Torquemaster, Spring removal continued – Wayne-Dalton 9100 User Manual

Page 8

Tools Needed:

8

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your

local yellow pages/business listings or go to the Find a Dealer section online at www.wayne-dalton.com

Spring tube should be free to rotate in

either direction. If the counterbalance

cable is still taut and the TorqueMaster

®

spring tube is diffi cult to rotate, that is an

indication that spring tension still exists

on the left hand spring. Repeat Steps 1

and 2 for releasing spring tension on the

left hand side.

Step 4: Using a fl at tip screwdriver, pry

the counter gear and counter cover

from the right hand end bracket (Fig. 4

on previous page). Discard the counter

gear and counter cover. On double spring

applications, repeat for left hand side.

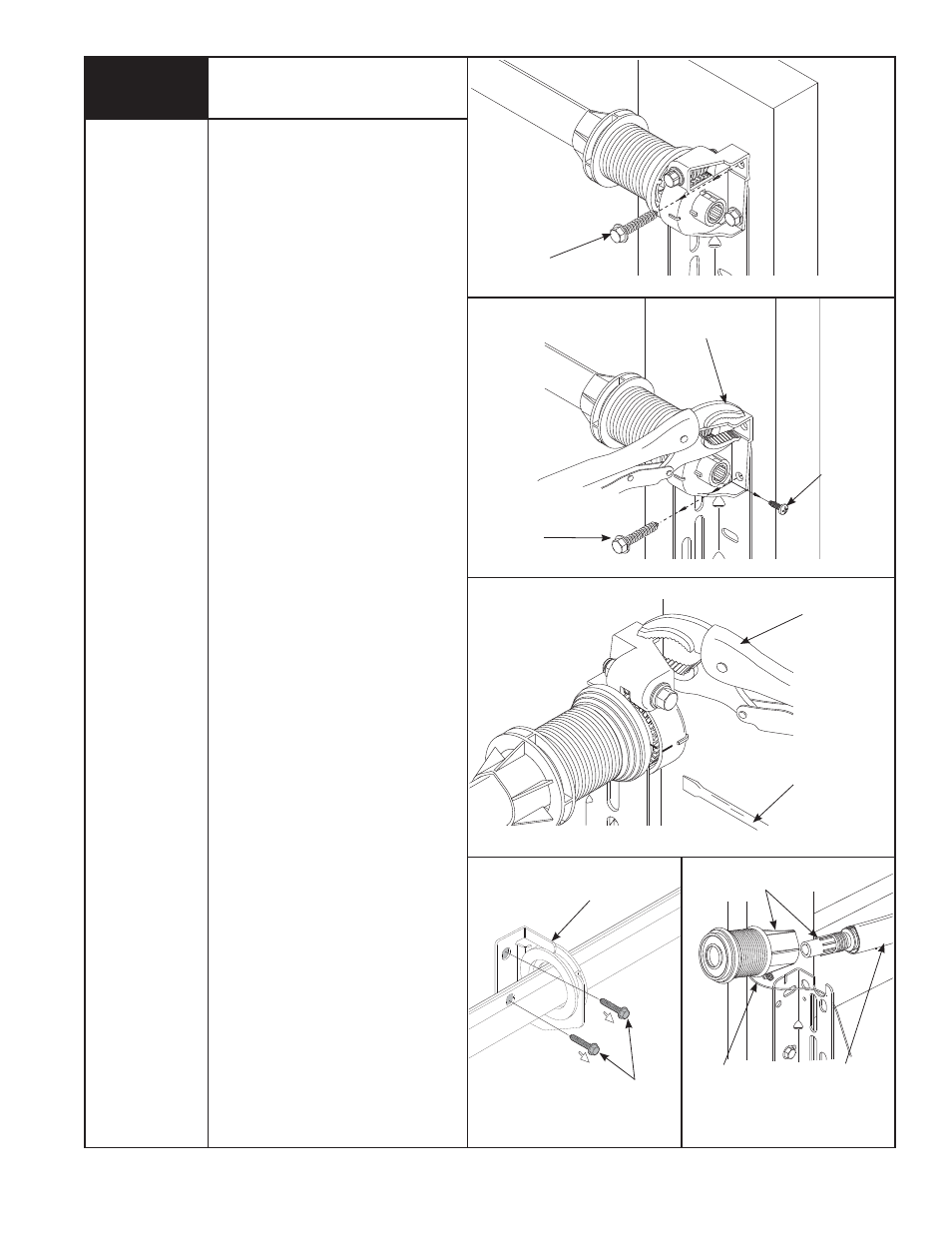

Step 5: Remove the upper 5/16” x

1-5/8” lag screw from the right hand end

bracket (Fig. 5). Attach locking pliers to

the upper portion of the end bracket and

hold the housing steady while removing

the lower 5/16” x 1-5/8” lag screw and

#10 x 1/2” phillips head screw from the

end bracket (Fig. 6).

Step 6: Holding the right hand end

bracket steady with locking pliers,

carefully pry the end bracket and drive

gear off the winding shaft using a fl at tip

screwdriver (Fig. 7).

CAUTION: THE WINDING SHAFT MAY

ROTATE WHEN REMOVING THE END

BRACKET AND DRIVE GEAR.

Step 7: Repeat Step 4 for the left hand

side. Holding the left hand end bracket

steady with locking pliers, carefully pry

the end bracket off the winding shaft

using a fl at tip screwdriver (Fig. 7).

Step 8: Remove the two (2) lag bolts

attaching the center bracket assembly to

the header board (Fig. 8).

Step 9: Lift the right hand side of the

TorqueMaster

®

spring tube and slide the

cable drum off. Realign the groove in the

winding shaft with the radial notch in the

fl agangle and drape the counterbalance

cable with drum over the fl agangle. Lift

the left hand side of the TorqueMaster

®

spring tube and slide the cable drum

and winding shaft off (Fig. 9). Drape the

counterbalance cable with drum over the

fl agangle. Lift the TorqueMaster

®

spring

assembly off the fl agangles and out of

the doorway. Unhook the counterbalance

cables from the bottom brackets and

remove all parts from the work area.

NOTE: The cable drums may be diffi cult to

remove. If so, twist the cable drum to aid

in removal.

NOTE: Continue with “P4” on page 9 after

completing this step.

Fig. 5

Fig. 6

Fig. 7

Fig. 9

REMOVE TOP

LAG SCREW

REMOVE

BOTTOM LAG

SCREW

USE LOCKING PLIERS

TO HOLD END BRACKET

REMOVE #10

PHILLIPS

HEAD SCREW

PRY END BRACKET FROM WINDING

SHAFT USING A FLAT TIP SCREW

DRIVER AND LOCKING PLIERS

HOLD THE

END BRACKET

STEADY WITH

LOCKING PLIERS

REMOVE CABLE DRUM AND

WINDING SHAFT

DRAPE CABLE

ACROSS

TOP OF

FLAGANGLE

LIFT

TORQUEMASTER

®

SPRING TUBE

OFF FLAGANGLE

TorqueMaster

®

Spring

Removal continued...

Recommended

tools from

page 5

Fig. 8

CENTER

BRACKET

ASSEMBLY

(2) 5/16” X 1-5/8”

HEX HEAD LAG

SCREWS