Operator’s manual, 64 / self test error codes – Great Plains DICKEY-john Seed Manager SE Operator Manual User Manual

Page 66

OPERATOR’S MANUAL

Seed Manager SE

11001-1359A-200810

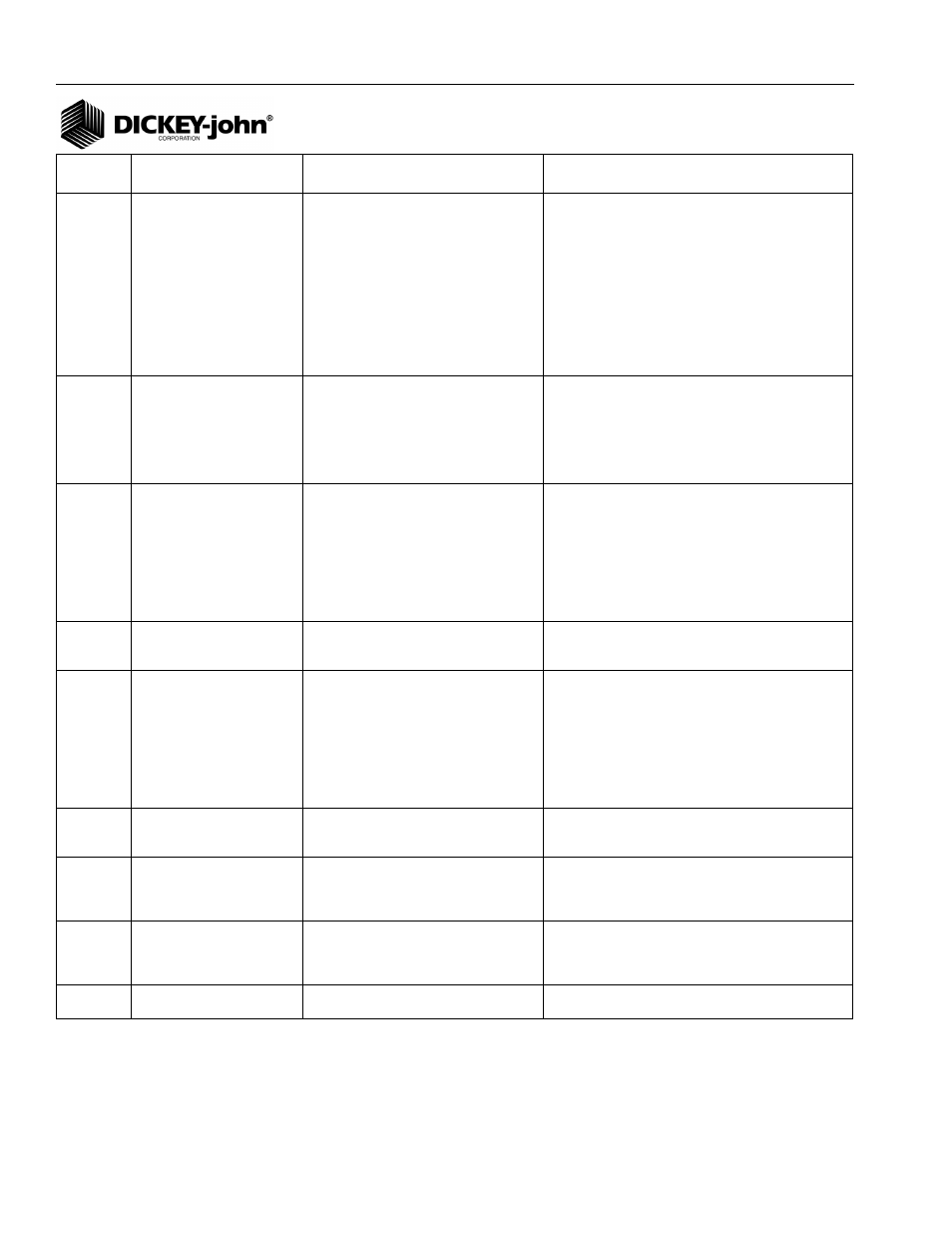

64 / SELF TEST ERROR CODES

E30 X

Too few seed sensors are

connected to module X (X is

the number of the module,

and modules are numbered

from the far left side of the

implement to the far right

side of the implement).

