Franklin Fueling Systems T5 Series Fuel Management System Operators Guide User Manual

Page 34

30

FMS

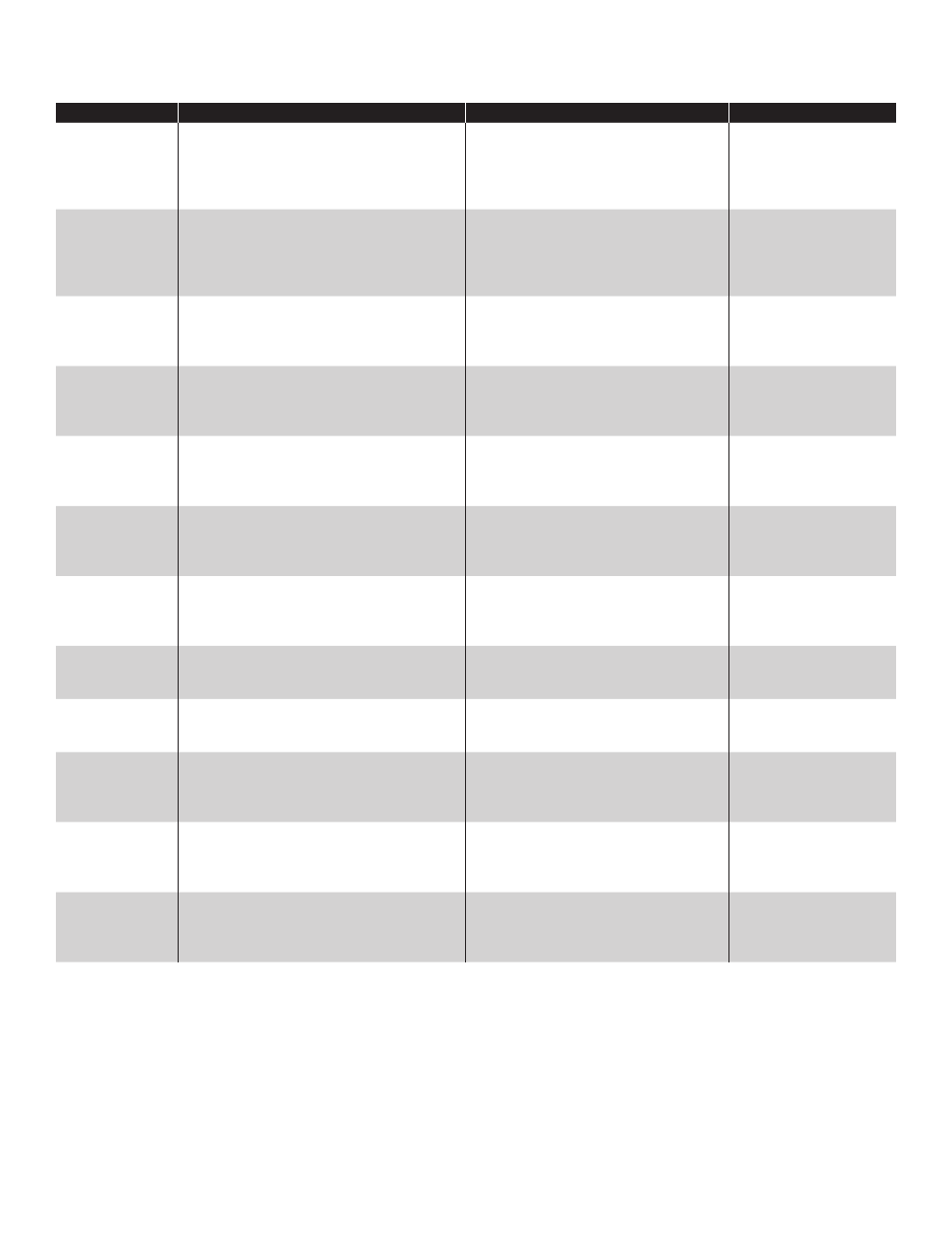

Probe Alarms

Displayed Alarm

Description

Recommended Actions

Reference Source

Float Height

Error

A float on the probe listed with the alarm is

being monitored at a varying height outside

of thresholds. Causes can include broken

float and programming, or mistakenly

associating a gasoline and diesel float.

