Notice – Bray 6A Series O&M Manual User Manual

Page 24

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Series 6A Operation & Maintenance – Installable Options

6A O & M : 24

NotICe

A pin in the actuating disc bearing is pressed. Align this pin

before it touches the special screw. You must rotate the actuat-

ing disc bearing and the special screw simultaneously so that the

pin is inserted into the special screw.

7. An insulating cover is provided over the SIA unit. Place the

insulating cover to one side under the motherboard seat on

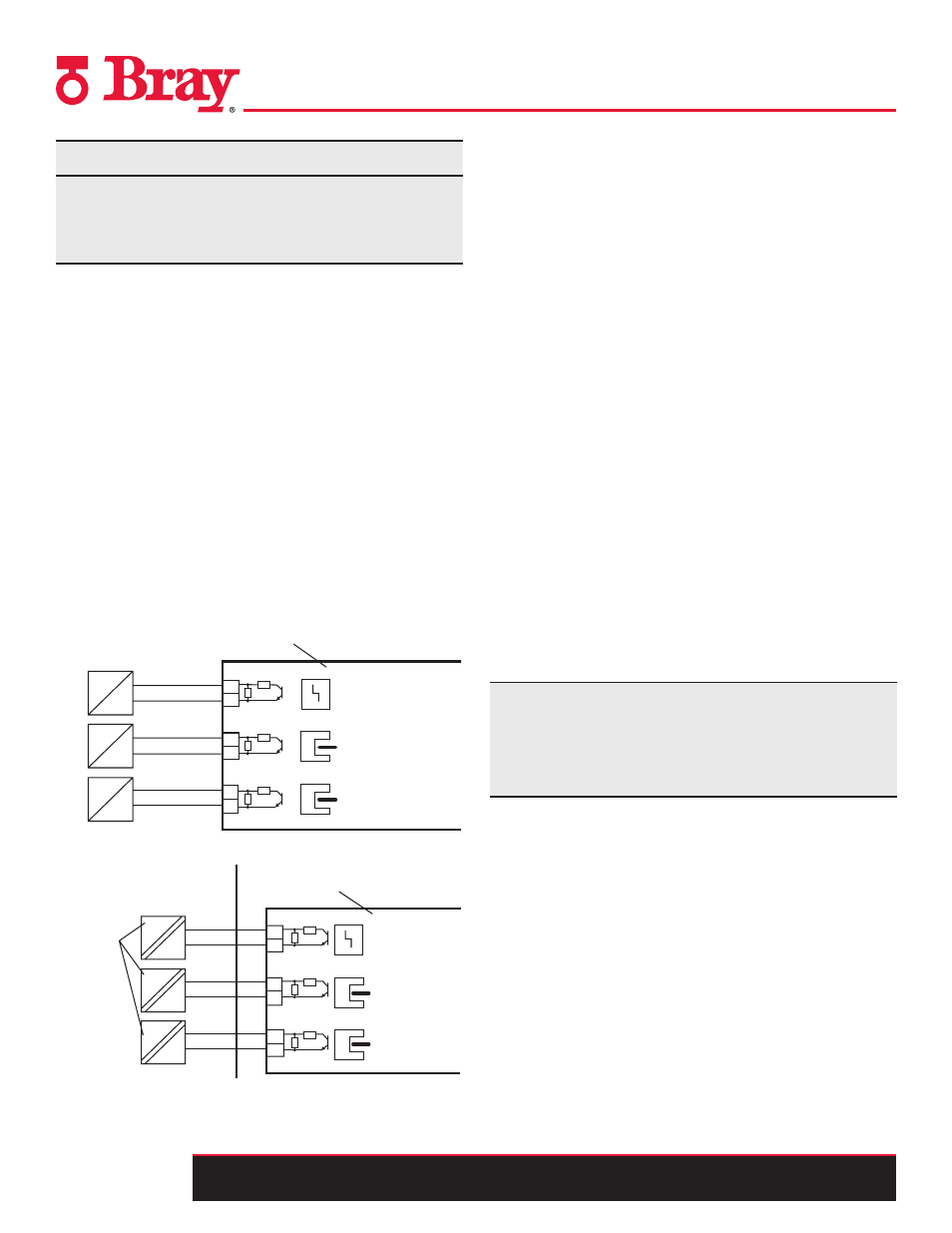

the container wall. The recesses of the insulating cover must

fit in the corresponding webs of the container wall.

8. Place the insulating cover on the SIA unit by bending the

container walls carefully.

9. Engage the motherboard into the four brackets.

10. Tighten the motherboard using the two screws.

11. Reestablish all electrical connections between the mother-

board and the optional modules. Connect the motherboard

and the optional modules to the ribbon cables provided.

Connect the motherboard and the potentiometer to the poten-

tiometer cable.

12. Using both the screws, fasten the module cover provided. Do

not use the standard module cover.

13. Refer to Figures 14 and 15 to connect the SIA module in stan-

dard and intrinsically safe applications

31

32

41

42

51

52

2K1

10K

< 35 V

8,2 V

8,2 V

+

+

+

Fault message

Limit value A1

Limit value A2

Switching amplifier according to EN 60947-5-6

SIA module

6DR4004-8G

#

#

#

31

32

41

42

51

52

8,2 V

8,2 V

8,2 V

SIA module

6DR4004-6G

Fault message

Limit value A1

Limit value A2

2K1

10K

Intrinsically safe

switching

amplifier to DIN

EN 60947-5-6

Non-hazardous area

Hazardous area, zone 1 or zone 2

EEx

EEx

EEx

+

+

+

#

#

#

Setting The Limits Of The Slotted Initiator Alarm Unit

You will require a suitable display device to determine the switch

status. For example, use the initiator tester type 2 / Ex by Pepperl

+ Fuchs.

1. Connect the display device to the following terminals of the

SIA unit:

• 41 and 42

• 51 and 52

2. Read the switch status of slotted initiators

Proceed as follows to set the limits:

1. Move the actuator to the first desired mechanical position.

2. Adjust the upper actuating disc manually until the output

signal at terminals 41 and 42 changes. Set a high-low or a

low-high switch over as follows:

• Rotate the actuating disc beyond the switching point

until you reach the next switching point.

3. Move the actuator to the second desired mechanical position.

4. Adjust the lower actuating disc manually until the output

signal at terminals 51 and 52 changes. Set a high-low or a

low-high switch over as follows:

• Rotate the actuating disc beyond the switching point

until you reach the next switching point.

Note: The actuating discs are relatively difficult to move. This

design prevents their unintentional movement during operation.

You can achieve an easier and finer adjustment by reducing

friction temporarily. Move the actuator to and fro while

simultaneously holding the actuating discs.

Figure 14 - SIA unit 6DR4004-8G, not Ex

Figure 15

-

SIA unit 6DR4004-6G, EEx i