Introduction, Function, Figure 1 – M&C TechGroup BA-C Operator's manual User Manual

Page 7: Function diagram of ba-c air conditioning units, 6introduction, 7function

7

Gas sampling and gas conditioning technology

10-1.1.1-ME

6

INTRODUCTION

The M&C BA-C air conditioning unit has been designed especially for applications where dry, cleaned

and hydrocarbon-free air is required, independent of gas cylinders.

Typical applications are hydrocarbon measurements with flame ionisation detectors (FID) and use as

a zero gas generator for the calibration of infrared (IR) analyzers or for production of dilution gas for

M&C dilution probes.

The M&C BA-C air conditioning units are compact, operator and service-

friendly 19” plug-in units for

19”-rack mounting or wall mounting.

7

FUNCTION

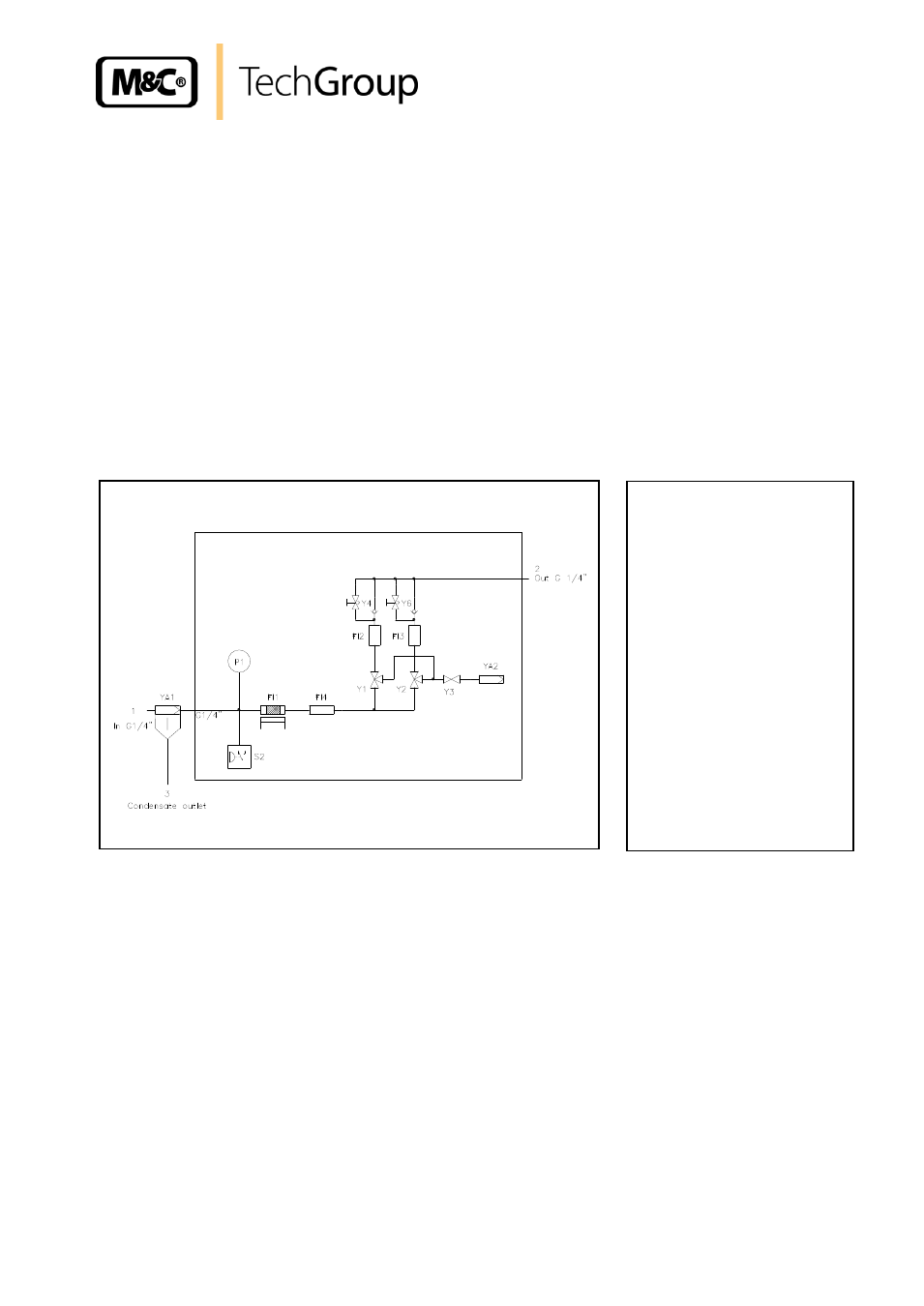

Figure 1

Function diagram of BA-C air conditioning units

The functional principle of the M&C combustion air conditioning unit is divided into two sections (see

Figure 1):

Hydrocarbon elimination section

Gas conditioning section

Hydrocarbon elimination section:

Catalytic oxidation Fl1 of hydrocarbons at a temperature of 932°F at the surface of the

platinum/palladium filling. The optimum catalyst temperature is adjusted ex works at the temperature

controller B1 of the air conditioning unit.

1 = Connection for oil-free

compressed air resp.

instrument air

2 = Outlet

3 = Condensate out

FI1 = Catalyst

FI2/3 = Adsorber

FI4 = Buffer vessel

P 1 = Manometer

S 2 = Pressure switch

Y1,2,3 = Solenoid valve

YA1 = Filter

YA2 = Pressure controller

Y4,Y6 = Needle valve