Verify Probe programming. Visually

inspect that the probe float type matches

the type of product. Inspect magnet and

probe shaft for cracks or debris and

clean if necessary.

Probes Setup in

Programming Manual)

/ Applicable Equipment

Guide*

Float Missing

A float on the probe listed with the alarm

has not been detected or the probe was

programmed with the incorrect number of

floats.

Verify the ‘number of floats’ in Probe

programming. Number of floats must

match number of floats installed. Float

must be lower than 5" from the bottom of

the probe head.

Probes Setup in

Programming Manual /

Applicable Equipment

Guide*

High Water

Level

The water float on the Tank/Manifold listed

with the alarm is above the programmed

High Water Level Limit.

Verify that the programmed limit is

correct. Verify that the Water Level

values on the console correspond with

the actual water level in the tank.

Probes Setup in

Programming Manual /

Applicable Equipment

Guide*

High Product

Level

The product float on the Tank/Manifold listed

with the alarm is above the programmed

High Product Level Limit. Tank may be close

to an overfull condition.

Verify that the programmed limit is

correct. Verify that the Gross Product

Level values on the console correspond

with actual product level in the tank.

Probes Setup in

Programming Manual /

Applicable Equipment

Guide*

High High

Product Level

The product float on the Tank/Manifold listed

with the alarm is above the programmed

High High Product Level Limit. Tank may be

near an overfull condition.

Verify that the programmed limit is

correct. Verify that the Gross Product

Level values on the console correspond

with actual product level in the tank.

Probes Setup in

Programming Manual /

Applicable Equipment

Guide*

Low Product

Level

The product float on the Tank/Manifold listed

with the alarm is above the programmed

Low Product Level Limit. Tank may be close

to an empty condition.

Verify that the programmed limit is

correct. Verify that the Gross Product

Level values on the console correspond

with actual product level in the tank.

Probes Setup in

Programming Manual /

Applicable Equipment

Guide*

Low Low

Product Level

The product float on the Tank/Manifold listed

with the alarm is above the programmed

Low Low Product Level Limit. Tank may be

near an empty condition.

Verify that the programmed limit is

correct. Verify that the Gross Product

Level values on the console correspond

with actual product level in the tank.

Probes Setup in

Programming Manual /

Applicable Equipment

Guide*

No Probe

Detected

This alarm indicates a communication error

between the console and the probe listed

with the alarm.

Verify Probe programming. Inspect the

probe wiring from the probe module to

the probe.

Probes Setup in

Programming Manual /

Installation Guide

Probe

Synchronization

Error

This alarm indicates a communication error

between the console and the probe listed

with the alarm.

Verify Probe programming. Inspect the

probe wiring from the probe module to

the probe.

Probes Setup in

Programming Manual /

Installation Guide

RTD Table Error The RTD Table programmed for the probe

listed with the alarm is incorrect.

Verify the RTD Table programming.

Probes Setup in

Programming Manual /

Applicable Equipment

Guide*

Temperature

Error

This alarm indicates a temperature sensor

error or failure inside the probe shaft of the

probe listed with the alarm.

Verify the RTD Table programming.

Visually inspect probe shaft for defects

and cracks.

Probes Setup in

Programming Manual /

Applicable Equipment

Guide*

Unstable Probe This alarm indicates inconsistent data from

the probe listed with the alarm.

Inspect the probe wiring from the probe

module to the probe. Verify that the

product in the tank is both physically and

thermally stable.

Installation Guide /

Applicable Equipment

Guide*

* Bulletins and the T5 Series Installation Guide (p/n 000-2150) and the T5 Series Programming Manual (000-2142) can be found on

Franklin Fueling’s web site - http://www.franklinfueling.com/service/. Select Technical Documentation / Fuel Management System