Overview, Site requirements – Franklin Fueling Systems LS500 Auto Learn Line Leak Detection Installation & Users Guide User Manual

Page 5

5

Overview

The TS-LS500 is a continuous product line leak detection system that monitors the primary pipe. This product is an

available option of Franklin Fueling Systems’ TS-550 and TS-5000 FMS consoles.

The TS-LS500 system includes the FMS application running on a T5 series console and a transducer. One transducer

is required per product line, which measures the line pressure. Line Pressure is created by the pump and static seating

pressure is metered by a pressure relief valve. Transducers (TS-LSU500) use the AutoLearn technology to continuously

evaluate the line conditions.

Note: The TS-LS500 requires pressure for leak tests and should only be installed in systems that are designed to obtain

and hold this minimum static pressure. The system will report “learned with errors” if tests are run at less than

optimum pressure.

Applications

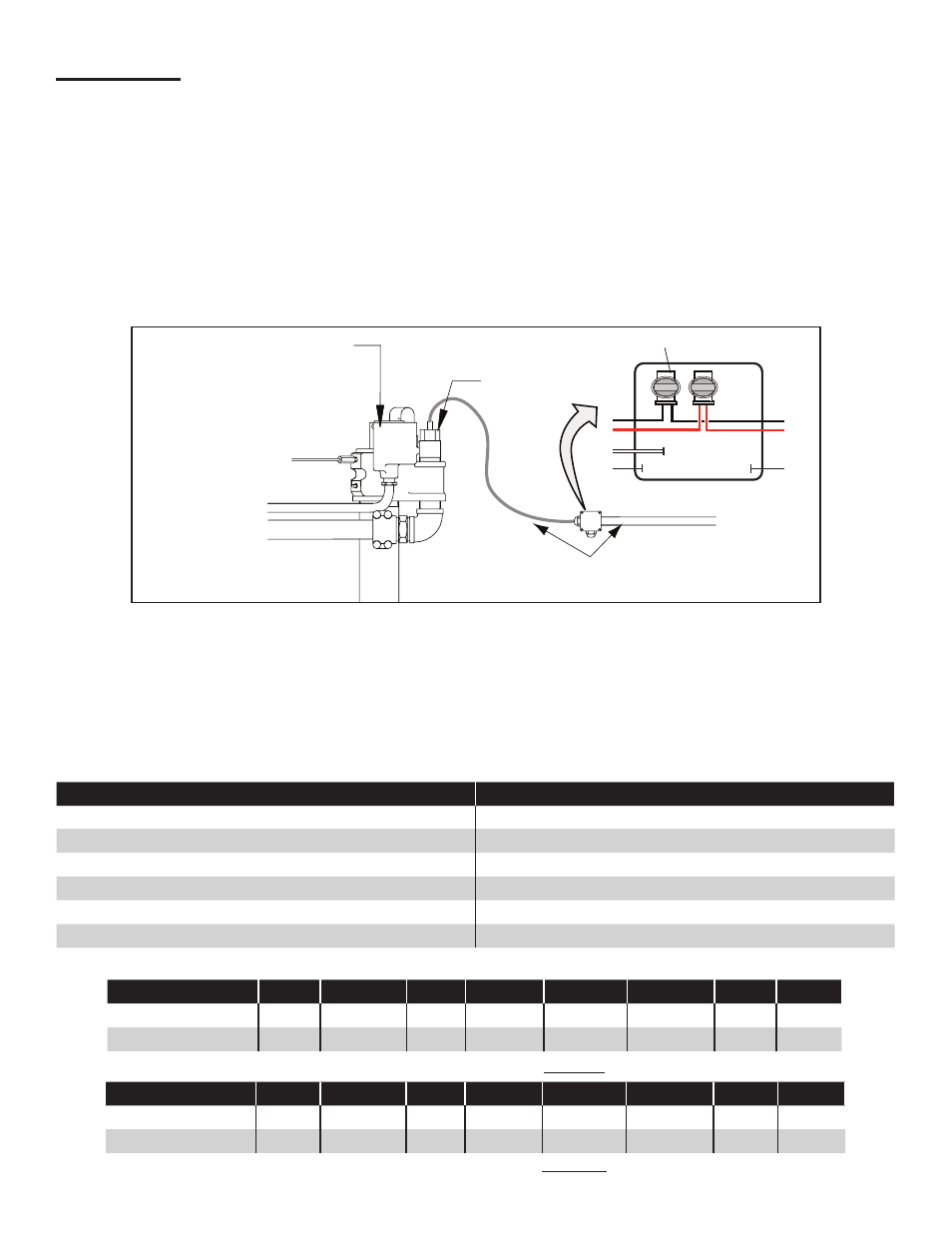

The following diagram illustrates a typical installation of the LS500 equipment inside of a STP sump.

TS-LSU500

Pump

Submersible

FE Petro

Intrinsically safe wiring or explosion-proof

conduit, depending upon application

Wire Splices

White (capped)

Shield (Not connected)

Red

Black

Figure 1: LS500 Install Overview

To maintain optimal line pressure, Franklin Fueling makes the following recommendations for submersible pumps:

• For FE Petro Submersible Pumps, use a Standard Check Valve (part # 400988931).

• For Red Jacket Submersible Pumps, use an adjustable functional element, adjusting the pump OFF pressure to be at

least 2 psi below the pump ON pressure.

Newer style Red Jacket Submersible Pumps do not have an adjustable functional element as an option. These

submersible pumps have a check valve that meets the LS500 pressure requirements.

Site Requirements

Item

Value

Minimum Static Pressure

18 PSI for precision testing

15 PSI for gross leak testing

20 PSI for learning lines

Maximum line volume for rigid pipe

312.2 gallons

Maximum line volume for flexible pipe

95.4 gallons

Minimum volume for rigid or flexible pipe

2.5 gallons

Table 1: Capacity Table

Pipe Diameter I.D.

1"

1 ½" 1 ¾"

2"

2 ½"

3"

4"

5"

Flex Length

61'

27'

20'

15'

10'

7'

4'

2'

Rigid Length

61'

27'

20'

15'

10'

7'

4'

2'

Table 2: Pipe Length Required for Holding Minimum Line Volume

Pipe Diameter I.D.

1"

1 ½"

1 ¾"

2"

2 ½"

3"

4"

5"

Flex Length

2339'

1040'

764'

585'

374'

260'

146'

94'

Rigid Length

7656'

3403'

2500'

1914'

1225'

851'

479'

306'

Table 3: Pipe Length Required for Holding Maximum Line Volume