Inspections and maintenance, 1 list of inspections, Type of the inspection – GE Industrial Solutions GERAPID 8007R, 10007R WITH ARC CHUTES 1X2, 1X3 User Manual

Page 29

2010-02-16 DTR01807 rev.02

Design and specifications are subject to change without notice

29

6. Inspections and maintenance

6.1 List of inspections

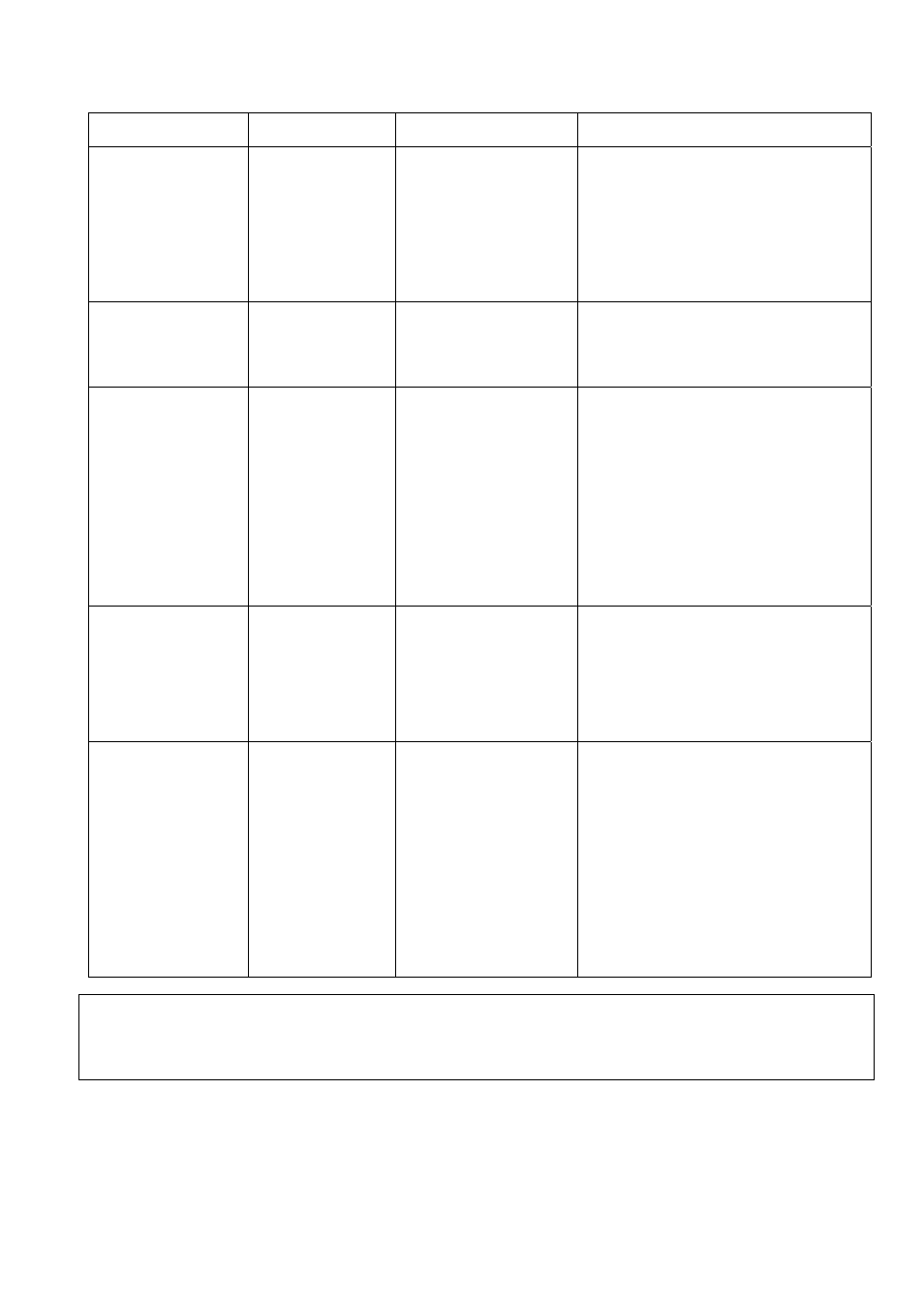

TYPE OF THE

INSPECTION

BY WHOM

HOW OFTEN

WHAT TO DO/CHECK

A. General visual

inspection

-Customer

-Trained technician

At least once a year.

•

Check for damages or cracks of the

frame, adapter or arc chute

•

Check for missing screws or caps

•

Check for damaged labels

•

Check for corrosion

•

Check for distinct manifestations of flame

or smoke at the frame

•

Clean the breaker from dirt and dust

•

Clean and degrease the copper terminals

B. General functional

inspection

-Customer

-Trained technician

At least once a year.

•

Manually close and open the breaker to

check the drive and mechanism

•

Close the breaker electrically and open by

trip unit(s) releasing, to check controls

•

Check the blockade of POCT

C. Inspection of the arc

chute and contact

system

-Customer

-Trained technician

After:

•

high short circuit

opening over 25 kA

•

300 openings at load

current or frequent

overload switching.

At least once a year.

•

Check for wear of the arc probes; shall not

exceed 30 % of its cross section

•

Check for wear of the pre-arcing contact.

It shall not exceed 2 mm [0.08 in].

•

Check for wear of the main contacts at

fixed and flexible sides; shall not exceed

1.5 mm [0.06 in] of its depth.

•

Check for wear of the arc chute plates;

check for deposits inside of arc chute, this

area shall be free of deposits.

•

Check for wear of protective walls; shall

not exceed 1 mm [0.04 in].

•

Check for contact tilt and gaps.

D. Inspection of the

screw/bolt connections

-Customer

-Trained technician

After every inspection:

•

of the arc probes

•

of the contacts

•

of the arc chute

At least once a year.

Check the position of the countersunk screws

in the sidewalls.

Check for tightness or use torque tool (torque

in SI and Imperial units):

•

M8 ~20 Nm [~ 177 in-lbs]

•

M6 ~10 Nm [~ 88 in-lbs]

•

M5 ~5 Nm [~ 44 in-lbs]

•

M4 ~3 Nm [~ 26 in-lbs]

E. Inspection of the

mechanic components

-GE

-Service technician

After 5.000 openings

At least once every 4

years

•

Carry out inspection “B” above

•

Check out settings of the main contacts

and auxiliary switch

•

Check out upper dumper of the

mechanism; no cracks, deformation or

heavy discoloration; hard consistency;

without punctures

•

Check out main flexband breakage; shall

not exceed 30 % of its cross section

•

Check out wear of mini flexband; shall not

exceed 30 % of its cross section

•

Clean and degrease UVR latch and quick

latch of the mechanism. Apply dash of

Beacon EP2 grease afterwards.

Required tools:

Cleaning tissue; abrasive paper; manual closing lever; metric hex (Allen) wrenches SW5, SW6; Torx® wrenches size T30,T 40, T45;

small and medium screwdrivers; ratchet with 10 mm hex socket; pliers; tongs.

Dispose of the breakers if required:

Pay attention to the national and local regulations of disposal!