LINK Systems OmniLink 5000 User Manual

Page 56

5.9

Stroke

Mode Single Stroke

Drive

Speed

Stroke

Speed

SPM

SPM

200

0

Order

Counter

PC STATUS

Counter OFF

MACHINE

PARAMETERS

CHANGE

NUMBER

0

0

Program/Run Switch

TOP

EXIT

SET

ZERO

FACTORY

CONFIG

SPEED

CONFIG

Parameter

Setting

Encoder Offset……………………..

Auto Carry Up ……………………..

Begin Timed Inch………………….

Minimum Strokes / Min …………..

Maximum Strokes / Min ………….

Motion Filter ……………………….

Clutch Engagement ……………...

Timed Inch Pulse …………………

Automatic Turn Off ……………….

Max. # Engage/Min ………………..

Top Stroke Stop Time …………….

Mid Stroke Stop Time …………….

1

180

100

50

200

1

200

50

0

0

200

240

deg

deg

deg

Spm

Spm

mS

mS

Min

mS

mS

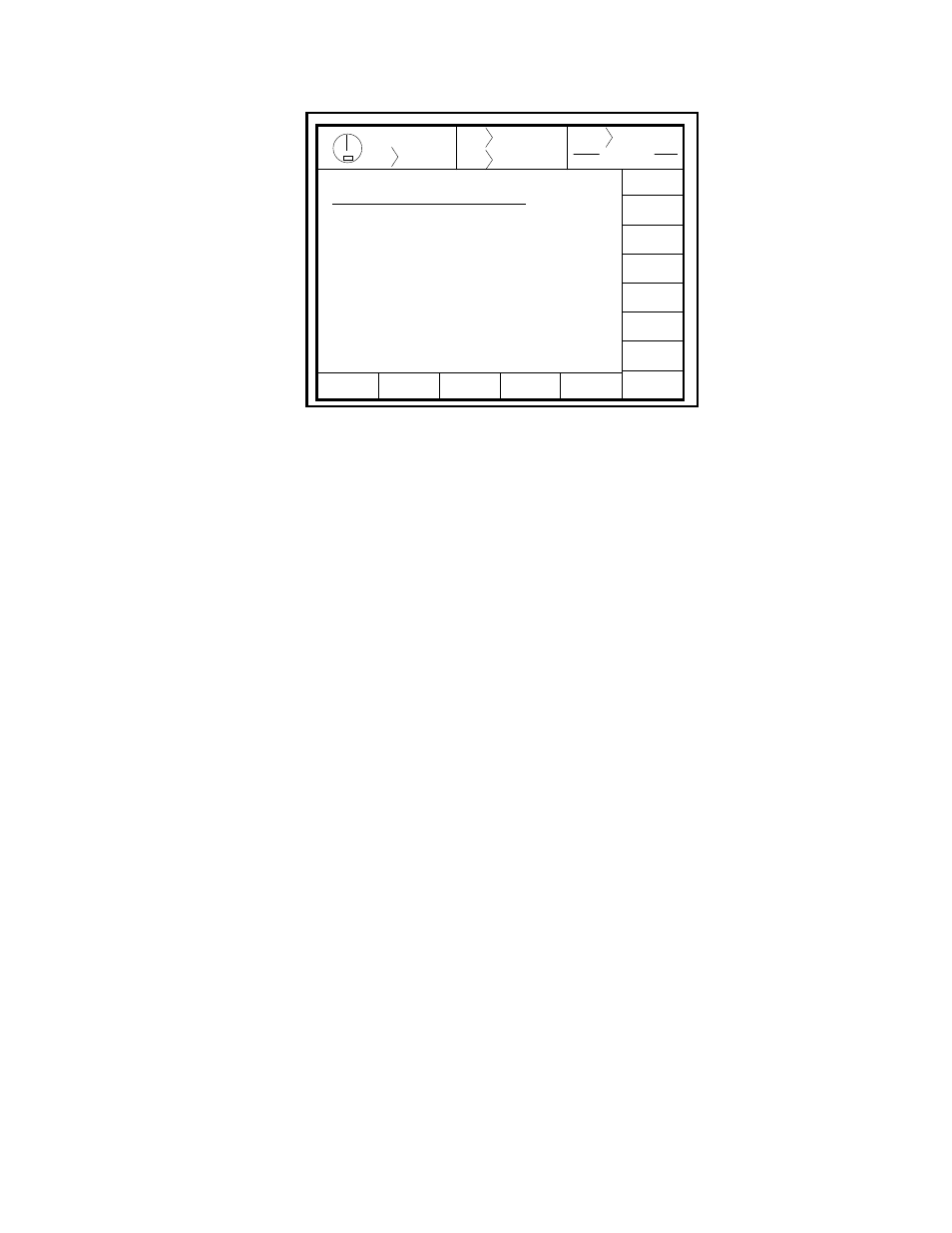

Figure 5.5 Machine Parameters

Configuration

Section 5.2.1 Encoder Offset

The offset is to compensate for misalignment between the resolver/encoder zero and the machine zero. To

enter, the user must position the crankshaft at top dead center and press the SET ZERO softkey. The offset

value displayed is the number that must be added to the actual resolver reading to get 0°. If the present

resolver angle is within the allowable limit, the angular display value will indicate 0°. This value is limited

to ± 10° from resolver zero. If the position is beyond the limit, the limit is used as the offset. Coarse

adjustment is provided by allowing manual entry of 0°-9° or 350°-359°.

Section 5.2.2 Automatic Carry Up Position

This parameter is the angle at which the press control will automatically keep the clutch/brake valve engaged

until the machine reaches the top of the stroke. It is used only in Single Stroke and Automatic Single Stroke

modes. Once this angle is reached, an operator may release the run buttons without causing the press to stop.

This value is limited to between 120° and 180°, and an entry beyond the limit is rejected.

Section 5.2.3 Begin Timed Inch Position

This parameter is the angle in the downstroke at which the press control will enter timed inch. It is used only

if the Timed Inch mode is selected. The timed inch function will continue until the crankshaft angle reaches

180°, or another stroking mode is selected. This value is limited to between 0° and 135°, and an entry

beyond the limit is rejected.

Section 5.2.4 Minimum Strokes/Minute

This parameter is the minimum speed threshold for the motion detector. It is used to verify clutch

engagement and to detect loss of resolver/encoder motion due to a failure in mechanism (chain etc.) that

connects the resolver/encoder to the crankshaft. The threshold is used to indicate the start of motion or the

loss of motion and should therefore be set well below the actual minimum operating speed of the press. This

value is limited to between 2 and 100 rpm, and an entry beyond the limit is rejected. Entries are rounded to