Franklin Fueling Systems Colibri CL6 Setup and Operators Guide User Manual

Page 13

13

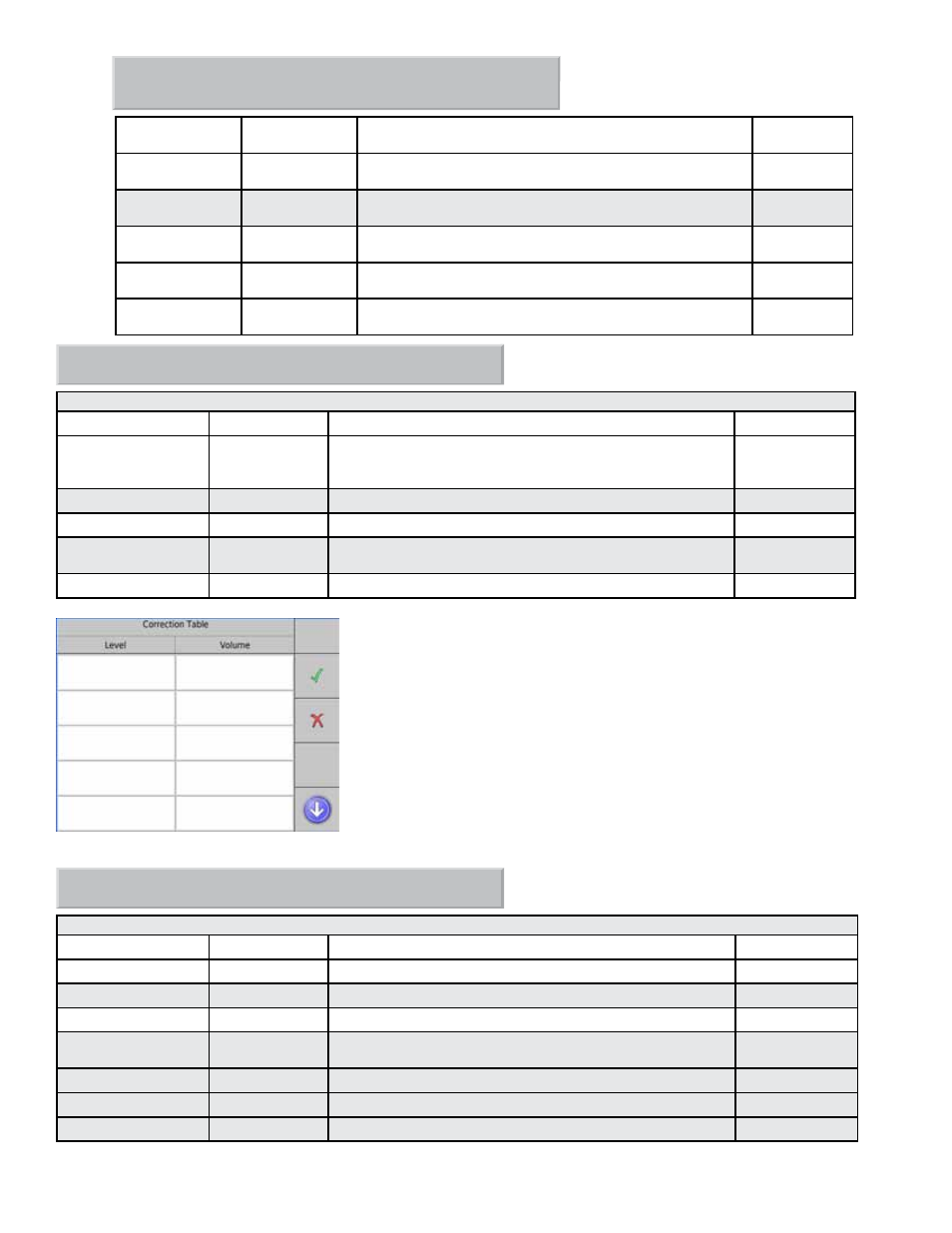

[Setup] / Fuel Management System / Tanks /

Tank 1 / Limits

Parameter Name Parameter

Value

Description

Value

High High Product

(Level) Limit

(63.5 liter) (cm) Product level needed to cause alarm. Units depend on

whether Level or Volume was chosen for high product limit.

# liters (cm)

High Product

(Level) Limit

(58.4 liter) (cm) Product level needed to produce alarm. Units depend on

whether Level or Volume was chosen for high product limit.

# liters (cm)

High Water Level

Limit

(5.1 cm)

Water level needed to produce alarm.

# cm

Low Product

Volume Limit

(847.9 liter)

Product level needed to produce alarm. Units depend on

whether Level or Volume was chosen for low product limit.

# Liters (cm)

Low Low Product

Volume Limit

(832.8 liter)

Product level needed to produce alarm. Units depend on

whether Level or Volume was chosen for low product limit.

# Liters (cm)

[Setup] / Fuel Management System / Special Tanks

Special #

Parameter Name

Parameter Value

Description

Value

Shape

(Horizontal

Cylinder)

Choose tank shape

Horizontal or

Vertical Cylinder,

Rectangular

Length

(160)

Enter Tank Length

0-1200 in.

Diameter

(28)

Enter Tank Diameter

0-1200 in.

End Type

(Cylinder)

Describe tank end type

Cylinder, one or

two domed ends

Correction Table

Number of points

0-100

Note: For the following information, Setup / Fuel Management System / Tanks / Manifolded must be set to Yes.

[Setup] / Fuel Management System / Manifolds

Manifold #

Parameter Name

Parameter Value

Description

Value

Name

(Manifold 1)

Enter manifold name

abc#

Product #

(1)

Product # In tank

1 - 48

Delivery Threshold

(757.1)

Level increase needed to signal delivery

# liters

Theft Threshold

(18.9)

Level decrease needed to signal theft. Note: console must be in

Sentinel Mode

# liters

Monthly Compliance

Yes

Track this manifold under monthly section of compliance page

Yes / No

Limits

Sets high and low level limits (see table top of page 11)

SCALD

Enable, Qualify and Diagnostic Modes

Note: SCALD (Statistical Continuous Automatic Leak Detection) tank test runs continuously and requires and detects

quiet times of no dispensing or deliveries.

The Correction Table is used to adjust tank

characteristics by correlating known volume with

a known level. The table is more reliable when

more points are known.