Franklin Fueling Systems LS500 Auto Learn Line Leak Detection Installation & Users Guide User Manual

Page 13

13

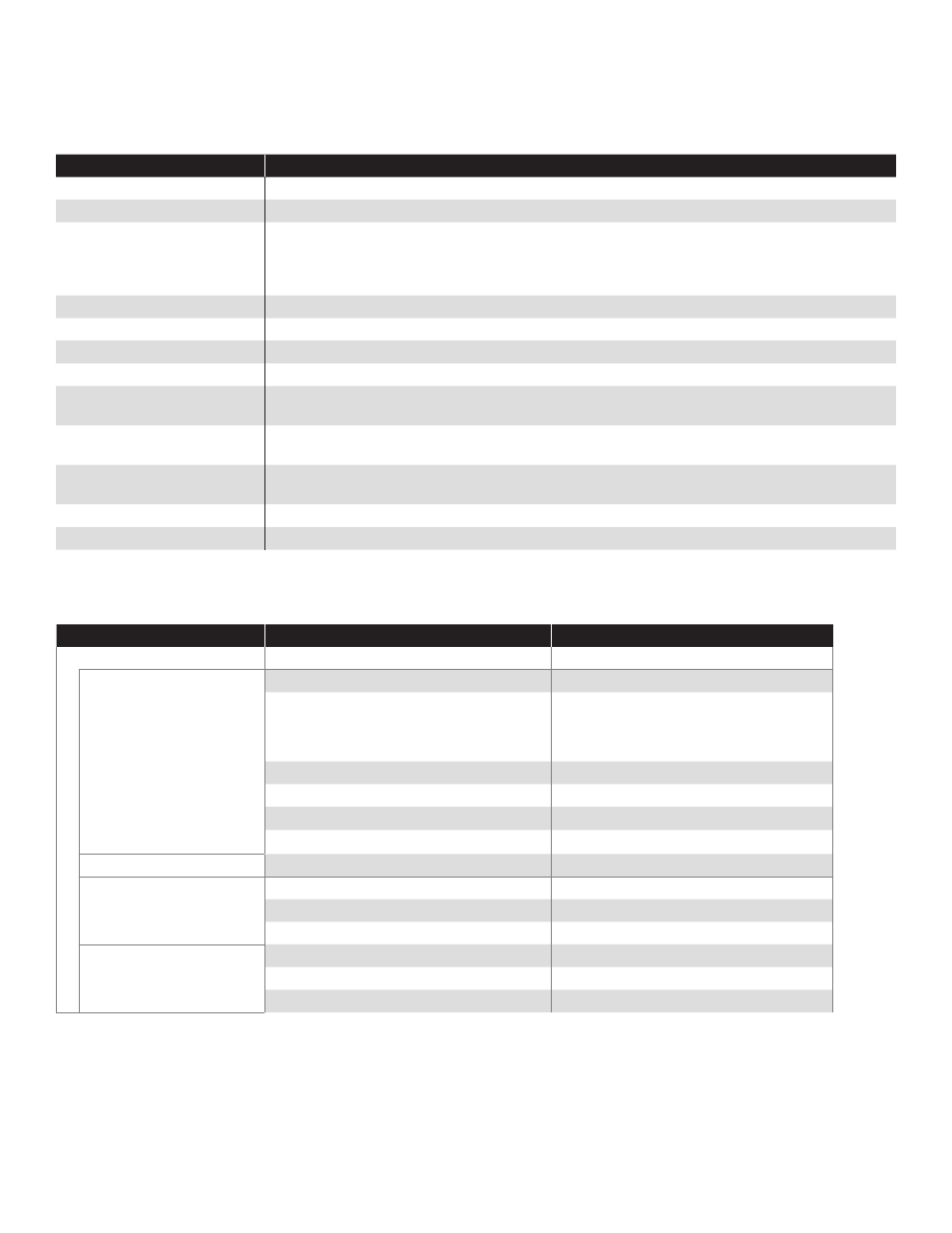

Fuel Management Systems (FMS) Line Application Set-Up

Setting up the lines establishes which transducer and relay is used on the specific line and allows the user to change

certain parameters in the operation of the line leak testing. Make sure the line is holding at or above the minimum required

pressure (see page 5). If the pressure is too low, review the check-valve used, and adjust the pump / pump controller for

proper pressure.

Parameter

Parameter Value

Number of lines

Number of product lines

Name

Text box, name each channel to easily identify in the mapping.

Submersible Pump Module

Select either power supply module or relay module depending upon which relay is being used for

pump control, or if TPI is being used. If Power Supply Board is selected and a relay from this power

supply board was associated to a pump, an additional option will show up to indicate if TPI or relay

will be used.

Submersible Pump Channel

Select the channel that the submersible controller is connected to.

Transducer

Select the transducer installed in the line.

Enabled

Select yes

Pressure Up Test Wait Time *

Default is 4 Seconds. This is the time that the gauge waits for the line to pressure up above 12 PSI.

Catch Pressure Wait Time *

Default is 2 seconds. This is the time the gauge waits after the pump turns off to make sure the

pressure is at least 12 PSI.

Dispenser Pressure Test

When selected, this gauge monitors the line pressure while dispensing. If the pressure decreases to

7.5 PSI, the line goes into alarm mode. The pump shuts off and is disabled.

Gross / Monthly / Annual Tests

Enable

Select Yes. This allows the LS500 to run the tests.

Wait Period Between Tests

Default setting is 0 days. (This is the scheduling for line test after the test passed).

Shutdown on Test Fail

If selected, this will shut down the submersible if that line fails that type of test

* These settings typically will not need to be changed. Contact FFS tech support before changing these settings.

Example: LS500 Application Setup

Group Name

Parameter Name

Parameter Value

Lines

Number of lines 3

Line 1

Name Unleaded Line

Submersible Pump Module Relay Module

Submersible Pump Channel Unleaded STP

Transducer

Unleaded Transducer

Enabled Yes

Pressure Up Test Wait Time 4 Sec

Catch pressure Wait Time 2 Sec

Dispenser Pressure Test

Yes

Gross Tests

Enable Yes

Monthly Tests

Enable yes

Wait Period Between Passed Tests 0 Days

Shutdown on Failed Test

Annual Tests

Enable Yes

Wait Period Between Passed Tests 0 Days

Shutdown on Failed Test

Note: Do not enable the line in set-up until the transducers have been properly connected to the 4-20 Input Module.