Introduction, Application, Figure 1 – M&C TechGroup ECS Operator's manual User Manual

Page 8: Example of application of ec/ecs

8

Gas sampling and gas conditioning technology

3-4.1-ME

6

INTRODUCTION

The patented M&C EC/ECS gas cooler unit is always to be installed in situations where there is

interference from moisture in the gas to be measured.

Reduction of the gas temperature inside the cooler to a stable and very low dew point effects a

condensing-out of the sample gas.

7

APPLICATION

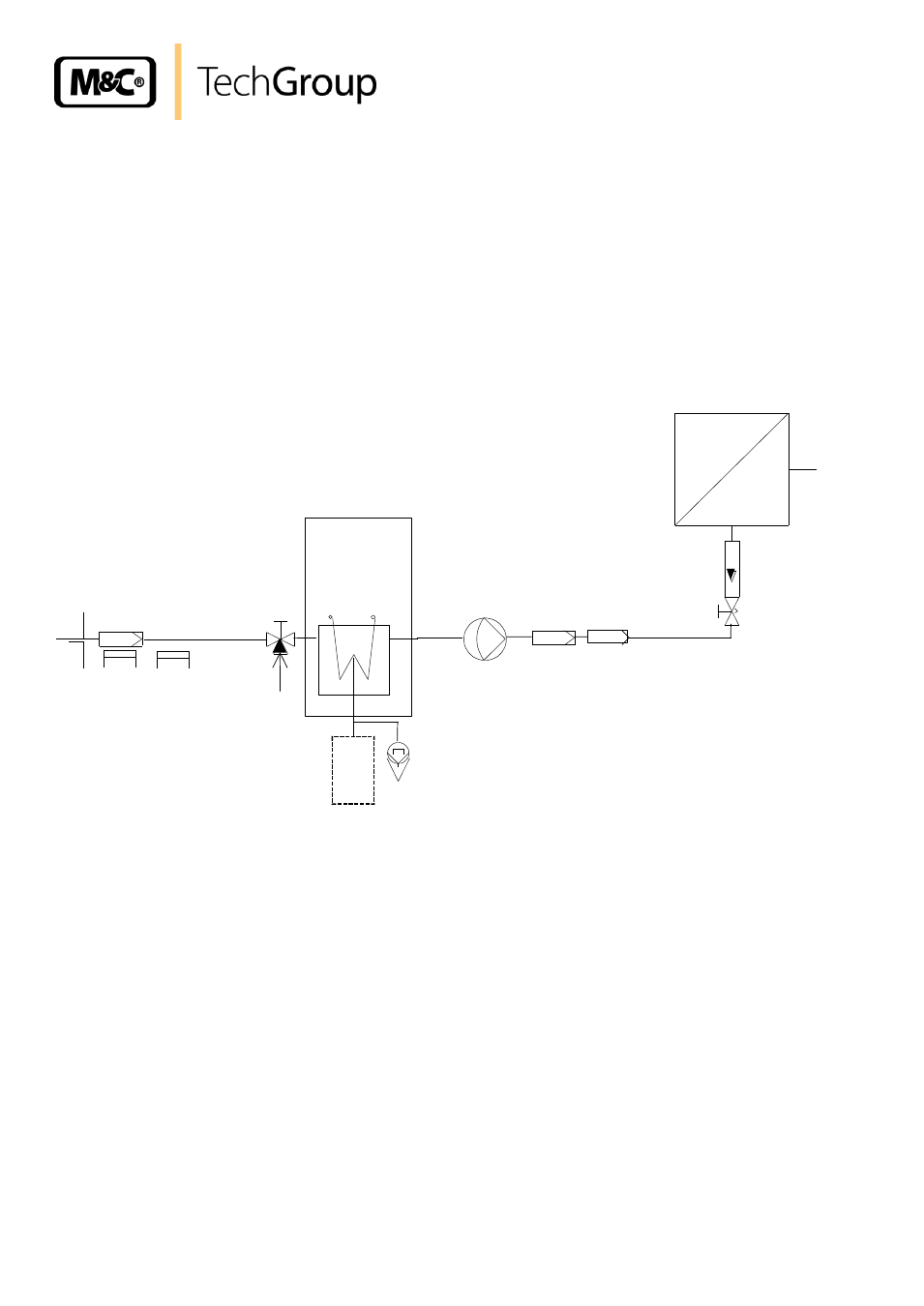

Figure 1 shows a typical example of an application for installation of an EC/ECS gas cooler unit.

Sample gas

in

+5°C

EC

Collecting vessel

Check-

gas in

Filter sample probe SP...

3-way ball valve

Super-fine filter FP...

Heated sample line

Peristaltic pump

Aerosol filter CLF

EC/ECS cooler

Membrane pump

Flow meter FM 10

Analyser

Figure 1 Example of application of EC/ECS

The gas to be measured is extracted with a gas sample pump via a gas sample probe and a

heated sample line and cooled down in the gas cooler EC/ECS to a dew point of +5°C. The

emerging condensate is removed by a peristaltic pump or a collecting vessel . The super-fine filter

located afterwards removes solid particles. For increased operating safety of the entire system we

recommend installing a super-fine filter with a liquid alarm sensor. If required an aerosol filter

can be installed in front of the flow meter . The gas thus treated can now be passed into the

analyser . For calibration of the analyser a ball-valve is existing.