Test cycles & types, How to manually start line leak tests – Franklin Fueling Systems T5 Series Fuel Management System Operators Guide User Manual

Page 24

20

Test Cycles & Types

Once installed, calibrated and enabled, the LS500 will start a cycle of tests after the hook signal becomes inactive (i.e. a

nozzle is hung up). The transducers then monitor line pressure to ensure that pressure is sufficient to proceed with the

cycle. A Gross (3.0 GPH) Leak Test will begin immediately following the pressure test, if these options are enabled in

setup. When the Gross Test is complete with a pass result, the system will wait 30 minutes prior to monitoring the line for

thermal stability. When it determines that the line is stable, another Gross Test will be performed directly followed by a

Monthly (0.2 GPH) Leak Test. When the Monthly Test is complete with a pass result, the system then monitors the line for

thermal stability once again. When that the line is stable, another Gross Test will be performed followed by an Annual (0.1

GPH) Leak Test. When the Annual Test is complete with a pass result, the system then waits 45 minutes prior to restarting

the cycle again.

Test Type

Description

Pressure Up

A pressure up test will monitor line pressure from a static line to when the pump is turned on.

Dispenser Pressure

Dispenser pressure is tested with the hook applied to ensure that line pressure does not drop too

low while dispensing. This feature can be enabled/disabled in the programming.

Catch Pressure

When the dispenser hook is dropped and the pump turns off, line pressure decay is monitored and

compared to a learned decay. This test will not cause the pump to shut down — alarm only.

Gross (3.0 GPH) Leak

The Gross Test will begin after every dispense when the line is enabled or after every 45 minutes

of quite time (no dispensing or pump running) following a line pressure test. In ideal conditions, this

test will take approximately 5 minutes to complete. In the event of a failure, the system will attempt

to run the test again after 5 minutes. After two failures an indicator light and alarm will turn on and

the pump will be shutdown. A dispense or pump shutdown by another application during this test

will cause an Abort Alarm. This test can be enabled / disabled in the programming.

Thermal Wait Time

Before initiating a precision test, the LS500 will monitor the line for thermal variations. Testing for

thermal variations takes 1½ to 10 hours of inactivity.

Monthly (0.2 GPH) Leak

If this option is enabled in the programming, the test will follow a thermal wait period and line

pressure test. In the event of a failure, the system will attempt to run the test again without

waiting. Upon three failures, an indicator light and alarm will turn on and the pump will shutdown if

programmed. A dispense or pump shutdown by another application during this test will cause an

Abort alarm. This test can be enabled/disabled in the programming.

Annual (0.1 GPH) Leak

Line Learned but Not Enabled If a line is learned and not enabled within a preset amount of time, then the console will show a

warning that the line is not enabled. This is to show that the line is not being monitored for leaks.

Sudden Pressure Loss

This is a continuous test that runs in the background. An alarm will occur if line pressure drops too

fast.

Extended Pump Run

The LS500 will detect all hook signals (if wired properly) and the time that they remain active. If

the hook signal is active for too long, the console will indicate this condition with an alarm light and

sound.

High Pressure

If line pressure exceeds the maximum allowable pressure, the pump will shut down and an alarm

will light and sound. This test will run continuously when the line is enabled.

How to Manually Start Line Leak Tests

This procedure requires User level privileges.

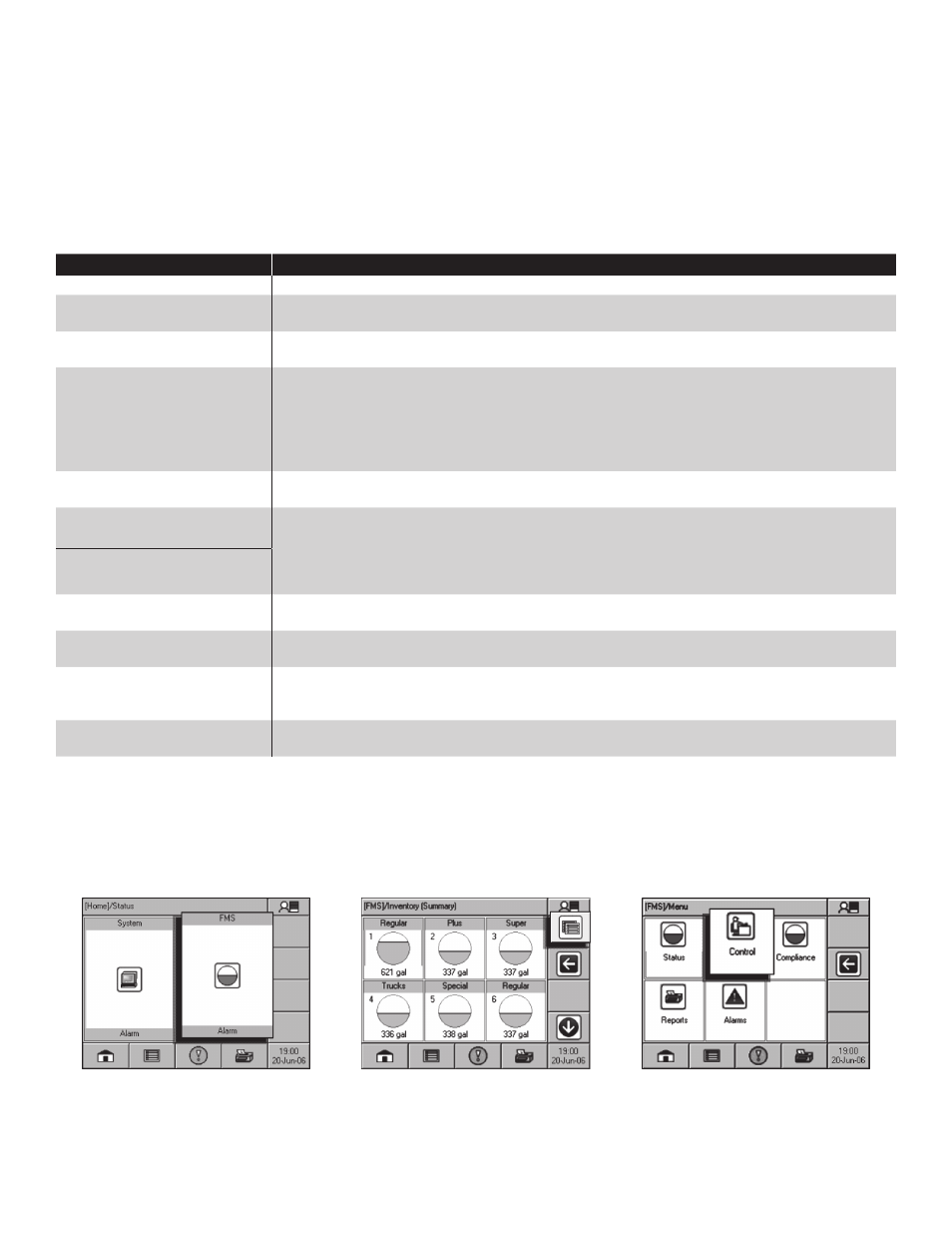

1. Starting at the Home/Status screen, press the FMS application button.

2. Press the Application Menu button.

3. Press the Control button.

Step 1

Step 2

Step 3