Troubleshooting & repair, Caution – Lincoln Electric INVERTEC POWER WAVE 450 SVM112-B User Manual

Page 70

TROUBLESHOOTING & REPAIR

F-10

F-10

POWER WAVE 450

TROUBLESHOOTING GUIDE

Observe Safety Guidelines

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-

800-833-9353.

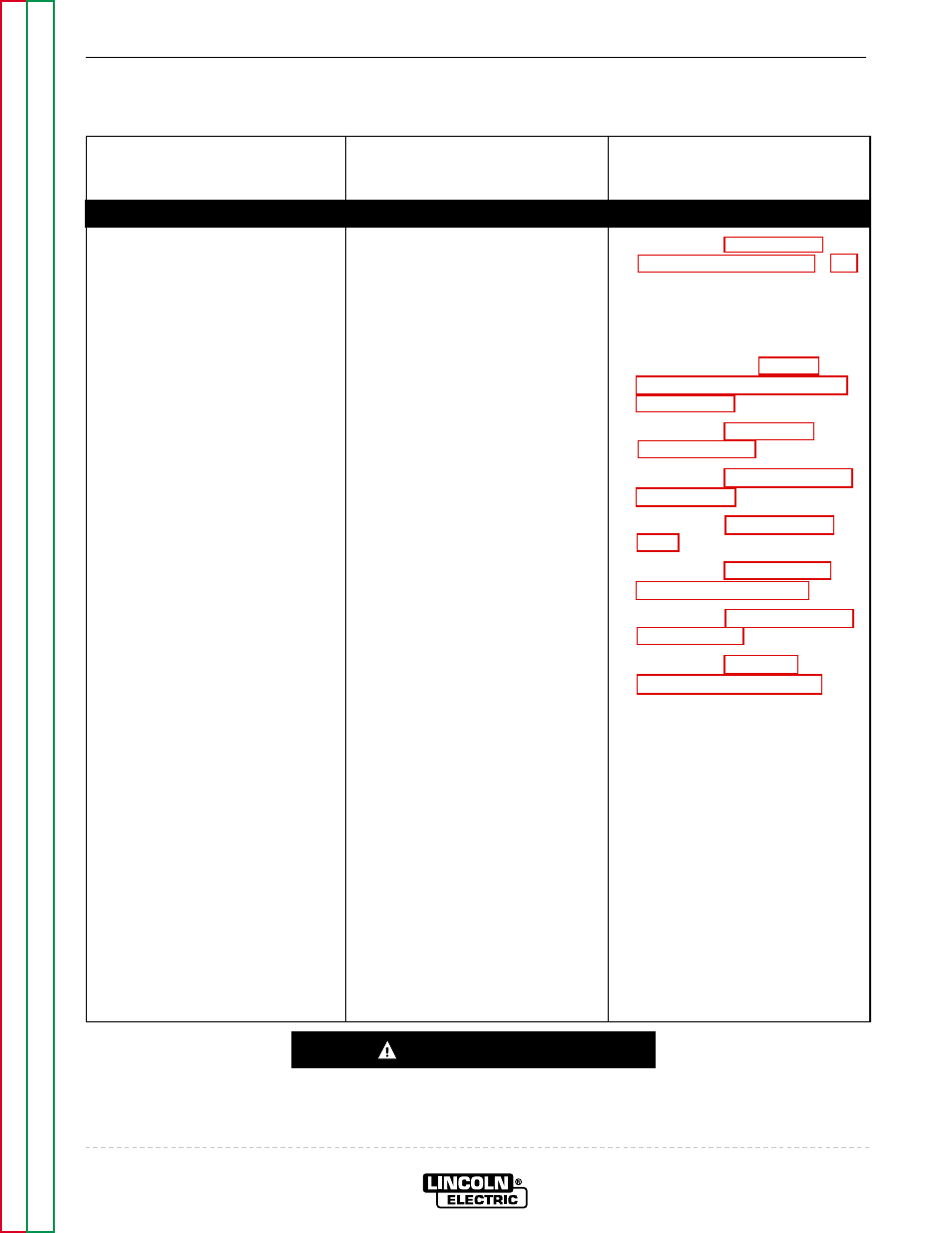

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

OUTPUT PROBLEMS

Machine has no welding output –

fans run – display is on.

1. Make sure that the machine

was powered up with a proper-

ly installed overlay. Without an

overlay installed in the Power

Wave, or an invalid overlay

installed, the machine will not

have welding output.

2. Check to see if the Limits or

Setup overlay is installed on

the front panel. These two

overlays cannot be used for

welding.

3. Check for proper input voltage

per machine nameplate.

4. Make certain the reconnect

panel is configured properly.

5. Check to see that when the

trigger is pulled on the wire

feeder the wire feeder’s voltage

display changes to indicate arc

voltage. If this does not hap-

pen, the feeder or control

cable may be faulty.

6. Check wire feeder control

cable for loose or faulty con-

nections.

7. If the machine is connected for

380VAC or higher and has not

been used for a long period of

time, the capacitors may

require “conditioning.” Let the

Power Wave run at an idle

state for 30 minutes.

Trigger Circuit Test (#1 or #2)

for the appropriate wire feeder

receptacle (amphenol).

2. If a K941-1 Remote Control Kit

is attached to the Power Wave,

then perform the K941-1

Remote Control Kit Trigger

Circuit Test.

4. Perform the Output Rectifier