Bray 6A Series O&M Manual User Manual

Page 19

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Series 6A Operation & Maintenance – Calibration & Commissioning

6A O & M : 19

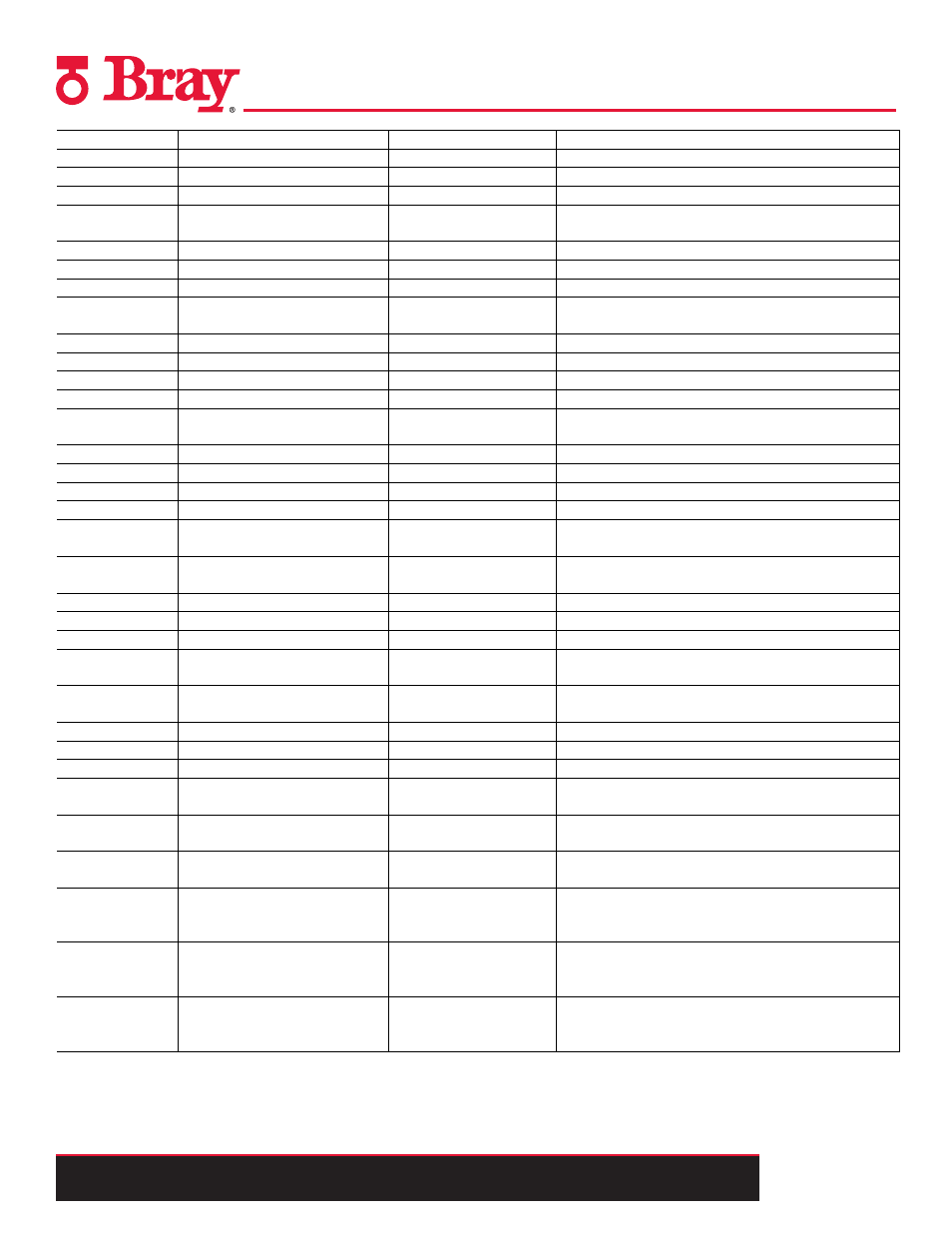

F. ZERO

Zero point monitoring

Activates the zero point displacement test

F1.LEVEL1

Threshold 1

0.1 … 1.0 … 100.0

Sets a threshold in % of the lower hard stop. “1.0”

F2.LEVEL2

Threshold 2

0.1 … 2.0 … 100.0

Sets a threshold in % of the lower hard stop “2.0”

F3.LEVEL3

Threshold 3

0.1 … 4.0 … 100.0

Sets a threshold in % of the lower hard stop “4.0”

G. OPEN

Displacement of the upper

stop

Activates the test to monitor the displacement of the

upper end stop.

