Warning, Caution, Notice – GE Industrial Solutions Arc Vault Protection System User Manual

Page 11

DEH-41483 Rev. 3

Arc Vault™ Protection System

Receiving, Handling and Storage

© 2011 General Electric All Rights Reserved

3

Example: Switchgear Section Weight = 2,000 pounds. The

crane and the four lift cables must have a minimum load

lifting capacity of 4,000 pounds.

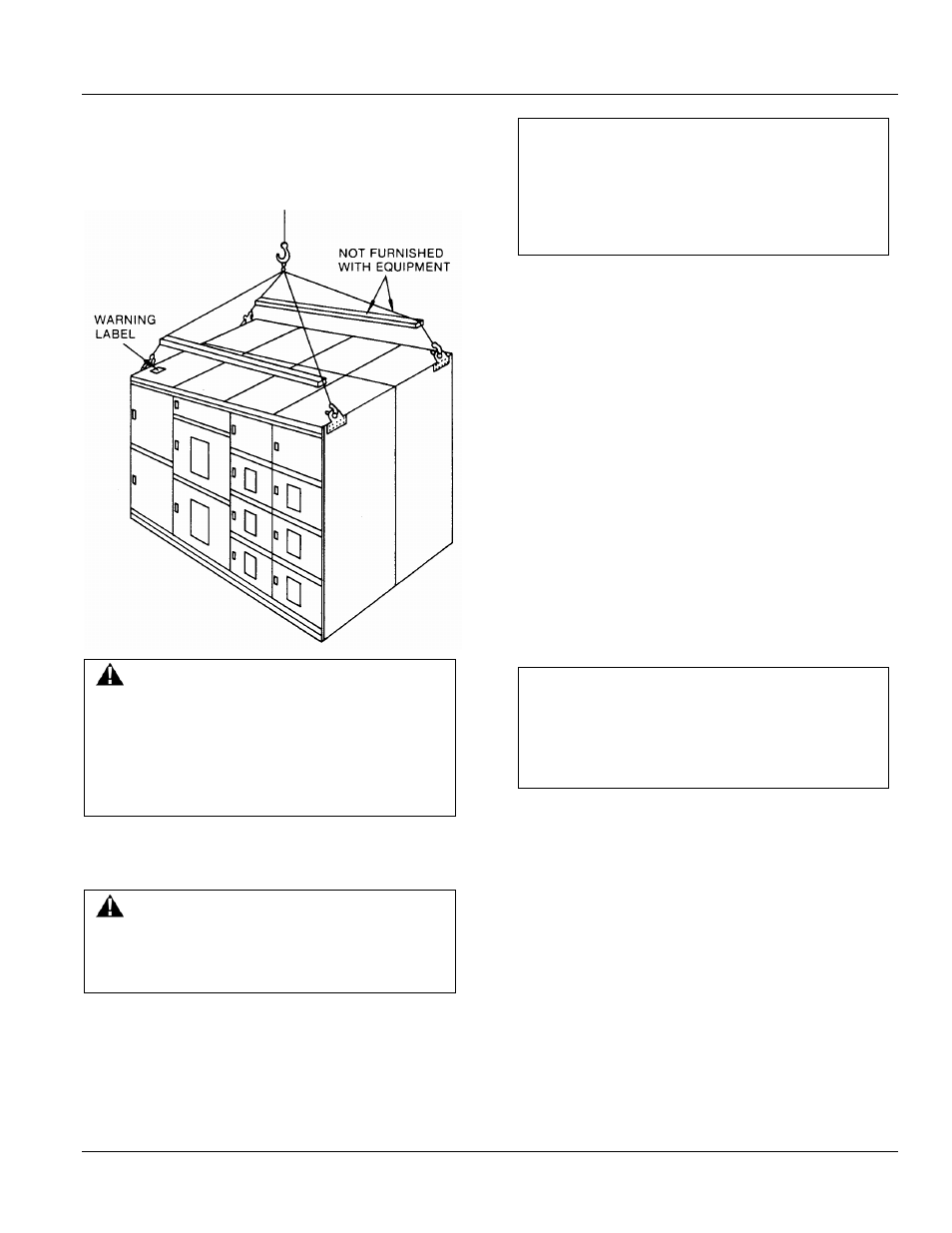

Figure 2-2 Recommended lifting method

WARNING

The angle between the cables and the top of the

equipment must be at least 45 degrees. If this is not

possible because of lack of headspace, spreader bars

must be used. Also, lift cables with greater load

capability may be necessary, depending upon the

angle between the cables and the crane hook.

Connect a cable from the crane to the four lifting plates

located on the top-front and rear of the indoor

switchgear. See Figure 2-2.

WARNING

Do not stand under switchgear while it is being

moved. Serious injury may occur if the cables or

lifting device fail.

CAUTION

Gently lower the switchgear section onto the level site

location. If the switchgear is roughly handled or

jarred, it is possible to damage or misalign internal

components.

Rollers

If crane facilities are not available, the equipment may be

moved into position by means of construction rollers

placed under the shipping skids. The switchgear may be

raised enough for the placement of rollers by means of a

fork lift or jack.

There should never be less than four rollers under the

equipment unless the line-up is less than five feet long.

Use one roller for each 18 inches of equipment length.

Forklifts

When using a forklift to raise the line-up to position rollers

underneath, proceed as follows:

1. Expand forklift tines to their maximum (widest)

extension.

2. Carefully insert tines of forklift below one side of the

switchgear line-up at the approximate center of the

panel as shown in Figure 2-3.

NOTICE

Do not attempt to lift or move the equipment with a

forklift positioned in the front or rear of the

equipment. Equipment may tip over and get

damaged.

1. Raise equipment and position one roller under the

skids close to the raised end of the line-up.

2. Carefully lower the gear until it rests on the roller as

shown in Figure 2-4.

3. Repeat the lifting process at the other end and place

the appropriate number of rollers under the skids

spacing them evenly across the width of the line-up.