2 led checks – Emerson Process Management ControlWave EFM 3808 User Manual

Page 122

3-6 / Service

CI-ControlWave EFM

+16Vdc), you can determine the point at which the unit turns off, i.e., the point at which the

PWRGOOD LED on the SCM goes OFF (Vt-). If the value of the bulk power supply’s +6Vdc

or +12Vdc output approaches the value of Vt+ or Vt- it should be replaced by a power

supply with the correct +6V or +12V output.

JP5, JP6, JP7, JP8 & JP9

1-to-2 Installed = 12V Bulk System

2-to-3 Installed = 6V Bulk System

P1

1

1

2

JP9

JP8

JP6

JP5

JP7

1

1

1

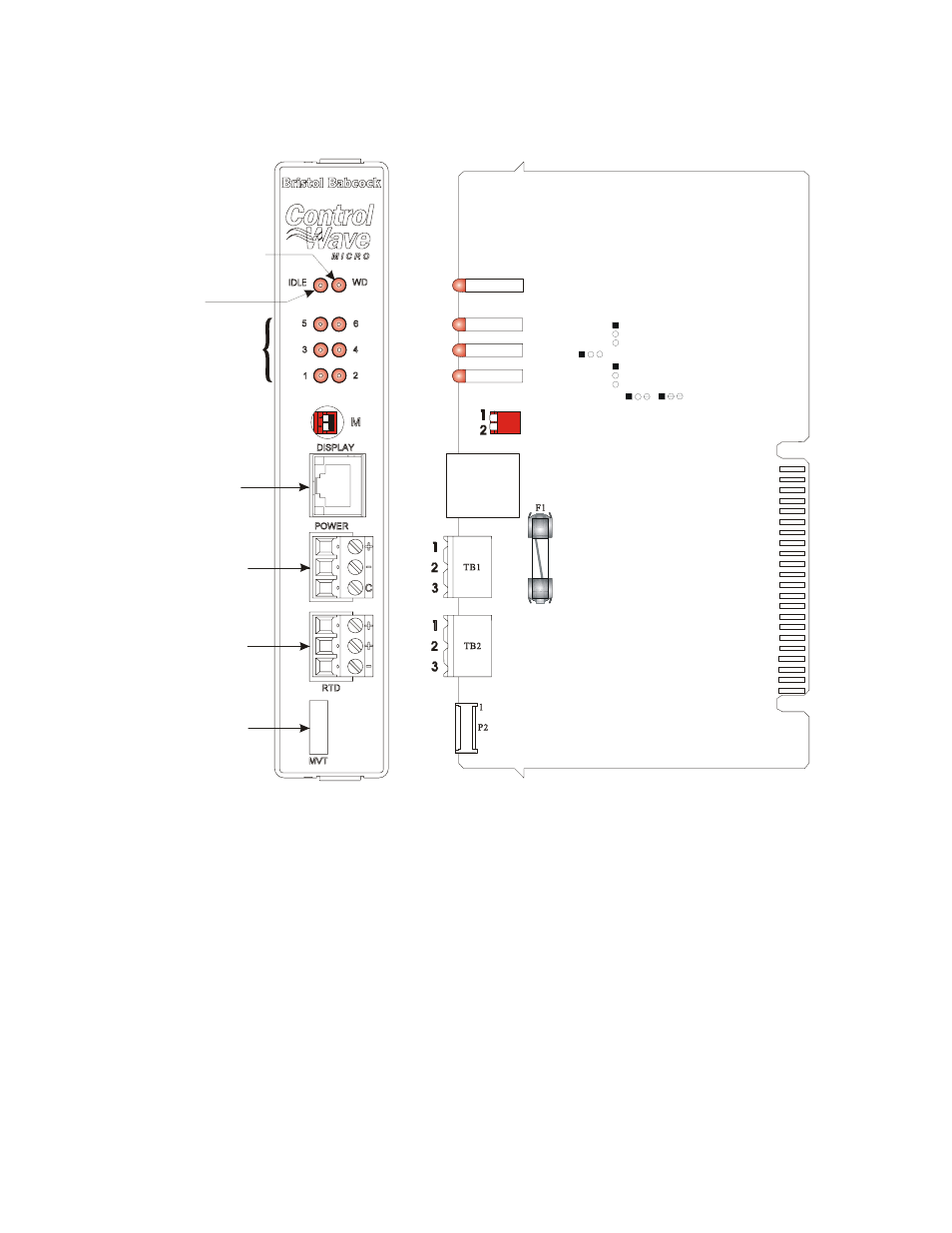

CR27

CR26

CR25

CR24

(Red)

IDLE LED

(Red)

Sta us LEDs

TB1

Input Power

Connector

(Red)

WATCHDOG LED

TB2

RTD Interfa ce

Connector

P2

MVT Interface

Connector

J2

Displa y Intf.

Connector

1A

J2

RJ-45

TB1-1

TB1-2

TB1-3

(+4.5/4.9Vdc to +16.0Vdc for +6V supply)

+VIN (+9.6/10.3Vdc to +16.0Vdc for +12V supply)

-VIN (Supply Ground)

Chassis Ground (CHASSIS)

SW1 = Mode Switch

Figure 3-2 - System Controller Module’s Component & LED Designations

3.3.2 LED Checks

All ControlWave EFM Modules contain light emitting diodes (LEDs) that provide

operational and diagnostic functions. A brief synopsis of the individual module LEDs is

provided as follows:

SCM:

1 IDLE LED, 1 Watchdog LED, & 6 System Status LEDs

CPUM:

2 LEDs per Comm. Port = 6

ECOM1: 2 LEDs per Comm. Port = 8

ECOM2: 2 LEDs per Comm. Port = 8

AI/OM: None

DI/OM: 1 LED per DI x 12 = 12 DI LEDs, 1 LED per DO x 4 = 4 DO LEDs

HSCM:

1 LED per HSC x 4 = 4 HSC LEDs

MI/OM: None