Cutting a zero clearance insert – Grizzly G0696X User Manual

Page 42

g0605X1-6X1, g0696X-97X (mfg. 8/11+)

-39-

5. Center a board at least 2" thick and equal to

the length of the table over the rear open-

ing of the insert, then secure it with clamps

at both ends, as shown in

Figure 72. this

will provide extra support for the insert and

reduce tear out when cutting.

6. set the blade angle at 0°.

Suggestion: To retain the zero clearance

ability of the insert included with this saw, we

recommend only raising the blade into the

insert at 90° during the following step.

— if you need a zero clearance insert for

compound cuts, install an optional phenolic

zero clearance table insert, model t21879

(refer to

page 58) for each angled cut, then

proceed to

Step 7.

—

if you plan to use a dado blade to cut rab-

bets or dados, install the optional dado

table insert, model t21878 (see

page 58).

— if you do not require your insert to have a

zero clearance fit, especially if you need to

make a range of compound cuts, you can

modify the insert included with this saw.

Continue with

Step 7, then route the under-

side of the blade-cut slot to the same width

as the rear opening (see

Figure 71).

7. Connect the saw to power. Keep hands off

of table top, do not stand directly behind the

blade path, and wear eye protection.

8. turn the saw ON, then slowly raise the blade

to the maximum height that will be used dur-

ing normal operations.

9. turn the saw OFF, lower the blade complete-

ly, then remove the board and clamps.

10. install the blade guard (refer to "installing

Blade guard & spreader" on

page 35).

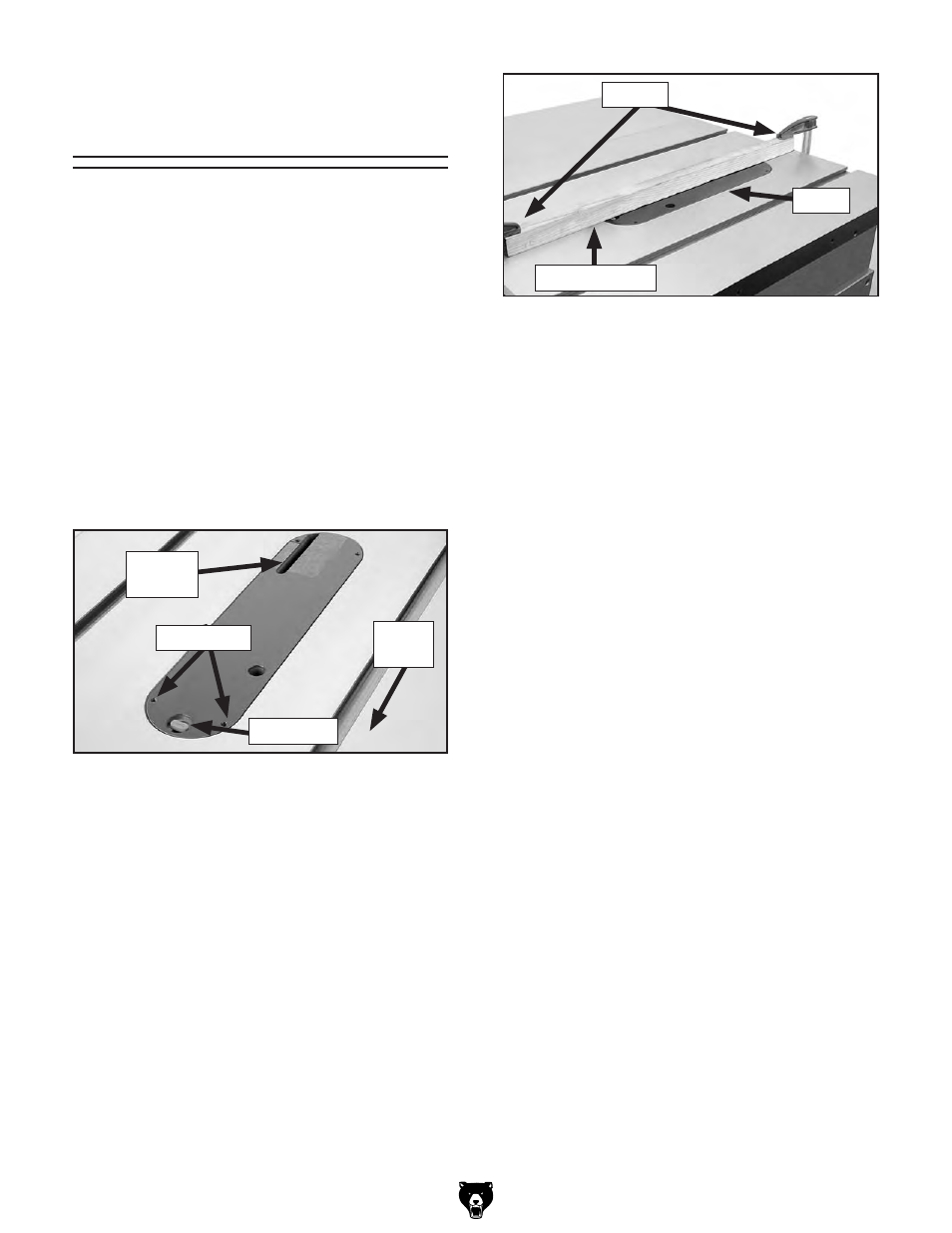

Figure 72. securing insert with board and

clamps.

Clamps

2" thick Board

insert

cutting a zero

clearance Insert

A zero clearance insert is provided with the table

saw to reduce workpiece tear out and increase

user safety. the insert can be customized to fit a

specific blade height or blade angle for the appli-

cable cutting operation.

To install the zero clearance insert:

1. disConnECt sAW From poWEr!

2. Check to make sure the blade is properly

installed (refer to the instructions in

Blade

Installation on page 34).

3. install the table insert, as shown in Figure

71.

4. Adjust the table insert set screws with a

2.5mm hex wrench to make sure the insert is

flush with the table (use a straightedge as a

guide), then turn the lock knob to secure the

insert.

Figure 71. insert knob in lock position.

lock Knob

rear

opening

set screws

Front

of saw