1. Failed seed sensors.

2. Number of Seed Sensors for Module X

Configuration is incorrect.

3. Seed sensors not connected

sequentially.

4. Implement harness is not connected to

all seed sensors.

5. Harnessing cut and/or pinched.

1. Contact DICKEY-john Technical Support at

1-800-637-3302 for a replacement sensor.

2. Check the Number of Seed Sensors for Module X

Configuration in Setup Mode with the actual number of

seed sensors connected.

3. Seed sensors on each module must be connected

from the lowest to highest row inputs without skipping

rows.

4. Check harness connection to sensor number that

corresponds with the number in the lower display.

5. Locate the fault and repair wires by splicing,

soldering, and sealing wires.

E31 X

Too many seed sensors are

connected to module X (X is

the number of the module

and modules are numbered

from the far left side of the

implement to the far right

side of the implement).

1. Number of Seed Sensors for module X

configuration is incorrect.

2. Implement harness is connecting the

wrong seed sensors to module X.

1. Check the Number of Seed Sensors for Module X

Configuration in Setup Mode with the actual number of

seed sensors connected.

2. Check harness connection to sensor number that

corresponds with the number in the lower display.

E40

Too few hopper sensors are

connected to the system.

1. Number of Hopper Sensors

Configuration is incorrect.

2. Hopper sensors failed.

3. Implement harness is not connected to

all hopper sensors.

4. Harnessing cut and/or pinched.

1. Check the Number of Hopper Sensors Configuration

in Setup Mode with the actual number of hopper

sensors connected.

2. Contact DICKEY-john Technical Support at

1-800-637-3302 for assistance.

3. Check harness connection to sensor number that

corresponds with the number in the lower display.

4. Locate the fault and repair wires by splicing,

soldering, and sealing wires.

E41

Too many hopper sensors

are connected to the

system.

1. Number of Hopper Sensors

Configuration is incorrect.

1. Check the Number of Hopper Sensors Configuration

in Setup Mode with the actual number of hopper

sensors connected.

E50

Too few pressure sensors

are connected to the

system.

1. Number of Pressure Sensors

Configuration is incorrect.

2. Pressure sensors failed.

3. Implement harness is not connected to

all pressure sensors.

4. Harnessing cut and/or pinched.

1. Check the Number of Pressure Sensors

Configuration in Setup Mode with the actual number of

pressure sensors connected.

2. Contact DICKEY-john Technical Support at

1-800-637-3302 for a replacement sensor.

3. Check harness connection to sensor number that

corresponds with the number in the lower display.

4. Locate the fault and repair wires by splicing,

soldering, and sealing wires.

E51

Too many pressure sensors

are connected to the

system.

1. Number of Pressure Sensors

Configuration is incorrect.

1. Check the Number of Pressure Sensors

Configuration in Setup Mode with the actual number of

pressure sensors connected.

E70

Module supply voltage is too

low (shorted to 5V or to

ground).

1. Harnessing cut and/or pinched.

2. Module is defective.

1. Locate the fault and repair wires by splicing,

soldering, and sealing wires.

2. Contact DICKEY-john Technical Support at

1-800-637-3302 for a replacement module.

E71

Module supply voltage is too

high (shorted to 12V)

1. Harnessing cut and/or pinched.

2. Module is defective.

1. Locate the fault and repair wires by splicing,

soldering, and sealing wires.

2. Contact DICKEY-john Technical Support at

1-800-637-3302 for a replacement module.

E98-E99

Internal console error.

1. Contact DICKEY-john Technical Support at

1-800-637-3302 for a replacement module.

ERROR

CODE

ISSUE

PROBABLE CAUSE

CORRECTIVE ACTION