Exchange of the valve plates, Exchange of the bellows, Cleaning – M&C TechGroup MP-F10_R Operator's manual User Manual

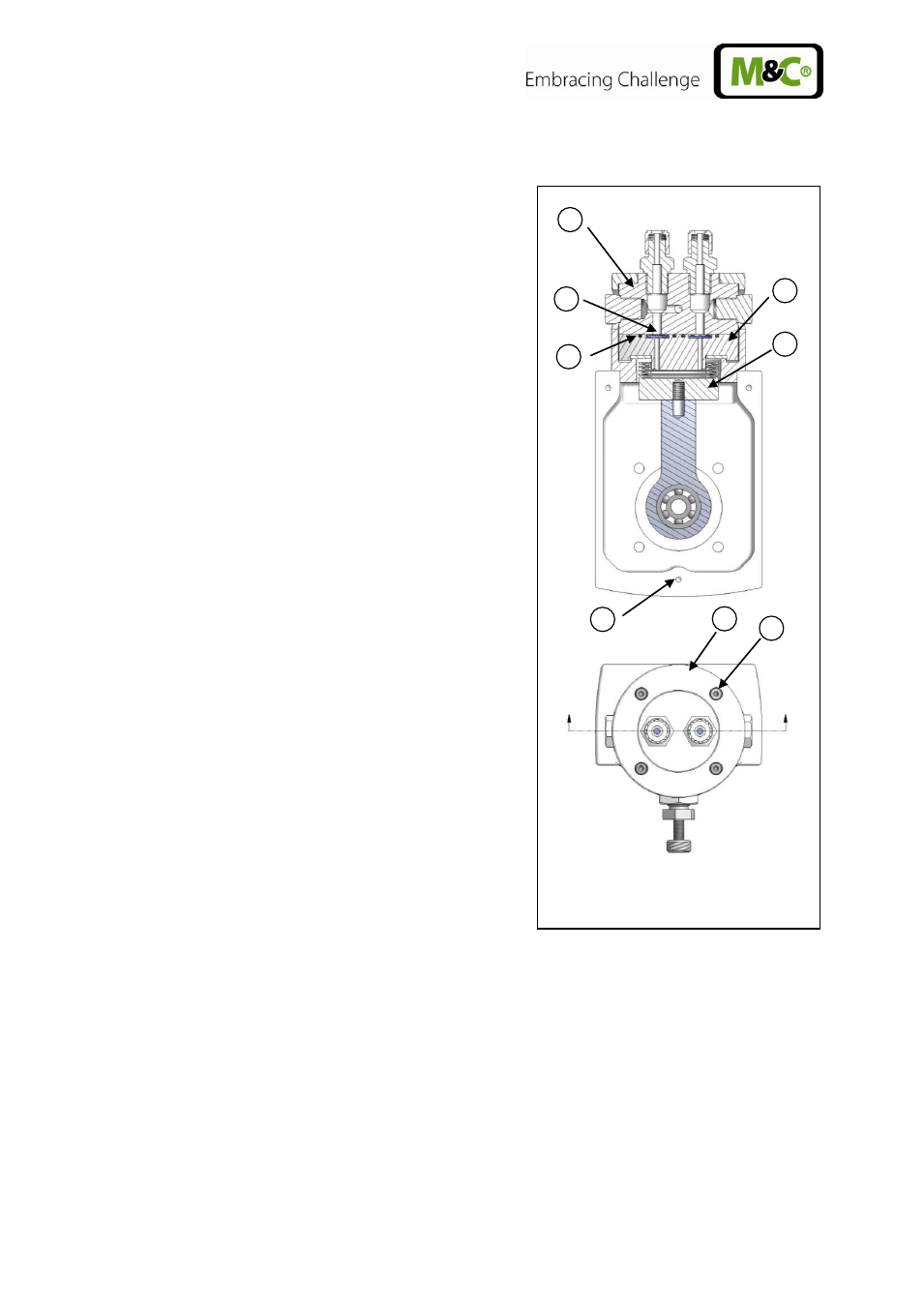

Page 16: Figure 8, Sectional drawing mp-f

16

Gas sampling and gas conditioning technology

10.1a-ME

14.1

EXCHANGE OF THE VALVE PLATES

For the exchange of the valve plates the sample gas fittings

does not have to be dismounted.

Loosen the 4 hexagon socket screws G (key 3mm)

and remove pressure ring H.

Remove upper pump head A. O-rings C and valve

plates B are freely accessible now.

The valve plates and o-rings now can be cleaned or

exchanged. Clean valve seat and pump head with an

adequate solvent (e.g. alcohol) and blow out with

compressed air.

Valve B on the pressure side is looking downwards

with the smooth side and on the suction side with the

smooth side upwards (conveying direction is marked

with an arrow on the pump head).

Remounting happens in reverse order. Attention, en-

sure the correct position of the valve plates.

14.2

EXCHANGE OF THE BELLOWS

Carry out the steps from chapter 14.1 and remove

valves and o-rings.

Unscrew lid of the crankcase. For this loosen the 3

hexagon socket screws F (key 3mm).

Remove lower pump head D. If it is stuck a borehole in

the valve seat can be closed with a finger and pres-

sure air be blown into the other one.

Unscrew the bellows E from the connection rod. Pay

attention to possibly present spacers. Leave these on

the threaded pin.

Screw new bellows hand tight on the connection rod.

Assembly happens in reverse order. Attention, ensure

the correct position of the valve plates!

Figure 7 Sectional drawing MP-F..

14.3

CLEANING

When changing valve plates and bellows, inspect all parts for dirt before assembling the pump

head and clean them if necessary.

Only use adequate solvents (e.g. alcohol) that plastic parts (PTFE, PFA, FEP) do not corrode.

If compressed air is available, blow out the parts.

G

F

H

D

E

A

C

B