Correcting phase polarity, Grounding instructions phase converter precaution, Magnetic switch assembly mpe-30 – Grizzly G0696X User Manual

Page 15: Extension cords (220v only)

-12-

g0605X1-6X1, g0696X-97X (mfg. 8/11+)

correcting phase

polarity

Grounding Instructions

phase converter precaution

the power from the manufactured leg may dam-

age electrical components if connected to the

wrong incoming power terminal on your machine.

only connect the manufactured leg to the

T/5/L3 terminal (see page 81 for identification).

this sub-section is only provided for troubleshoot-

ing the model g0606X1/g0697X. if you discover

during the test run that the table saw will not

operate, or that the blade runs backwards, the

table saw may be wired out of phase. Without

the proper test equipment to determine the phase

polarity of power source legs, wiring machinery

to 3-phase power may require trial-and-error.

Correcting this is simply a matter of reversing the

positions where two of the incoming power source

wires are connected.

To correct wiring that is out of phase:

1. push the stop button and disconnect the

machine, or shut oFF and lock out the power

source if hardwired.

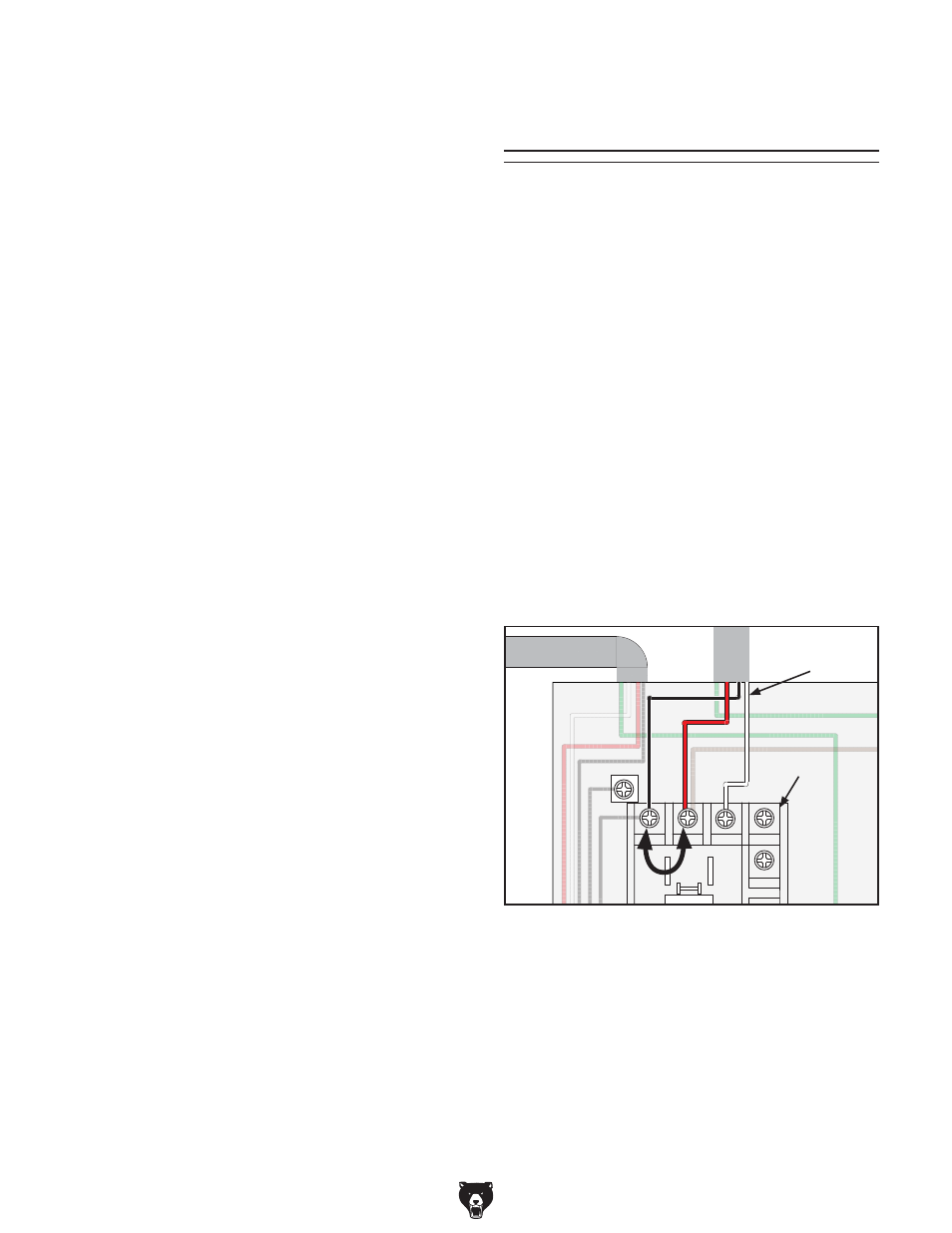

2. remove the magnetic switch cover and

disconnect the l1 and l2 wires, shown in

Figure 5.

Figure 5. Example of switching incoming power

wires l1 and l2.

3. Connect the l1 wire to the terminal where the

l2 wire was connected originally.

4. Connect the l2 wire to the terminal where the

l1 wire was connected originally.

5. re-install the magnetic switch cover, then

reconnect the machine to the power source.

RESET

96

98

1/2

3/4

R/1/L1

T/5/L3

NO13

S/3/L2

5/6

11

22

OFF

NC15

U/2/T1

W/6/T3

220V

V/4/T2

NC16

NO14

95

A

SDE

MA-30

SDE RA-30

B

460V

230V

Ground

Hot

Hot

Hot

Magnetic

Switch

Assembly

MPE-30

Contactor

incoming

power Wires

Extension cords (220v Only)

We do not recommend using an extension cord

with this machine. If you must use an extension

cord, only use it if absolutely necessary and only

on a temporary basis.

Extension cords cause voltage drop, which may

damage electrical components and shorten motor

life. Voltage drop increases as the extension cord

size gets longer and the gauge size gets smaller

(higher gauge numbers indicate smaller sizes).

Any extension cord used with this machine must

contain a ground wire, match the required plug

and receptacle, and meet the following require-

ments:

Minimum Gauge Size ...........................12 AWG

Maximum Length (Shorter is Better).......50 ft.

Improper connection of the equipment-grounding

wire can result in a risk of electric shock. The

wire with green insulation (with or without yellow

stripes) is the equipment-grounding wire. If repair

or replacement of the power cord or plug is nec-

essary, do not connect the equipment-grounding

wire to a live (current carrying) terminal.

Check with a qualified electrician or service per-

sonnel if you do not understand these grounding

requirements, or if you are in doubt about whether

the tool is properly grounded. If you ever notice

that a cord or plug is damaged or worn, discon-

nect it from power, and immediately replace it with

a new one.

This machine MUST be grounded. In the event

of certain malfunctions or breakdowns, grounding

reduces the risk of electric shock by providing a

path of least resistance for electric current.