Caution – GE Industrial Solutions Arc Vault Protection System User Manual

Page 29

DEH-41483 Rev. 3

Arc Vault™ Protection System

Equipment

Installation

© 2011 General Electric All Rights Reserved

21

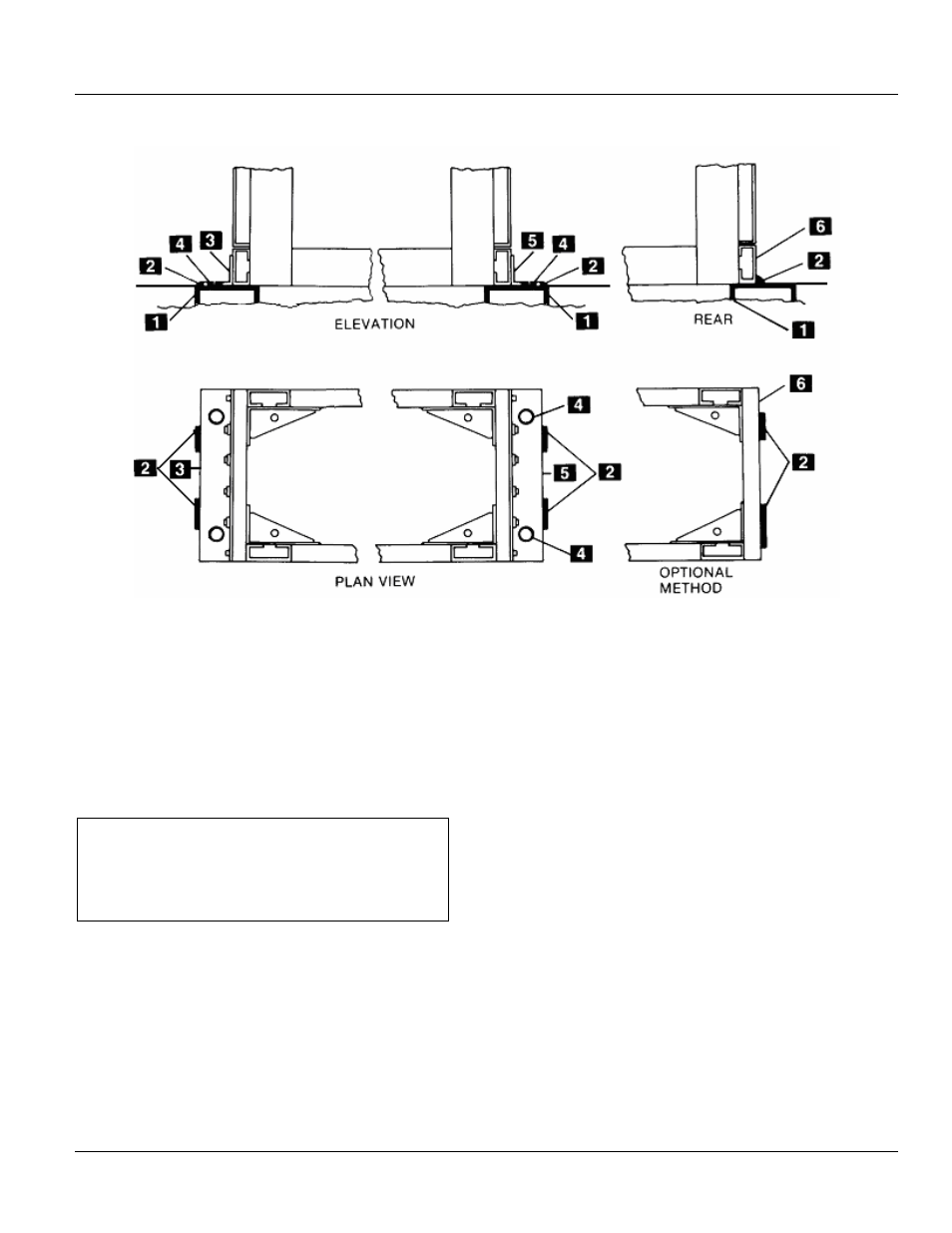

Figure 4-7 Indoor equipment weld anchoring

1. Channel sill

2. 3/16-inch fillet weld

3. Front sill angle

4. Plug weld in anchor bolt hole

5. Rear sill angle

6. Rear width post

The four anchor bolts should be tightened with a torque of

45-55 ft-lbs.

CAUTION

If the equipment is to be subjected to operational or

environmental (seismic) shock loading, the factory

must be consulted for anchoring recommendations.

Control Wire Connections

For external control wiring, refer to Figure 4-3 for

switchgear cable area dimensions, and connect the control

wires to the switchgear section as follows.

1. When control conduits enter the switchgear from

below, they should not extend more than one inch

above the floor. The control wires may be pulled

through the conduits before or after the switchgear is

installed.

2. Route the control wires from the conduits through the

wiring trough at the side of the cable compartment,

shown in Figure 4-3. Connect the cables to the terminal

blocks in accordance with the connection diagrams for

the equipment.

3. If the control conduits enter from above, drill the top

cover within the available space indicated. See Figure

4-3. Control wires should be routed to the wiring trough

and connected to the terminal blocks as described

previously.

Power Cable Connections

Connect the main cables to the main lugs. Before any main

cable connections are made, the cables should be identified

to indicate their phase relationship with the equipment.

Adequate electrical and mechanical clearances must be

provided between conduit, cables, and bus.