Technical data, 8technical data – M&C TechGroup SP2500-H_C_I_BB_F Operator's manual User Manual

Page 11

11

Gas sampling and gas conditioning technology

2-1.1.5-ME

8

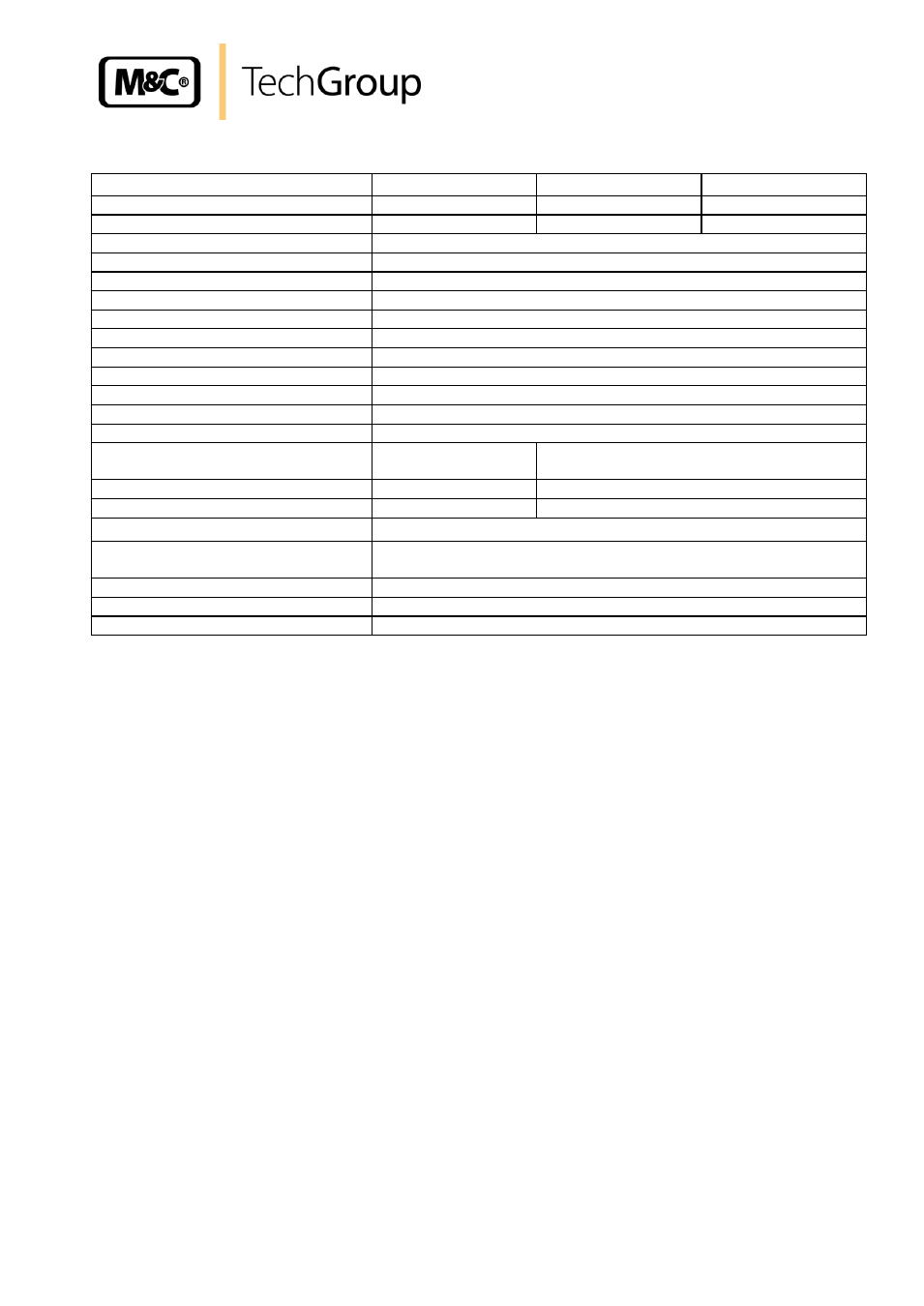

TECHNICAL DATA

Technical data SP

® series

SP2500-H

SP2500-H/C/I/BB

SP2500-H/C/I/BB/F

Article number

20 S 3510

20 S 3520

20 S 3530

Integrated backflushing

No

Via filter space

Via filter element

Weatherproof cover

Yes

Electrical connection

Terminals; max. 4 mm², 2 x PG13.5 cable gland

Degree of protection of terminal box

IP54

EN60529

Power supply

230V 50/60Hz, 800W

or

115V 60Hz, 800W

(fuse 10A)

Material of medium contacted parts

Stainless steel 1.4571, 1.4404, FPM*, Graphite**

Ambient temperature

-20°C to +60°C*** /PT100, /Fe-CuNi,/Ni-CrNi** = -20°C to +80°C

Operating temperature

0-180°C* /PT100** /Fe-CuNi** /Ni-CrNi**

Process pressure

0.4 to 6 bar abs.

Ready for operation

after 40min

Alarm contact rating

250V 3A~, 0.25A=, operating point:

ΔT 30°C** to T

nominal

Sample gas outlet connection

1/4"-NPT* internal, for tube connection Ø6, 8 or 10mm**

Calibration gas backflushing

connection

1/4“ NPTi*/C**

Backflushing: tube 8mm, calibration gas: tube

6mm

Isolating valve/I connection

1/8“ NPTi

Control air pressure range

3

– 10bar

Filter space volume

280 cm

3

Filter fineness

S-2K150= ceramic*, 2µ,/F-0,1GF150= glass fibre**, 0.1µ,/FW= glass

fibre/spun glass**

Mounting flange

DN65 PN6, Form B, 1.4571* >DN or ANSI possible**

Weight

approx. 17kg*

Electrical equipment standard

EN 61010, EN 60519-1

* Standard

** Optional

*** At high ambient temperatures, the PT100 (Art. No. 20S9025) or thermocouple Fe-CuNi or Ni-CrNi (Art. No. 20S9027 or

20S9028) option should be selected instead of the thermostat. The use of an additional electronic thermostat is

necessary (see also data sheet 4.3).

**** Option only for SP2500-H