT

• Pneumatic

Female thread G¼

EN ISO 228-1

(¼ -18 NPT)

External position sensor (potentiome-

ter or NCS; as option) with the follow-

ing peak values

• U

o

–

5 V

• I

o

(static)

–

75 mA

• I

s

(short-time)

–

160 mA

–

• P

o

–

120 mW

• Maximum permissible external

capacitance C

o

–

1 μF

• Maximum permissible external

inductance L

o

–

1 mH

SIPART PS2 PA

Basic device

without Ex protection

Basic device

with Ex d protection

(flameproof enclosure)

Basic device

with Ex ia/ib protection

Basic device

with Ex n/

dust protection

Technical specifications