GxT Ferret 54 ENGINE DIAGNOSTIC CENTER User Manual

Page 96

PRINTER WARNING MESSAGE

The cause of the printer message is

generally a paper jam, causing the print head

to move too slowly or not at all.

Pulling paper backwards is not

recommended because it can cause wear on

the paper advance mechanism. However, in

the case of a paper jam it may be necessary

to pull the paper backwards. Remove

jammed paper slowly to minimize tearing,

and to remove pieces that are as large as

possible. Paper that is exposed at the tear

bar should be slowly removed by pulling in

the forward direction.

It may be necessary to use tweezers to

remove paper that is jammed to either side

by the print head.

Make a square cut across the leading edge

of the paper roll and insert it into the paper

inlet. Press the Paper Advance button in the

printer compartment to advance the

mechanism. The paper should feed through

easily.

If the problem can not be resolved, contact

the factory for assistance.

FACTORY SERVICE MESSAGE

The cause of this message is an internal

error, and the factory should be consulted.

Have the displayed service code available to

help the factory determine what action is

necessary.

FACTORY SERVICE MAY BE REQUIRED

Service code is: XXXX

Press PRINT for copy of this message.

9-3

TEST LEAD CHECKS

Many of the test leads can be checked

using built-in system diagnostics found

in the

Diagnostic Center Setup

menu.

Select the desired test and follow the screen

instructions.

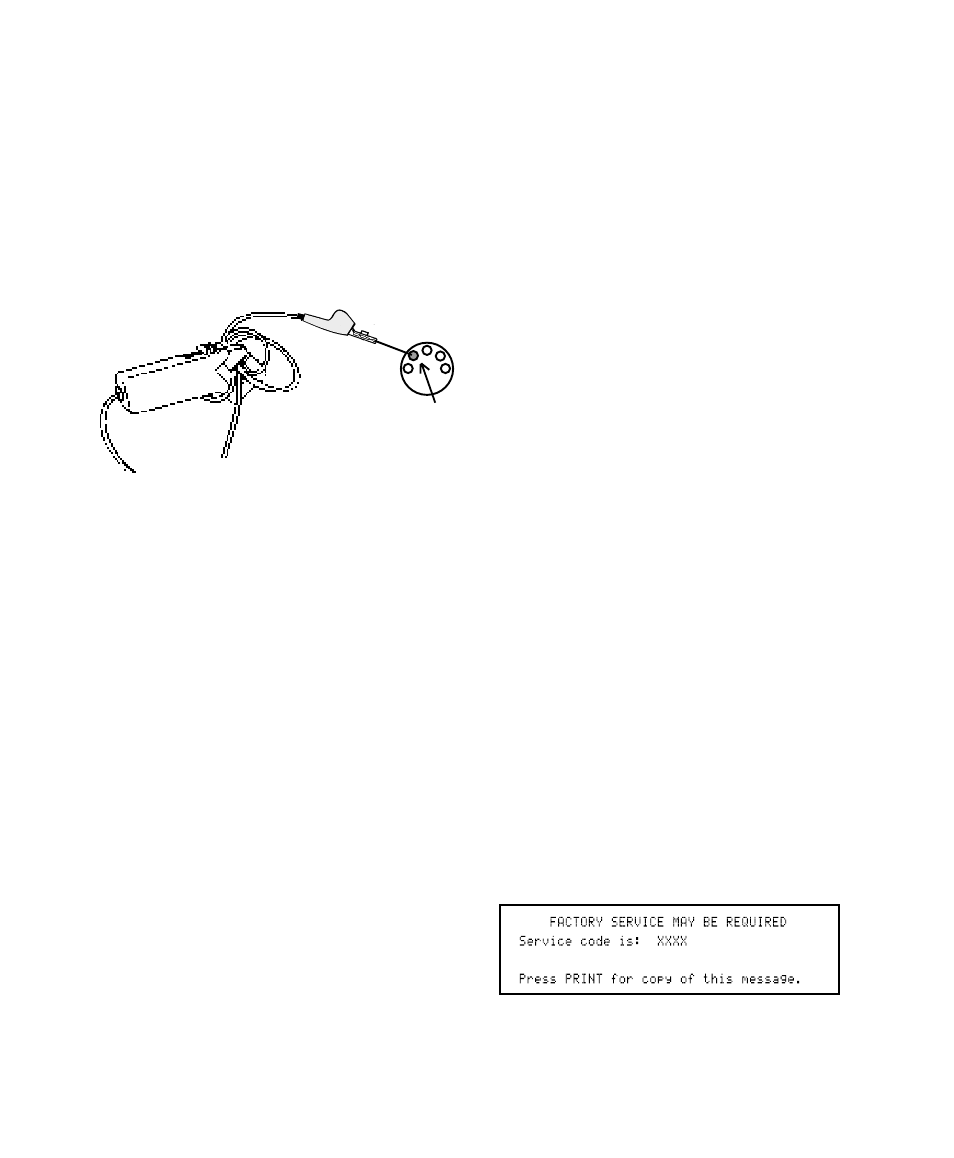

Cylinder #1 Pickup Check

Refer to the diagram below while following

the on-screen instructions.

ELECTRICAL INTERFERENCE

Electrical interference, if significant, may

cause the Diagnostic Center to reset

unexpectedly. Common sources are:

•

Intermittent battery connections

•

Arcs in secondary circuit caused by

broken sparkplug wire insulation or dirt,

that can allow sparks to track along the

outside of a wire.

•

Metallic (nonresistance) wires radiate

radio interference that, if severe, can

disrupt operation. Replacing the coil to

distributor wire with a resistive wire while

testing can help.

•

Pass the Coil (-) lead through the

Cylinder #1 pickup four times, so that

the lead comes out the side labeled

"Spark Plug".

•

Close the pickup jaw.

•

Use a short length of stiff wire with the

multipurpose clip to probe Pin 2 of the Oil

Temperature Socket. This is most easily

done through the extension lead.

Oil Temp

Plug

Pin

2

Cyl. #1

Pickup

Coil (-)

Lead