Trouble shooting, 17 trouble shooting – M&C TechGroup ECS Operator's manual User Manual

Page 23

23

Gas sampling and gas conditioning technology

3-4.1-ME

17

TROUBLE SHOOTING

Troubleshooting is made much easier by the LED function display.

The following table shows possible reasons for error and how to correct them (not applicable for the

running-up phase of the cooler).

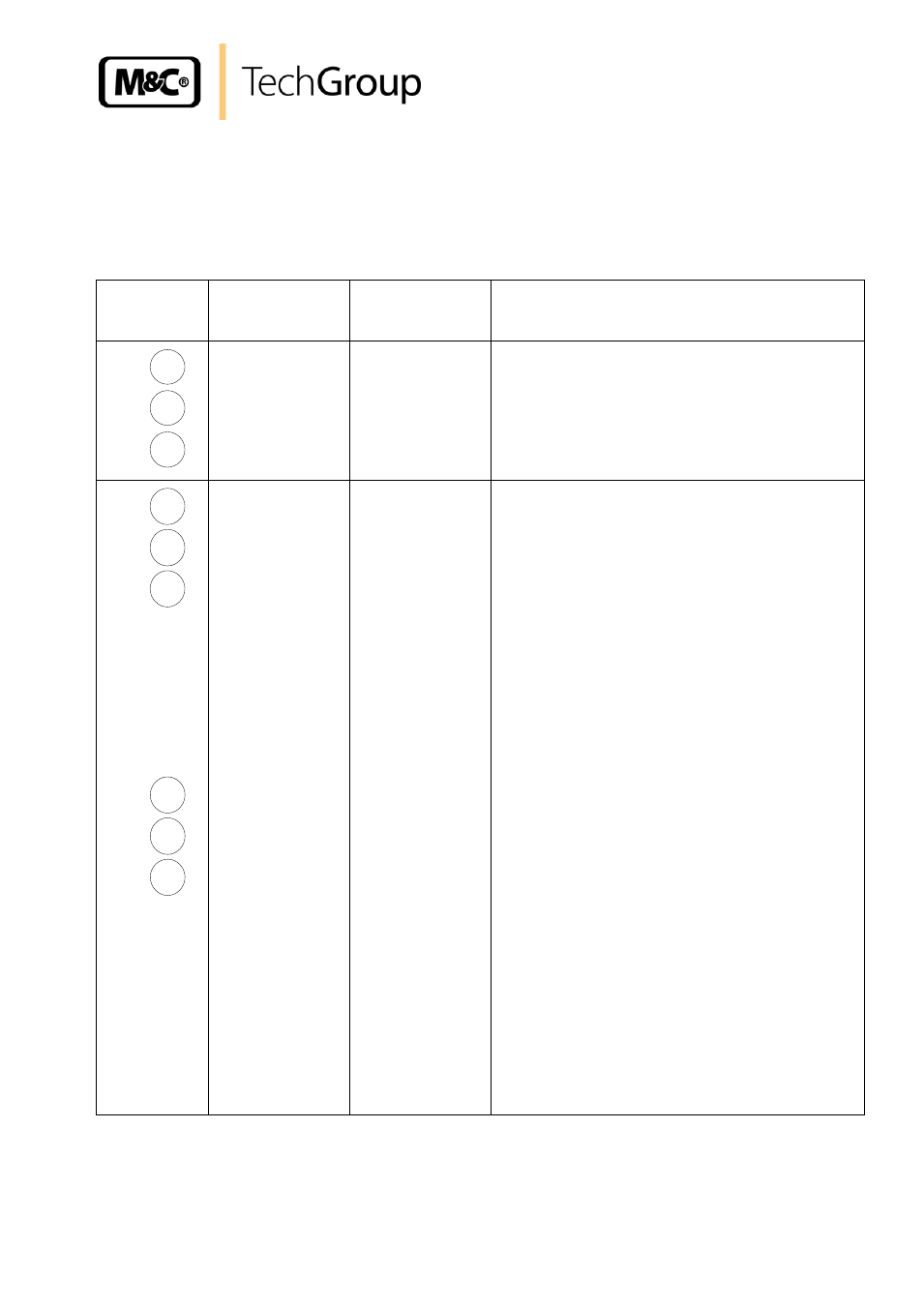

LED display Function error

and status

alarm

Probable cause

Checking / Correction

°C >

ON

°C <

Equipment

does not cool;

No mains power;

Check the mains voltage 230V (115V) at pins 18

and 19 of the EC automatic control electronics;

If mains voltage OK:

replace defective EC automatic control board.

°C >

ON

°C <

red

pink

Equipment does

not cool or the

cooling is

insufficient;

Cooling compres-

sor is not running;

Check that the plugs are firmly seated in the sockets

for power connection to the compressor;

If OK:

Measure the voltage 230V/115V for the compressor

at the EC automatic control board at pins 21 and 22.

If not OK:

Replace the defective EC automatic control board;

If OK:

Does the red LED D3 on the EC automatic control

board lights up for more than one second?

(A blocked unit will be switched off by the motor

breaker switch);

If yes:

Replace the starting condenser;

If compressor does not run:

Send cooler in for repair.

°C >

ON

°C <

red

pink

See above

Cooling compres-

sor runs; over-loa-

ding of the cooler

unit;

Check:

- Is the maximum of 250 l/h of gas flowing?

- Is the ambient temperature max. +45°C?

- Are the air suction filters dirty?

- Are the fans working?

- Are the condenser fins contaminated?

If OK:

Temperature at the EC automatic control board

(18.2);

If the temperature is < 8°C (< 0,8V) for a nominal

set temperature of 5°C:

Replace EC automatic control board;

If temperature > 8°C (>0,8V):

Check PT100 temperature sensor (19.);

If not OK:

Replace sensor;

If sensor and electronics OK:

Send cooler in for repair.