Closing down, Maintenance – M&C TechGroup SP2500-H_C_I_BB_F Operator's manual User Manual

Page 20

20

Gas sampling and gas conditioning technology

2-1.1.5-ME

14

CLOSING DOWN

Prior to closing down, i.e. switching off the heating, the probe should be flushed with inter gas or air in

order to prevent the condensation of aggressive components from the process gas.

15

MAINTENANCE

Prior to carrying out maintenance and repairs, the system and process-specific safety measures must

be observed.

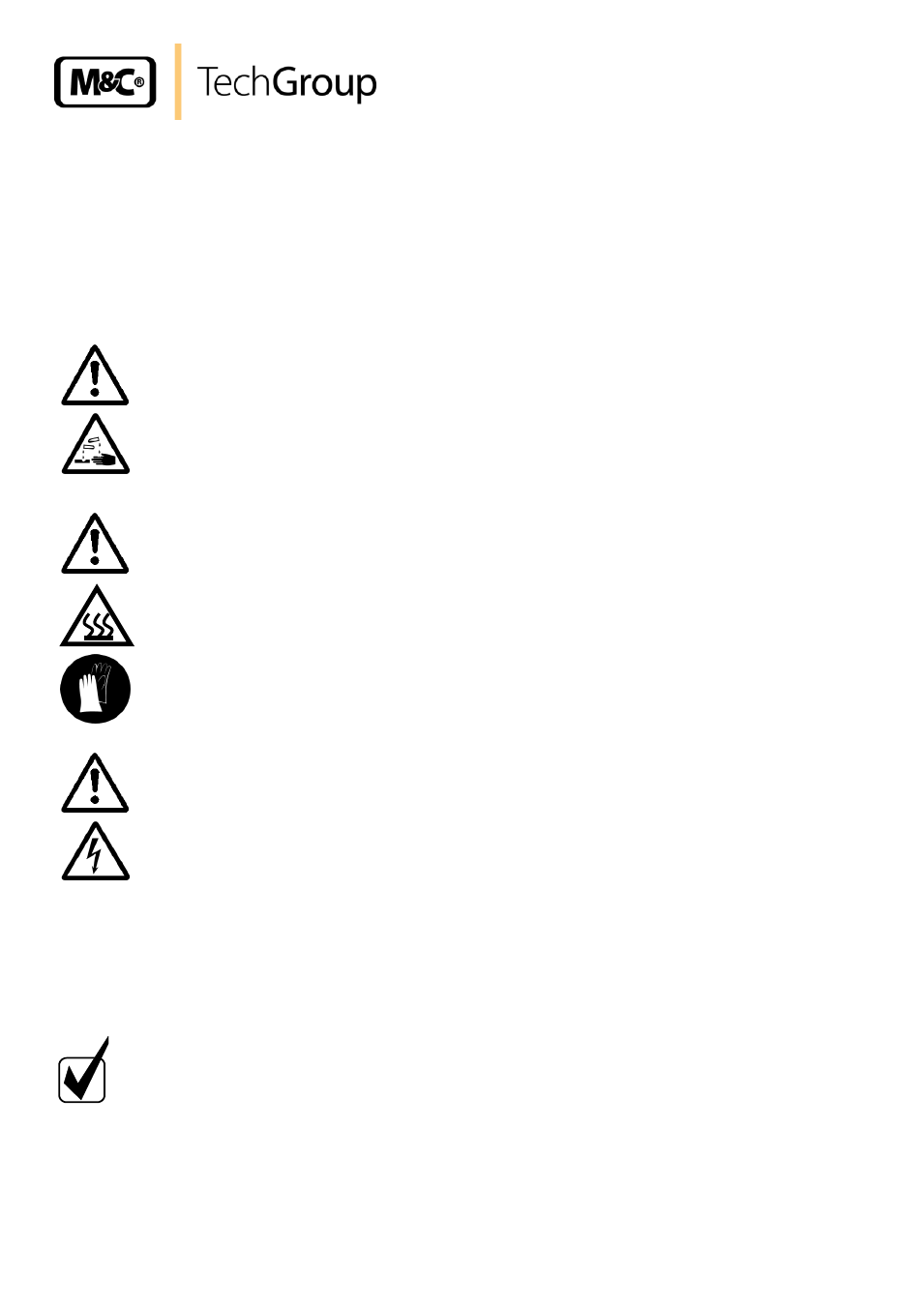

W A R N I N G !

Beware of aggressive condensate. Wear safety goggles and

appropriate protective clothing!

W A R N I N G !

Caution: Do not touch the probe surface when in use. The high

surface temperatures that prevail are liable to cause burns.

Protective gloves must be worn and the probe must be protected to

prevent unauthorised access!

W A R N I N G !

Prior to carrying out maintenance on electrical components, the

power supply must be disconnected in all poles. This applies

similarly to any connected alarm and control circuits!

Maintenance intervals cannot be recommended. These must be determined depending on the specific

application.

Maintenance of the probe is limited mainly to replacement of the filter mats and inspection of the seals

and gaskets.

N O T E !

The probe can remain mounted for maintenance or repairs.

Replacement of the process-sided sample tube can take place with the

probe head mounted.