Technical data – M&C TechGroup BA-C Operator's manual User Manual

Page 8

8

Gas sampling and gas conditioning technology

10-1.1.1-ME

Gas conditioning section:

The second cleaning stage are two mol sieve columns removing CO

2

and moisture (Fl2 and FI3)

being switched and purged resp. regenerated cyclical.

The inlet pressure is 70 - 145 psig. The manometer P1 on the front plate of the BA-C enables the

optical control of the inlet pressure.

The cleaned air is available at the outlet 2

. Here a connector G ¼“ i provided by customer can be

mounted.

If the inlet pressure drops to a value below 73 psi or the catalyst temperature falls below 914°F the

gas flow is switched off.

8

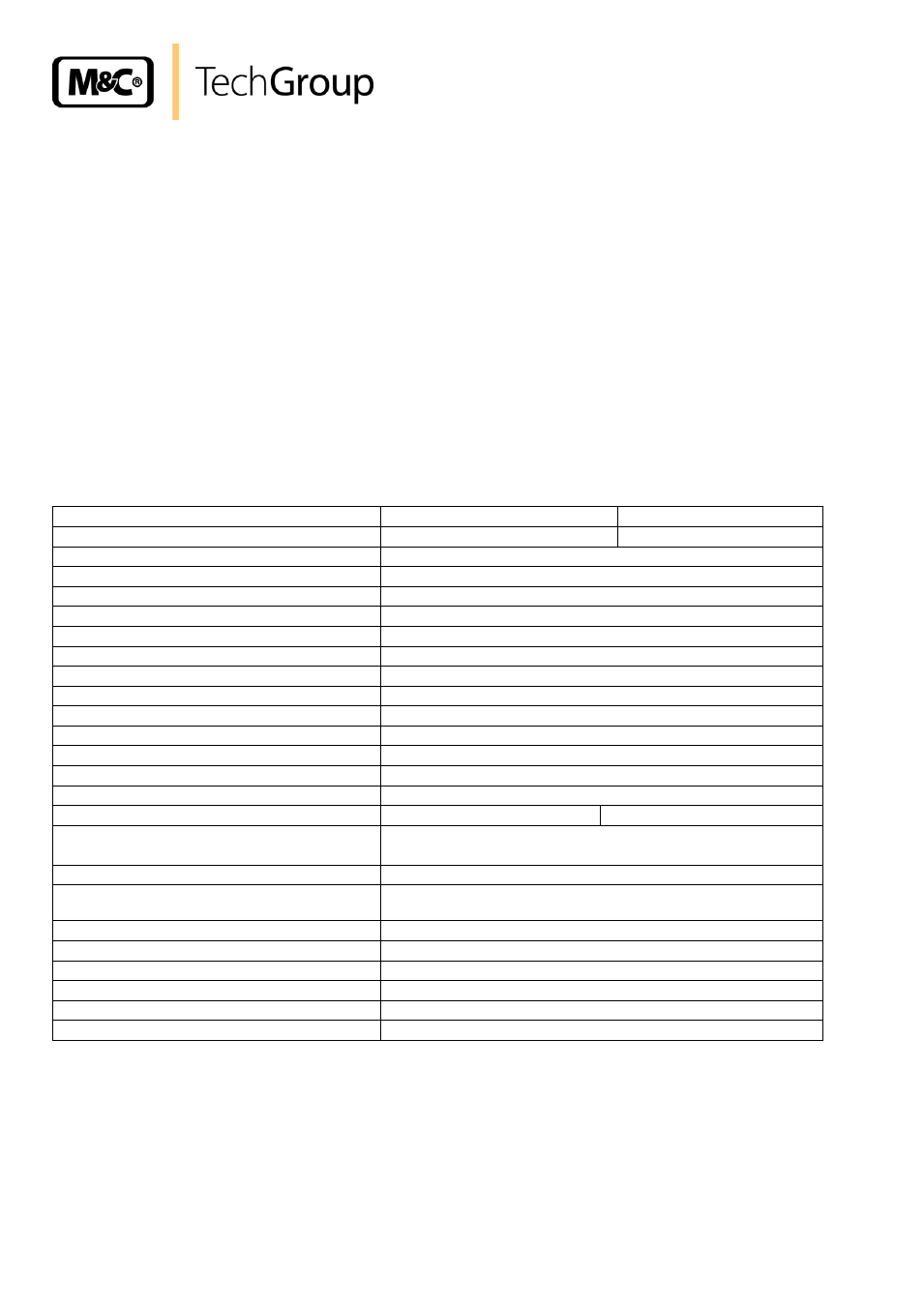

TECHNICAL DATA

Combustion Air Conditioning Unit

Type BA-C 230V

Type BA-C 115V

Part No.:

60 A 2000

60 A 2200

Inlet pressure

Instr. air 73 psi up to 145 psi

Flow rate air

maximum 15 Nl/min

Ambient temperature

+41°C to +104°F

Ready for operation

approx. 15 min.

Catalyst

Platinum/Paladium on Al

2

O

3

-Support

Temperature of catalyst

932°F

Contamination of catalyst

Halogene, silicon, lead, phosphoric substances

Adsorber

Molecular sieve

Purity of air

< 2 ppm CO

2

Storage temperature

-13°C to +149°C

Relative humidity

< 75 % avoid condensation

Gas connection „Inlet‟

G1/4“i

Gas connection „Outlet‟

G1/4“i

Power supply / Power consumption

230V 48-62 Hz 560VA

115V 48-62 Hz 150VA

Electrical connection

Mains cable 3x 1,5² 3 m length with cable end contact

Status cable 2x 0,75² 3m length with cable end contact

Electrical protection

1 x 4A

T

Status contact output

for pressure and temperature

1 NO contact - potential free, max . 24V, 1A

Protection

IP 20

(EN 60529)

Dimensions

19" housing 6 U (HE), depth 375 mm

Weight

24,5 kg

Colour of front plate

Ral 7035

Noise

Approx. 70db(A) cyclic 5min

Electrical equipment standard

EN 60204-1, EN 57721