System design – Sanyo CHX03652 User Manual

Page 22

2-14

Design of Mini ECO-i SYSTEM

1

2

3

4

5

6

7

8

Material

O

Copper tube

Outer diameter

1/4 (6.35)

3/8 (9.52)

1/2 (12.7)

5/8 (15.88)

3/4 (19.05)

Wall thickness

1/32 (0.8)

1/32 (0.8)

1/32 (0.8)

5/128 (1.0)

over 5/128 (1.0)

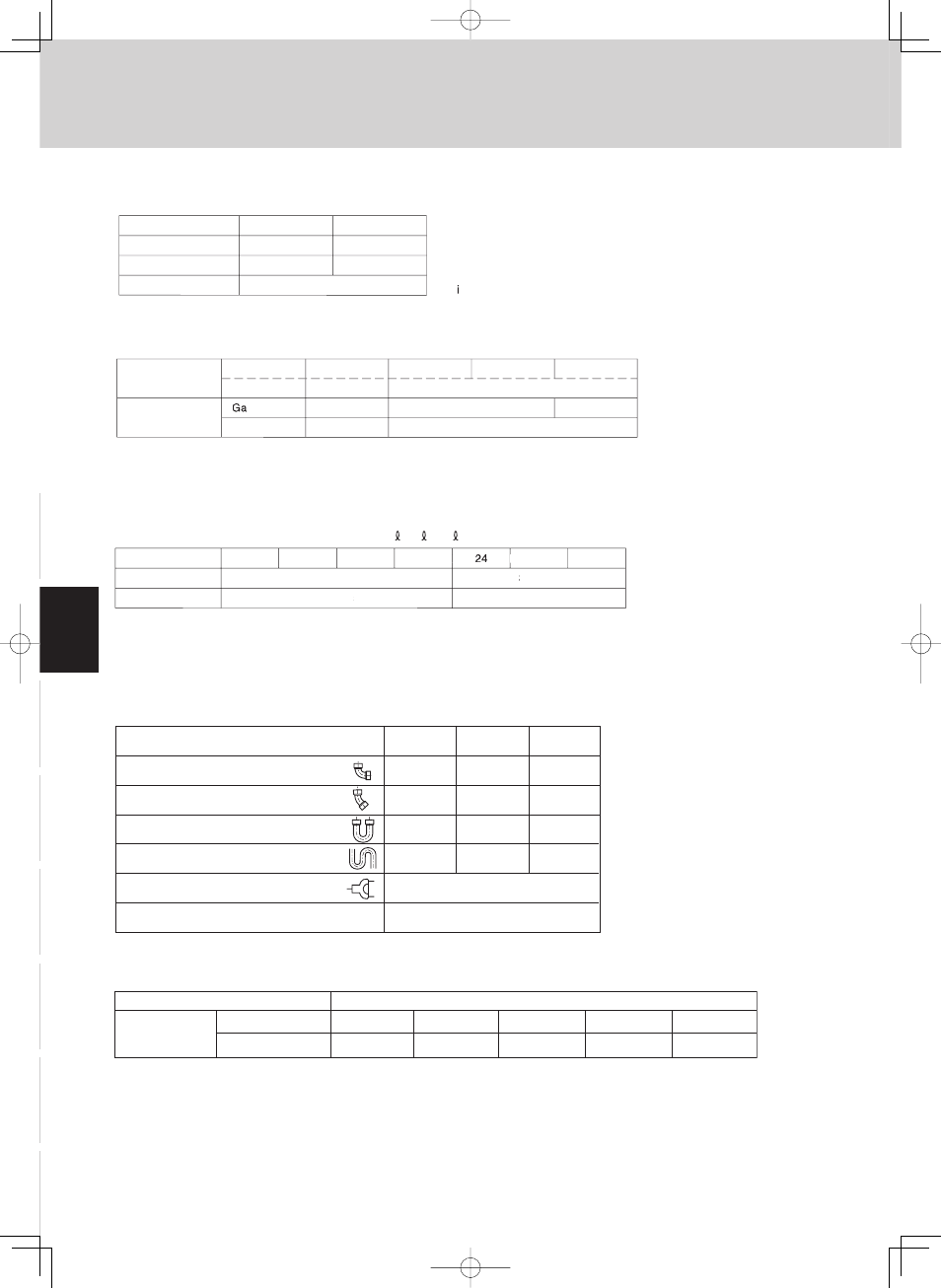

Table 2-7 Required Copper Tubing Dimensions

Unit: in. (mm)

Gas tubing size (in. (mm))

90

° elbow

45

° elbow

Trap bend

1/2" (12.7)

1

0.8

3

7.5

5/8" (15.88)

1.1

0.9

3.4

9.2

3/4" (19.05)

1.4

1

4.1

10.5

Y-branch distribution joint

Ball valve for service

U-shape tube bend (R2-3/8" – 4" (60 – 100))

Equivalent length conversion not needed.

Equivalent length conversion not needed.

2-6. Straight Equivalent Length of Joints

Design the tubing system by referring to the following table for the straight equivalent length of joints.

Table 2-6 Straight Equivalent Length of Joints

Unit: ft.

Table 2-5 Indoor Unit Tubing Connection (

1

,

2

...

n–1

)

ш

5/8

// " (

ш

15.88)

ш

1/2" (

ш

12.7)

ш

1/4" (

ш

6.3

. 5)

ш

3/8" (

ш

9.52)

7

9

12

18

36

48

Indoor unit type

Gas tubing

Liquid tubing

Unit: in. (mm)

24,200 (2.5 hp)

ш

5/

8" (ш15.88)

ш

1/2" (

ш

12.7)

ш

3/4" (ш19.05)

ш

3/8" (ш9.52)

ш

3/8" (ш9.52)

24,200 (2.5 hp)

–

38,200 (4 hp)

47,800 (5 hp)

52,900 (6 hp)

Below BTU/h

Over BTU/h

Tubing size

Total capacity

after distribution

s tubing

Liquid tubing

hp = horsepower

Unit: in. (mm)

2-5. Tubing Size

Table 2-3 Main Tubing Size (LA)

ш

3/4" (ш19.05)

6

Unit: n. (mm)

52,900 (15.5)

ш

3/8" (ш9.52)

ш

5/

8" (ш15.88)

4

38,200 (11.2)

BTU/h (kW)

System horsepower

Gas tubing

Liquid tubing

Table 2-4 Main Tubing Size After Distribution (LB, LC...)

Note: In case the total capacity of connected indoor units exceeds the total capacity of the outdoor units, select the main

tubing size for the total capacity of the outdoor units.

2. System Design