Troubleshooting & repair, Warning – Lincoln Electric INVERTEC POWER WAVE 450 SVM112-B User Manual

Page 204

F-144

F-144

QUICK VOLTAGE CALIBRATION

(continued)

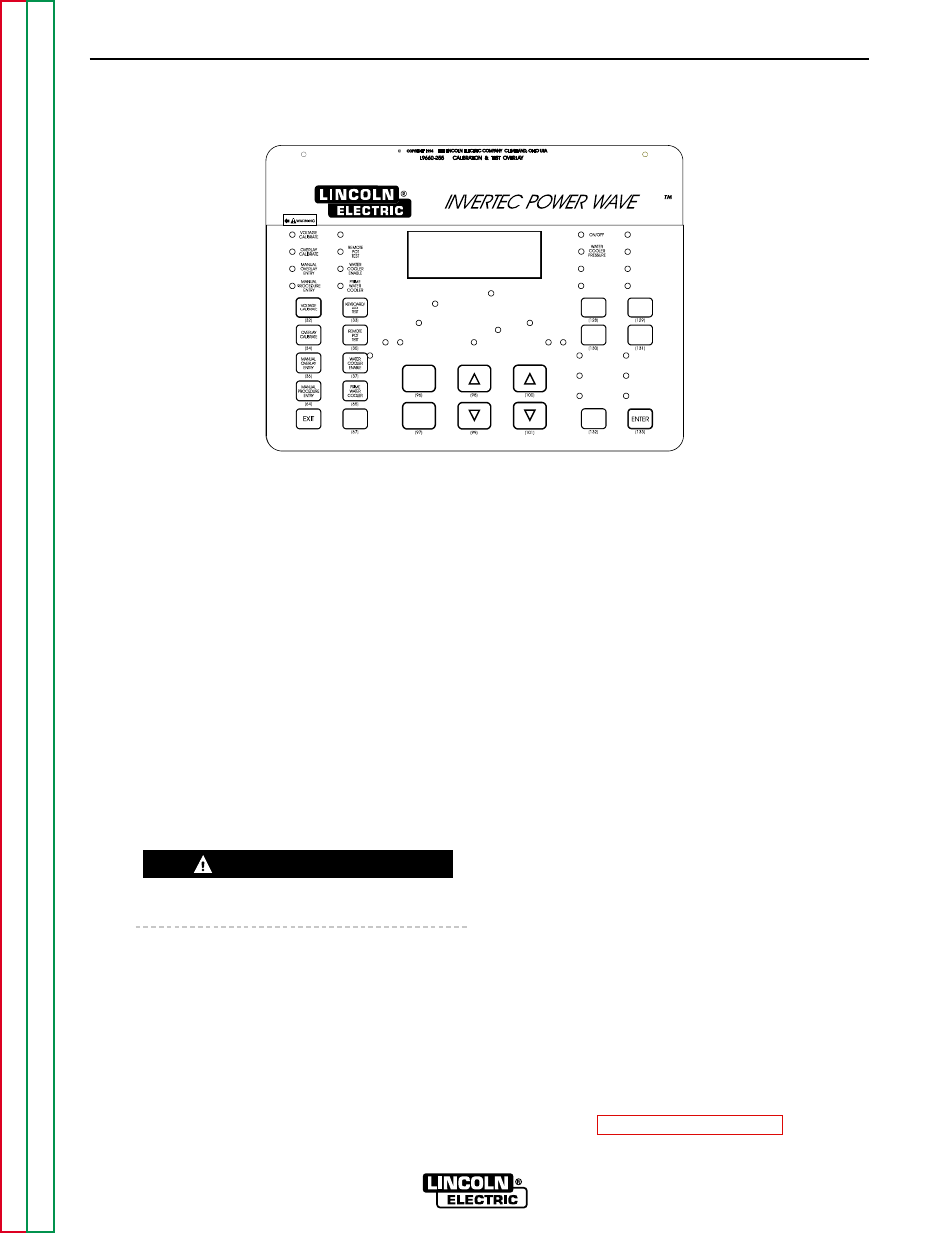

FIGURE F.54 - TEST AND CALIBRATION OVERLAY

TROUBLESHOOTING & REPAIR

PROCEDURE

1. Before changing or disturbing the display

board, power up the machine with the

L9660-255 Test and Calibration overlay in

place. See Figure F.54.

2. Press the Voltage Calibration function (32).

The machine should display the following:

VOLTAGE WIRE

+ POLARITY (+67A)

3. Press the Enter Key (133) on the lower right

side of the overlay. The machine should

display the following:

ADJUST TO 30V

CALIBRATION #=XX

NOTE: Here “XX” indicates a particular cali-

bration number for a given voltage sensing

point.

The machine’s output terminals will be electri-

cally “HOT” when the Enter Key is pressed.

4. Record the number displayed for the +67

wire and press the Enter Key (133) again.

5. Repeat the process by pressing the Voltage

Calibration function again. The next sens-

ing lead may be selected by pressing the

down Arrow Key (101). The above proce-

dure must be repeated six times to obtain

and record the calibration number for six

different voltage sensing points. These

points are the following:

+ Polarity (+67A)

+ Polarity (+67B)

- Polarity (+21A)

- Polarity (+21B)

+ Polarity

- Polarity

6.

Install the “new” replacement display

board.

7. With the L9660-255 overlay installed, apply

power to the machine. Press the Voltage

Calibration function (32). Enter the re-

corded calibration numbers for each of the

six voltage sensing points. The calibration

numbers are entered by selecting the prop-

er sensing point (lead), pressing the Enter

Key (133) and obtaining the display that

reads:

ADJUST TO 30V

CALIBRATION #=XX

The calibration number is changed using the

up/down Arrow Keys (100, 101). Press the

Enter Key when the desired number is dis-

played.

8. Repeat the process for all six sensing

points (leads).

9. Perform the Sensor Calibration Test.

POWER WAVE 450

WARNING