Clearing alarms – Franklin Fueling Systems LS500 Auto Learn Line Leak Detection Installation & Users Guide User Manual

Page 22

22

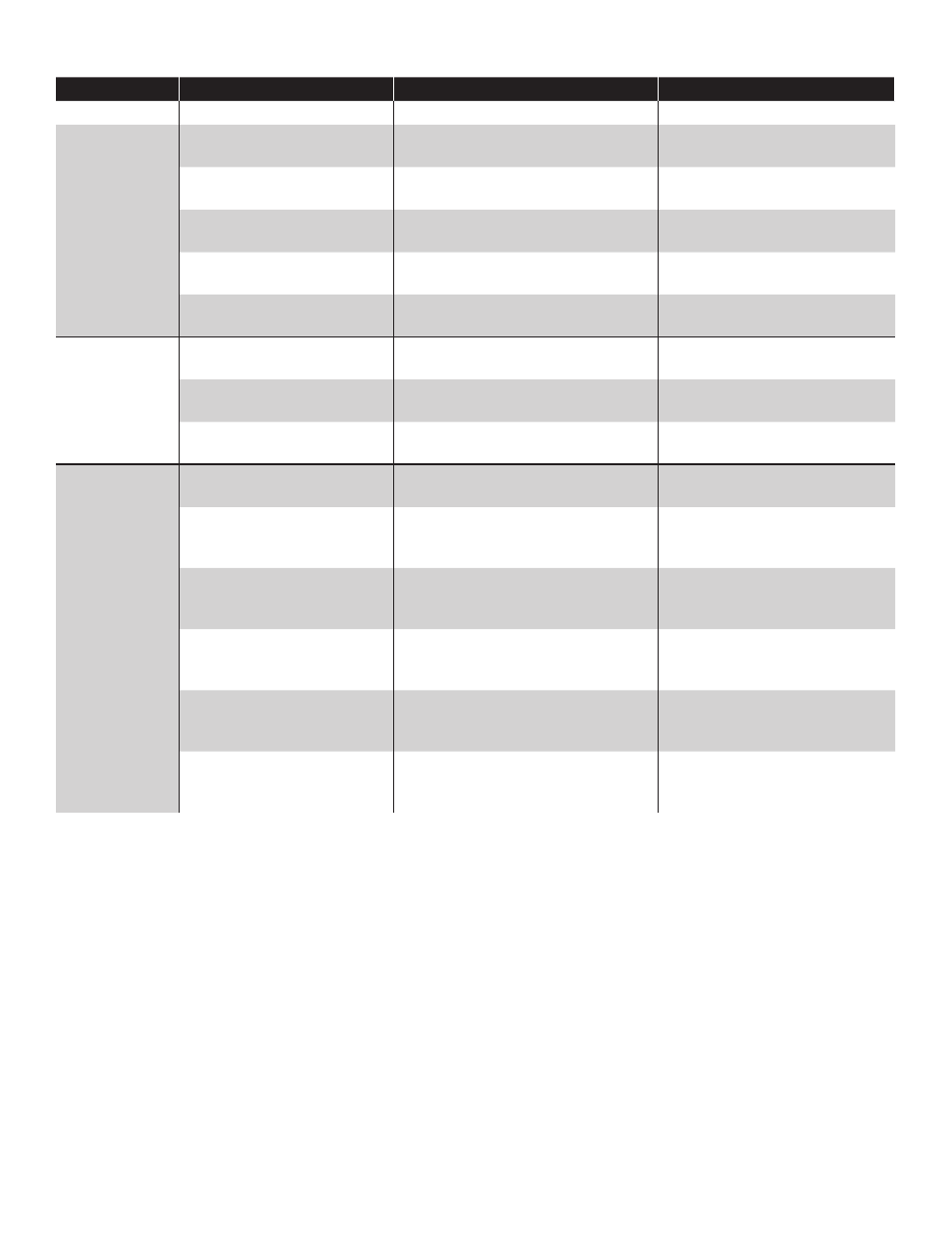

Test Result Alarms

Test Result

Condition

Possible Cause

Resolution

Pass

Line is tight

Fail

Actual Leak

Line pressure variations are outside

threshold

Check for leaks, force leak test

to verify

Temperature Instability

Temperature fluctuations cause

pressure variances

Check for leaks, force leak test

to verify

Inadequate learning

Line not properly bled to zero during

learning

Re-learn the line, follow

procedures

Air was not bled out of the line prior

to learning

Purge the line, re-learn

Air in line

Line left open or air elimination loop

failing

Purge the line

Abort (no

indication)

Dispensing

A hook signal was detected, this

resets the testing

Allow test cycle to complete

before dispensing

Line disabled

Either manually, or by another

application shut the STP down

Check other alarms, find source

of interruption

Manual test started

User forced a line leak test

Cycle resets after manual test

completes

STP Shutdown 2 consecutive 3 GPH test

failures

Possible gross leak

Investigate, then Force a

Manual Gross Test

1-2 consecutive 0.2 GPH

test fails (depending on

programming)

Possible 0.2 GPH leak

Investigate, then Force a

Manual Monthly Test

1-3 consecutive 0.1 GPH

test fails (depending on

programming)

Possible 0.1 GPH leak

Investigate, then Force a

Manual Annual Test

3 consecutive catch pressure

tests that over 50 psi

High line pressure

Investigate, adjust or replace

check valve or functional

element

Catch pressure test failure

Pressure was less that 12 psi after

programmed delay when STP

turned off

Investigate, force a manual test

and observe pressure

Pressure up test failure

Pressure was less that 12 psi after

programmed delay when STP

turned on

Investigate, force a manual test

and observe pressure

Clearing Alarms

Clearing a console of alarms is important because, depending on how the T5 Series FMS console has been set up,

alarms can: disable channels, start an annunciator, or stop a line test under way.

Administrator privileges will be necessary to clear line alarms on the T5 Series FMS console. For instructions on how to

obtain an Administrator access level, please refer to the T5 Series FMS Programming Guide (p/n 000-2142) or the TS-

550evo FMS Programming Guide (p/n 000-2173).

1. Identify the alarm on the FMS Alarms screen.

2. Diagnose the condition using information found in the Alarms chapter of this guide.

3. Follow the troubleshooting steps in the previous section of this chapter to correct the issues indicated by the alarms.

4. Navigate to the Line Control screen.

5. Select

Reset Alarms on the Control screen.

6. Select

Enable/Disable on the Control screen if you were not given the choice to enable the line when the alarms were

reset.

If the condition still exists, the alarm can take up to several hours to reappear after the line is enabled.