GE Industrial Solutions Arc Vault Protection System User Manual

Page 46

Arc Vault™ Protection System

DEH-41483 Rev. 3

Maintaining the Switchgear

38

© 2011 General Electric All Rights Reserved

2. Check all bolts that hold cable terminals to the

connection bars for tightness.

3. Check the ground bus connection and mounting bolts

for tightness.

4. Check that all secondary control wiring connections

are tight and that all control cabling is intact.

OVERALL EQUIPMENT

Make the following checks on the complete switchgear

equipment.

1. Clean and inspect all painted surfaces and retouch

where necessary.

2. Check to see that all anchor bolts and other structural

bolts are tight.

3. Check that all device and instrument compartment

door latches operate properly.

4. If the switchgear is equipped with heaters, check to see

that all heaters are energized and operating.

PAINT REFINISHING

Indoor switchgear is finished with ANSI-61 gray acrylic

enamel paint (PPG W42713, GE part number 21525032650).

To refinish damaged areas, remove all loose paint, rust,

scale, oil or grease. Sand any scratches smooth using 220

grit paper or finer.

1. Apply a coat of good acrylic enamel primer (Sherman-

Williams E61 A 60,-GE part number 21525025200) with

a viscosity of approximately 24-32 seconds using a #2

Zahn cup. Reduce with D5B9 Xylol (GE part number

21525038000) if needed. Air dry the primer for a

minimum of 30 minutes, then apply the finish color coat

of acrylic enamel. The top coat should be applied within

24 hours for best adhesion.

2. If the area is to be spray-coated, thin the acrylic

enamel with D5B9 Xylol (GE part number 21525038000).

This thinning should only be necessary if the paint was

received in a five gallon drum or more The

recommended viscosity for the W42713 topcoat should

be 24-32 seconds with a #2 Zahn cup. The curing

schedule for PPG W42713 is dust free in 5 minutes,

touch in 30 minutes, handle in 60 minutes, full cure in 7

days. Both the primer (Sherwin-Williams E61 A 60) and

paint (PPG W42713) should be applied only when

temperature is above 55 degrees Fahrenheit.

3. Application of special paint will be per the

manufacturer’s Product Data Sheet which includes

instructions on thinning and application.

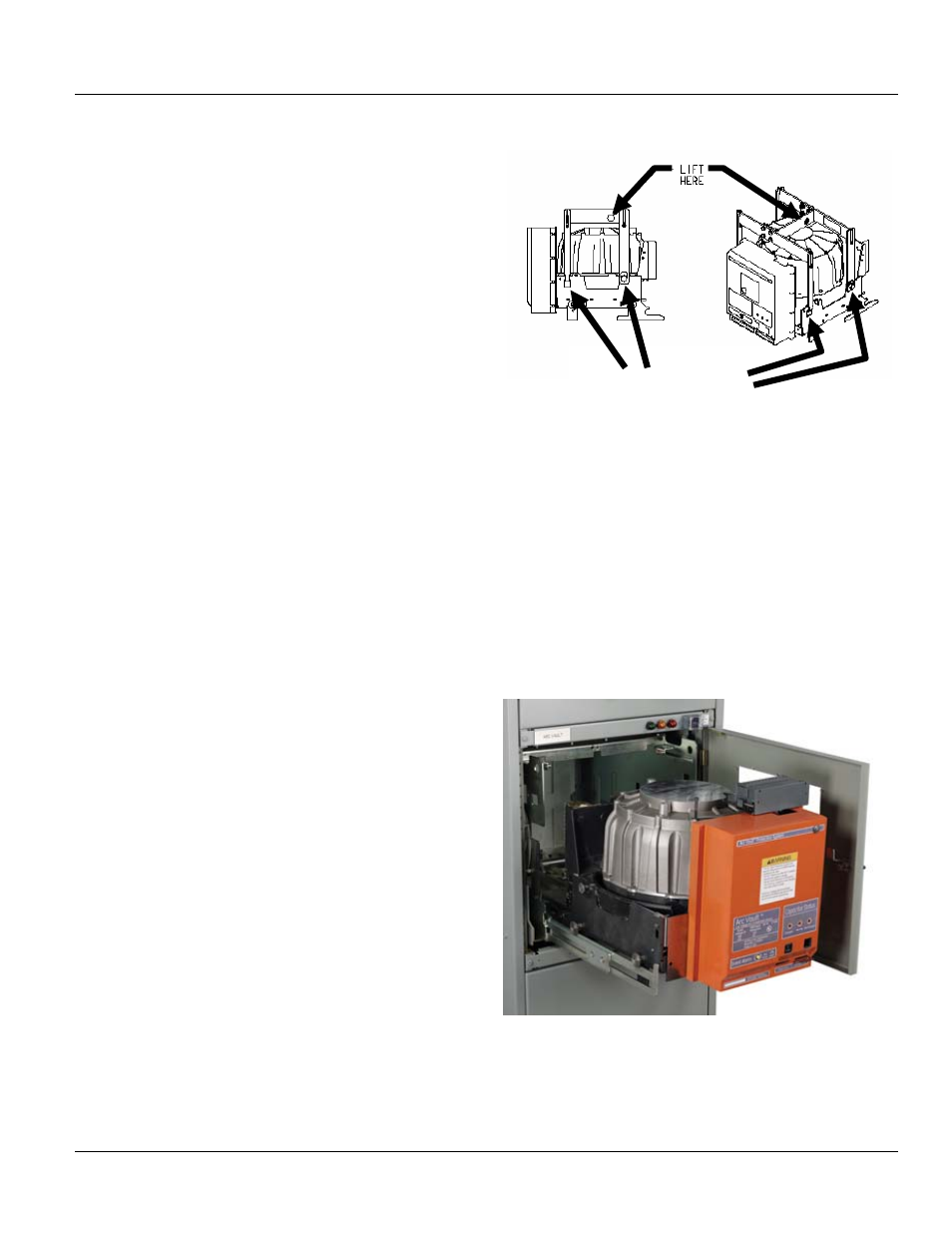

ARC VAULT LIFTING MECHANISM PT # GAVLD1

Figure 11-1 Lifting mechanism connection points

Position and connect the lifting mechanism to the Arc Vault

device as shown in Figure 11-1. There are two square

openings on the frame sides and two top hat shaped pins

connected to the frame. Slide out the rails located in the

cassette. With the lifting mechanism in place you can now

attach to the lifting hole to lift and position the device on

the rails using the four top hat shaped rolling pins. Be

careful that the pins are located properly on the rails before

disconnecting the lifting mechanism. Device can now be

rolled into the cassette to the disconnected position. Side

rails can be pushed into the cassette until seated.

Figure 11-2 Arc Vault device with extended rails and

roller pins in place

Connection Points