Calibrate – GxT Ferret 54 ENGINE DIAGNOSTIC CENTER User Manual

Page 87

Following this, air is drawn through the

sample system to determine the flow

normally delivered during sampling. The

sample hose should be placed where it can

freely draw fresh air. No sharp bends or

restrictions should be allowed to inhibit the

flow of air.

When prompted by the display, begin the

flow of Calibration Gas.

Slowly adjust the regulator so that the bar

graph ends between the marks shown on the

display.

Press NEXT when the graph is between the

marks.

While the Gas is flowing, a high-pitched

whine or buzz may be heard. This is from the

action of the check valve and is not an

indication of a problem.

After the calibration is completed, a prompt

will appear to turn off the calibration gas.

Turn the calibration gas bottle valve off (fully

clockwise), and adjust the regulator to off

(fully counterclockwise).

If the flow is not in the proper range, or the

Gas sample measurement does not come

close to the selected Calibration Gas values,

a warning message will appear and the

Calibration process will not be completed.

CALIBRATE

To maintain the accuracy of the Gas

Detector, periodic calibration with known

concentrations of gas are required. Monthly

calibration is recommended for general

diagnostic use. State mandated programs

may require specific calibration schedules.

Preparation

Be sure that the calibration gas bottle valve

is off (fully clockwise), and that the hose from

the regulator to the Gas Detector is

connected. Adjust the regulator to off (fully

counterclockwise).

Procedure

The calibration procedure begins with

selection of the Calibration Gas

concentrations to be used. A Calibration gas

selection screen will appear. Refer to the tag

on the bottle, and select the matching

concentration from the list.

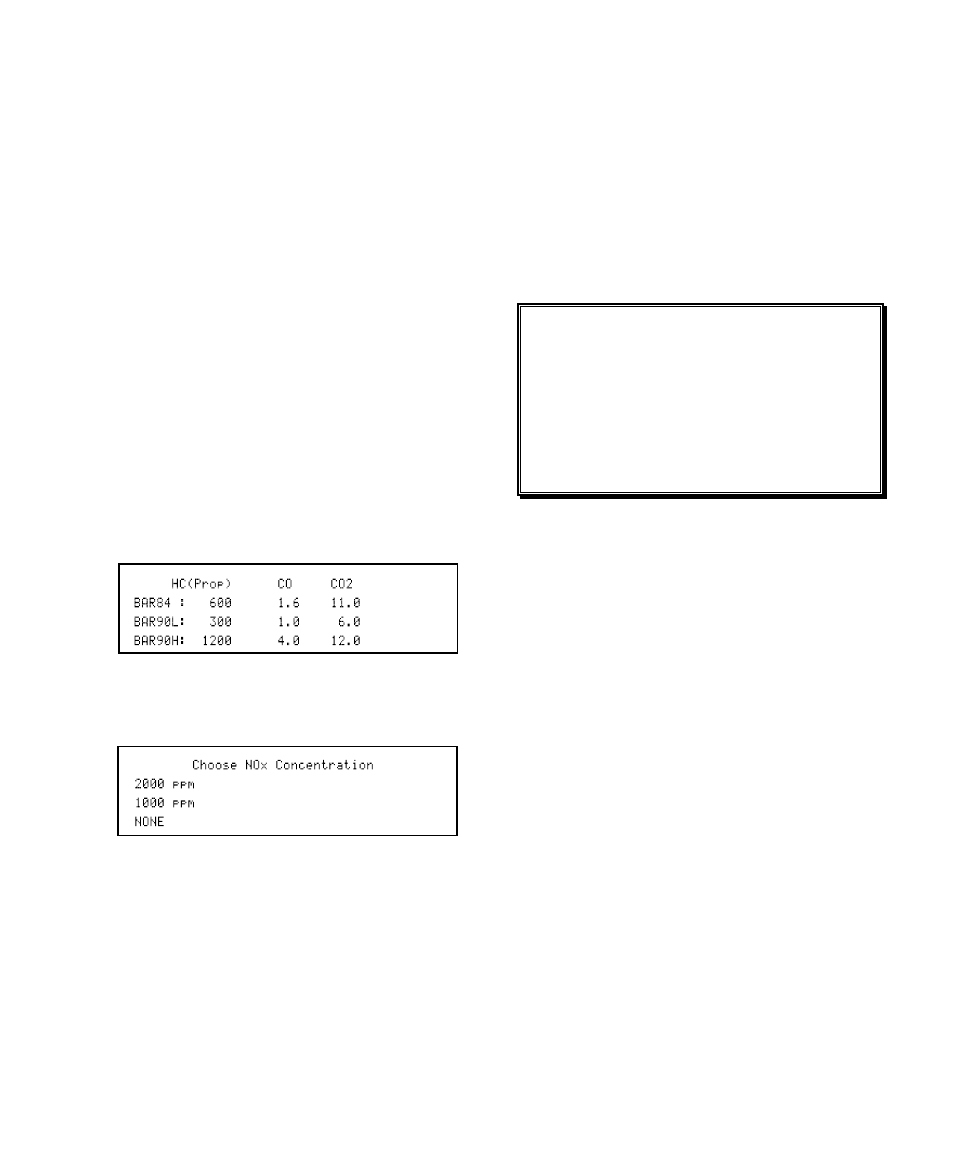

HC(Prop) CO CO2

BAR84 : 600 1.6 11.0

BAR90L: 300 1.0 6.0

BAR90H: 1200 4.0 12.0

Press NEXT and select the proper NOx

concentration.

Choose NOx Concentration

2000 ppm

1000 ppm

N O N E

The concentration numbers marked on the

calibration gas bottle may not match one of

the screen choices exactly. If that is the

case, and the numbers are close, use the

screen choice that most closely matches.

The calibration continues with the ZERO

process; air is drawn through an internal filter

to adjust for zero concentration levels.

8-2

T

HIS

IS

THE

ONLY

TIME

THE

VALVE

ON

THE

C

ALIBRATION

G

AS

BOTTLE

SHOULD

BE

OPENED

!

A

LLOWING

C

ALIBRATION

G

AS

TO

FLOW

DURING

ZERO

ING

OR

SAMPLING

MAY

RESULT

IN

ERRORS!!