Resawing operations, Auxiliary fence – Grizzly G0696X User Manual

Page 51

-48-

g0605X1-6X1, g0696X-97X (mfg. 8/11+)

you may experience kickback during this

procedure. Stand to the side of the blade

and wear a full face shield to prevent injury

when resawing.

components Needed for Resawing:

zero Clearance insert .........................................1

ripping Blade 12" ...............................................1

Clamps ...............................................................2

shop made Auxiliary Fence ...............................1

shop made resaw Barrier .................................1

Resawing Operations

the table saw motor is pushed to its limits when

resawing. if the motor starts to bog down, slow

your feed rate. motor overloading and blade wear

can be reduced by using a ripping blade, which

are designed to clear the sawdust quickly.

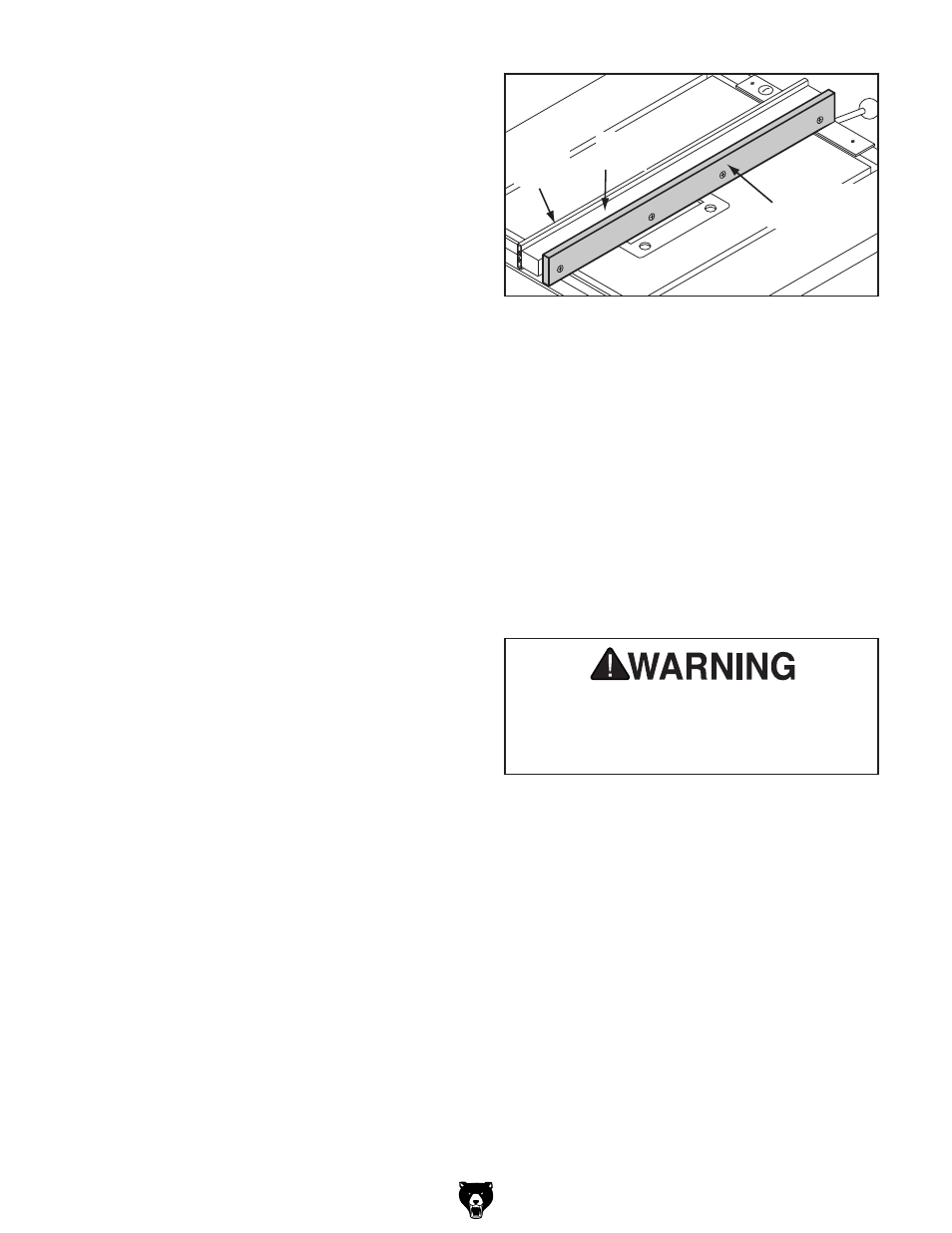

Figure 87. Auxiliary fence.

Fence

Body

Auxiliary

Fence

Fence

Facing

Auxiliary Fence

the auxiliary fence is necessary if you are

resawing a workpiece that is taller than it is wide.

it should be no less than

1

⁄

2

" shorter than the

board to be resawn.

components Needed for the Auxiliary Fence:

Wood*

3

⁄

4

" x (height) x length of Fence ............1

Flat head screws m8-1.25 x 25 (not included) .4

hex nuts m8-1.25 (included) .............................4

Flat Washers 8mm (included) ............................4

* Only use furniture-grade plywood, kiln dried

hardwood, or HDPE plastic to prevent warping.

Tools Needed for the Auxiliary Fence:

table saw ..........................................................1

Jointer and planer ....................... recommended

Clamps ............................................... 2 minimum

drill and drill Bits ................................................1

To build the auxiliary fence:

1. Cut the auxiliary fence board to size. if you

are using hardwood, cut the board oversize,

then joint and plane the board to the correct

size to make sure the board is square and

flat.

2. pull an end cap off of the standard fence,

then remove four hex nuts, flat washers, hex

bolts and one side of the fence facing from

the fence body.

3. mark the location of the four fence holes on

the top of the fence body.

4. place the auxiliary fence next to the open

side of the fence and transfer the marks from

the fence body to the auxiliary fence.

5. pre-drill and countersink four holes 1

1

⁄

4

" from

the bottom of the board.

6. thread the flat head screws through the

auxiliary fence and into the hex nuts and flat

washers inside the standard fence body, and

tighten securely, as shown in

Figure 87.

To perform resawing operations:

1. disConnECt sAW From poWEr!

2. remove the standard table insert and the

blade guard assembly.

3. install a ripping blade, install the riving knife,

lower the blade below the table, then re-

install the standard insert.

do not use the standard insert if it has lost the

zero clearance feature by modification; if so

you must install the optional model t21879.