Learn process, When to learn / re-learn, Procedure – Franklin Fueling Systems LS500 Auto Learn Line Leak Detection Installation & Users Guide User Manual

Page 17

17

Learn Process

Each line must be learned before the FMS system can continuously monitor it. Learning involves bleeding the line

pressure down to zero, with no air in the line, then introducing a calibrated leak, facilitated by the leak generating kit (TS-

ALCAL). The system learns this pressure decay curve and uses it to compare test data during continuous operation to

determine if there is a leak in the line.

Note: All console programming must be completed prior to the learn process. Refer to the Setup (Console Programming)

chapter in this manual for details. Administrator privileges are necessary to Learn Lines. Refer to T5 Series FMS

Programming Guide (p / n 000-2142) or the TS-550evo FMS Programming Guide (p/n 000-2173). for information on

gaining Administrator privileges.

Note: Complete the Pre-Operation Line Testing chapter prior to starting the Learn Process.

Note: No dispensing can take place during the Learn Process. If product is dispensed while Learning, stop the process

by pressing the

Stop button.

Note: DO NOT submerse or block the TS-ALCAL orifice while learning the line. The orifice MUST be kept free of dirt and

debris.

When to Learn / Re-Learn

• Line installation and start-up

• After repairs or modifications that effect the operating or holding pressure of the line

• After 4-20mA Input Module replacement

• After certain 4-20mA Input Module firmware upgrades (consult FFS Technical Services Department)

• If moving the LS-500 to another 4-20mA channel

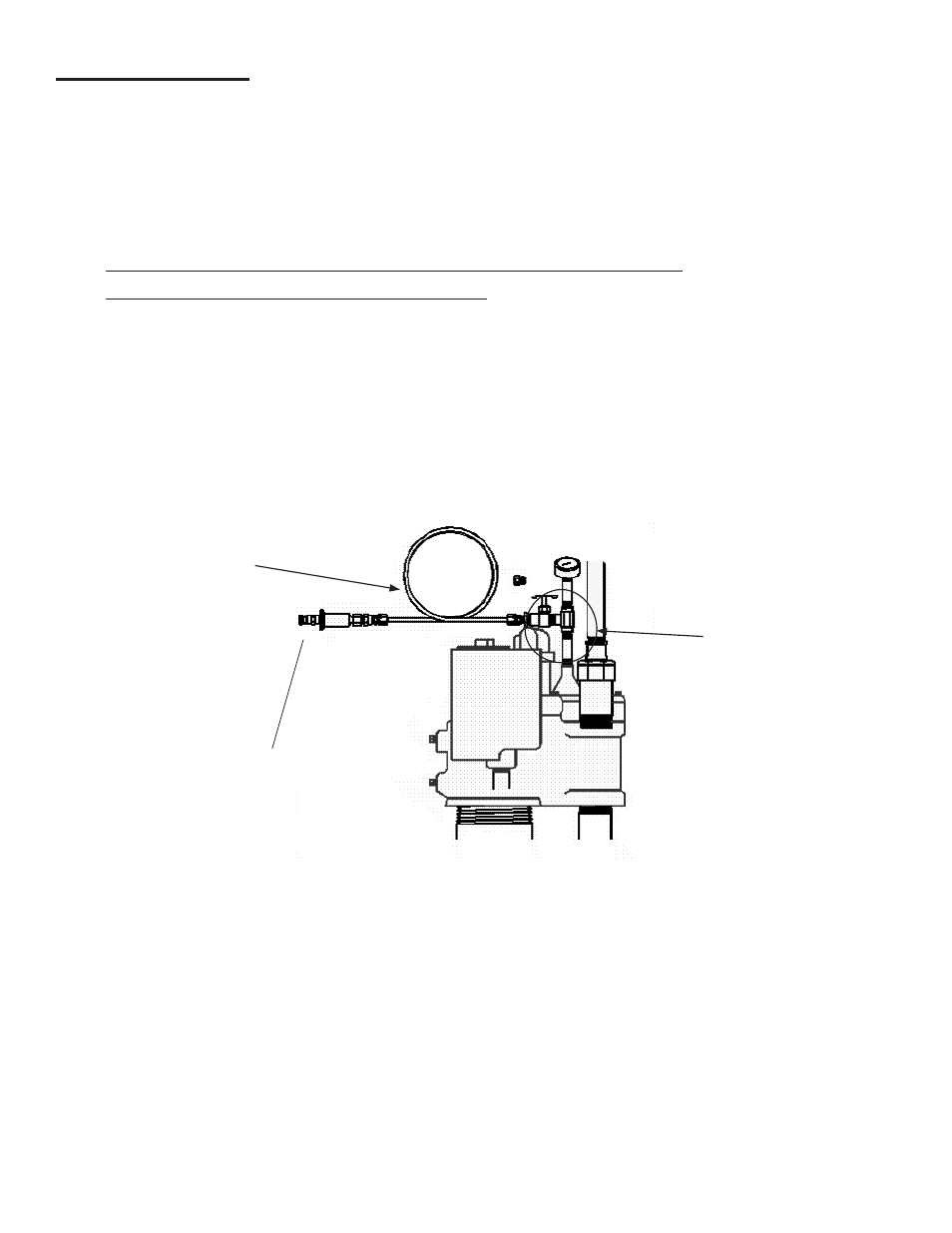

Figure 4 – Leak Generator Kits

Procedure

1. The needle valve kit (TS-ALNIP) and 3.0 GPH Leak Generator (TSP-ALCAL) should be installed in the STP

manifold. The line must be purged of all air prior to learning the line.

2. Open the needle valve with the leak generator in an approved container to catch any product. Let the line

pressure bleed down to 0. Make sure that the pressure reads 0 on the pressure gauge installed on the needle

valve kit.

3. Navigate to the line control screen on either the touch screen or by the web page. Locate the learn section and

press start.

4. If the learn process is performed correctly the screen will show the events in the following sequence,

• Learning zero offset

• Turn the STP on

• Learn pump pressure

• Learn the pressure decay curve

TS-ALCAL

TS-ALNIP

Place a container to

catch the product