Caution – GE Industrial Solutions Arc Vault Protection System User Manual

Page 13

DEH-41483 Rev. 3

Arc Vault™ Protection System

Receiving, Handling and Storage

© 2011 General Electric All Rights Reserved

5

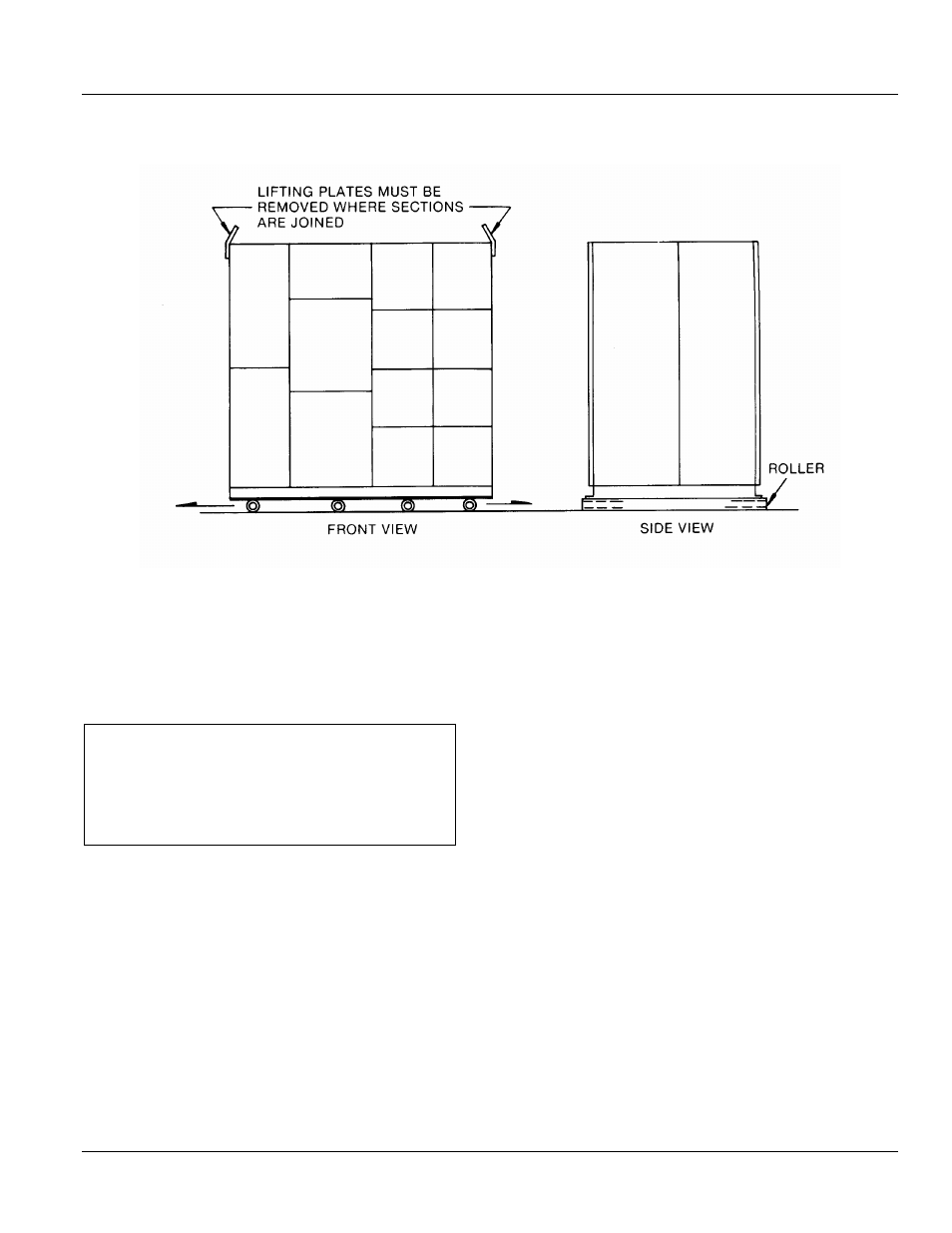

Figure 2-5 Method of rolling equipment into place

Jacks

Jacks may be used in place of forklifts to raise and lower

switchgear. Jacks

1. Place a jack under the front and rear corners of one

end of the line-up.

CAUTION

Do not place jacks in any other location other than

the front and rear corners of the switchgear. Doing so

may result in serious damage to the switchgear

equipment.

2. Raise the switchgear evenly and just enough to

position a roller beneath the equipment. Gently lower

the switchgear onto the roller. Repeat the procedure

at the opposite end of the switchgear, raising the

gear far enough to place the appropriate number of

rollers under the skids, spacing then evenly across

the width of the line up. Gently lower the gear onto

the rollers.

3. While carefully pushing the switchgear to its final site

position, the rollers that are freed from the rear of the

switchgear are then repositioned at the forward end.

This procedure should be continued until the

switchgear is in its final location.

4. When the switchgear is in its final position, remove all

lag bolts holding the shipping skids to the switchgear

line-up.

5. Place one jack at each corner, front and rear, of the

switchgear. Carefully raise the line-up evenly and

remove the rollers and the shipping skids. Evenly

lower the line-up to the floor and remove the jacks.

STORAGE

Switchgear

If it is necessary to store the switchgear equipment for

any length of time, the following precautions should be

taken to prevent corrosion or deterioration.

1. Remove protective covering. Check thoroughly for

damage.

2. Store in a clean, dry, rodent-free location with

moderate temperature and provide protective

coverings to prevent dirt, water, or other foreign

substances from entering the switchgear.