Franklin Fueling Systems LS500 Auto Learn Line Leak Detection Installation & Users Guide User Manual

Page 21

21

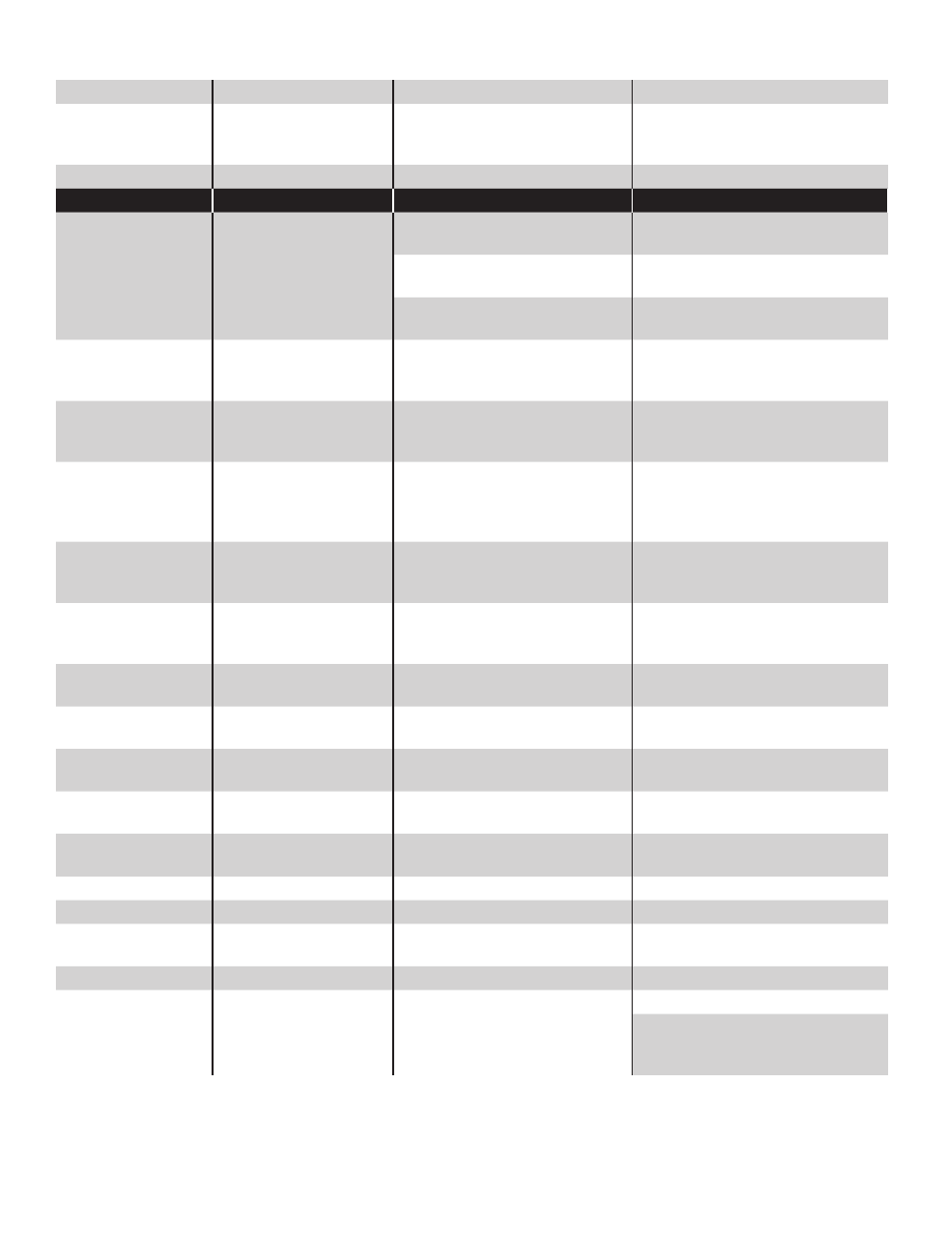

Catastrophic leak

Investigate for leaks

Is the clamp valve down

Look at the pressure gauge on

the needle valve kit for operating

pressure

Test Result

Condition

Possible Cause

Resolution

Failed to catch

pressure

Pressure was less

that 12 psi after

programmed delay

when STP turned off

Check valve damaged

Investigate, force a manual test

and observe pressure

Dispenser solenoid is still open

after hook signal is off

Dispense, release hook, keep

nozzle open

Catastrophic leak

Investigate for a catastrophic leak

such as a pipe breaking

Sudden Pressure

Loss

Pressure dropped to

less than 5 psi

Catastrophic leak

Monitor line pressure using a

pressure gauge, investigate for

leaks

Dispensing Pressure

Test Failed

Pressure dropped to

less than 7.5 psi while

dispensing

Monitor line pressure using a

pressure gauge, investigate for

leaks

High Pump Pressure Pressure was above

50 psi during the catch

pressure test 3 times

consecutively

Monitor line pressure using a

pressure gauge, investigate for

faulty check valve

Extended Hook

Signal

Hook signal was applied

for more than 4 hours

Dispenser hook signal on steady Verify that all handles are down,

test AC inputs to determine which

is giving a signal

Pressure Transducer

Fail

Communication failure

to transducer

Wiring

Check wiring connections at the

console, junction box and quick

disconnect.

Transducer failure

Direct connect, if still in alarm,

replace.

Air in line

Console has Sensed

Line Pressure Variations

Line left open or air elimination

loop failing

Investigate, then Purge Line

Starting at the Furthest Dispenser

Not Enabled

Line disabled

Either manually, or by another

application shut the STP down

Check other alarms, find source of

interruption

Marginal Pass of

Gross Leak Test

Passing result of gross

test, but marginally

Line is not thermally stable

Force a gross leak test

Pump Request

Ignored

STP did not turn on

when requested

Controller not functioning

System is busy

TPI problem

Check RS485 communication

STP is disabled by another

application

4-20 mA Input error

Contact Technical Support

Module is Offline

Communication failure

between the control

module and the module

offline

Look at module LEDs

Red, replace module.

Green solid or flashing, power

down the console and re-seat the

module

Operating Alarms (Continued)