G1.LEVEL1

Threshold 1

0.1 … 1.0 … 100.0

Sets a threshold in % of the upper hard stop. “1.0”

G2.LEVEL2

Threshold 2

0.1 … 2.0 … 100.0

Sets a threshold in % of the upper hard stop. “2.0”

G3.LEVEL3

Threshold 3

0.1 … 4.0 … 100.0

Sets a threshold in % of the upper hard stop. “4.0”

H. TMIN

Monitoring of the lower limit

temperature

Activates the test to continuously monitor the lower

limit temperature

H1.TUNIT

Temperature Unit

Sets the temp. parameter from “C” to “F”. “C”

H2.LEVEL1

Threshold 1

-40 … 194

Sets a threshold in degrees “C” or “F”. “-25 C”

H3.LEVEL2

Threshold 2

-40 … 194

Sets a threshold in degrees “C” or “F”. “-30 C”

H4.LEVEL3

Threshold 3

-40 … 194

Sets a threshold in degrees “C” or “F”. “-40 C”

J. TMAX

Monitoring of the upper limit

temperature

Activates the test to continuously monitor the upper

limit temperature

J1.TUNIT

Temperature Unit

Sets the temp. parameter from “C” to “F”. “C”

J2.LEVEL1

Threshold 1

-40 … 194

Sets a threshold in degrees “C” or “F”. “75 C”

J3.LEVEL2

Threshold 2

-40 … 194

Sets a threshold in degrees “C” or “F”. “80 C”

J4.LEVEL3

Threshold 3

-40 … 194

Sets a threshold in degrees “C” or “F”. “90 C”

L. STRK

Monitoring the path integral

Monitors the entire path covered by the final

controlling element.

L1.LIMIT

Limit for the number of

changes of direction

1 … 1E6 … 1E8

Sets the base limit for the number of strokes. “1.00

E6”

L2.FACT1

Factor 1

0.1 … 1.0 … 40.0

Factor for the formation of limit threshold 1. “1.0”

L3.FACT2

Factor 2

0.1 … 2.0 … 40.0

Factor for the formation of limit threshold 2. “2.0”

L4.FACT3

Factor 3

0.1 … 5.0 … 40.0

Factor for the formation of limit threshold 3. “5.0”

O. DCHG

Monitoring the changes in

direction

Continuously monitors the number of changes of

direction of the actuator caused in the dead zone.

O1.LIMIT

Limit for the number of

changes of direction

1 … 1E6 … 1E8

Sets the base limit for the number of changes of

direction. “1.00 E6”

O2.FACT1

Factor 1

0.1 … 1.0 … 40.0

Factor for the formation of limit threshold 1. “1.0”

O3.FACT2

Factor 2

0.1 … 2.0 … 40.0

Factor for the formation of limit threshold 2. “2.0”

O4.FACT3

Factor 3

0.1 … 5.0 … 40.0

Factor for the formation of limit threshold 3. “5.0”

P. PAVG

Position mean value

calculation

Activates the test to calculate and monitor the

position average

P1.TBASE

Time base of the mean value

generation

.5h / 8h / 5d / 60d / 2.5y Sets the time interval to calculate the position

average

P2.STATE

State of the position mean

value calculation

IdLE/ rEF / ###.# / Strt Starting time for the calculation of position average.

“IdLE”

P3.LEVEL1

Threshold 1

0.1 … 2.0 … 100.0

Sets a threshold for the maximum deviation of the

current position average from the reference avg.

“2.0”

P4.LEVEL2

Threshold 2

0.1 … 5.0 … 100.0

Sets a threshold for the maximum deviation of the

current position average from the reference avg.

“5.0”

P5.LEVEL3

Threshold 3

0.1 ..10.0..100.0

Sets a threshold for the maximum deviation of the

current position average from the reference avg.

“10.0”