Inst alla tion i drive, Installation – Wayne-Dalton 9100 User Manual

Page 21

Tools Needed:

21

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your

local yellow pages/business listings or go to the Find a Dealer section online at www.wayne-dalton.com

INST

ALLA

TION

idrive

®

Installation

NOTE: See idrive

®

main installation and

owners manual for idrive

®

parts.

IMPORTANT: RIGHT AND LEFT HAND

IS ALWAYS DETERMINED FROM INSIDE

THE GARAGE LOOKING OUT.

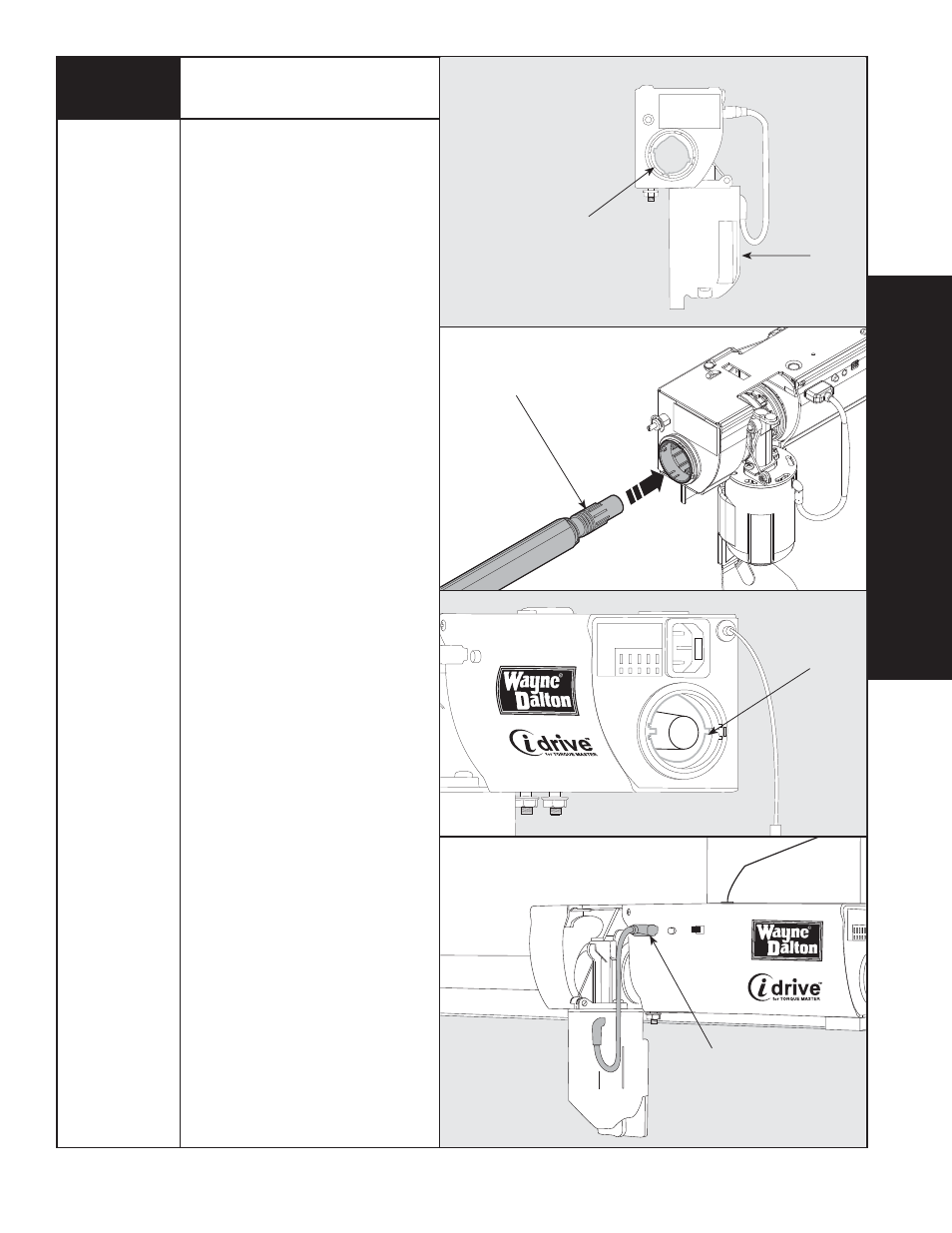

With the TorqueMaster

®

spring tube on

the floor (inside garage) in front of the

door with the labeled end to the left.

Look into the opener’s left side to

ensure the left hand bearing and the

internal (black) sleeve are aligned with

the TorqueMaster

®

spring tube profile.

IMPORTANT: HOLD OPENER BY THE

MAIN BODY. DO NOT HOLD BY THE

MOTOR.

NOTE: Opener will not slide over a

torque tube label. Attempting to slide

opener over the left end of the

TorqueMaster

®

spring tube can damage

the internal electronics.

Once aligned, slide the opener onto the

right hand end of the TorqueMaster

®

spring tube. As the right end of the

TorqueMaster

®

spring tube enters the

internal (black) sleeve, rotate the

opener back and forth slightly to help

aid alignment.

Continue sliding the opener onto the

TorqueMaster

®

spring tube. Align the

right hand bearing with the

TorqueMaster

®

spring tube and slide

the opener completely onto the

TorqueMaster

®

spring tube until the

TorqueMaster

®

spring tube exits the

opener right hand bearing.

NOTE: Do not force the opener onto the

TorqueMaster

®

spring tube if

misalignment occurs.

Continue sliding the opener to the

center of the TorqueMaster

®

spring

tube.

Plug the motor power cord into the

opener.

LEFT HAND SIDE

TORQUEMASTER

®

SPRING TUBE

AND BEARING PROFILES ALIGNED

RIGHT HAND END

OF TORQUEMASTER

®

SPRING TUBE

RIGHT HAND SIDE

TORQUEMASTER

®

SPRING TUBE AND

BEARING PROFILES

ALIGNED

PLUG-IN MOTOR

POWER CORD

MOTOR

19

Tools Needed: