LINK Systems OmniLink 5000 User Manual

Page 24

4.6

1

L. N.O. INCH BUTTON

LO

LO

2

R. N.O. INCH BUTTON

LO

LO

3

L. N.O. STATION # 1

LO

LO

4

R. N.O. STATION # 1

LO

LO

5

L. N.O. STATION # 2

LO

LO

6

R. N.O. STATION # 2

LO

LO

7

L. N.O. STATION # 3

LO

LO

8

R. N.O. STATION # 3

LO

LO

9

L. N.O. STATION # 4

LO

LO

10

R. N.O. STATION # 4

LO

LO

11

ALL N.C. RUN BUTTONS

HI

HI

12 T-STOP

TOP STOP

HI

HI

13 E-STOP

EMERGENCY STOP

HI

HI

14 E-STOP

EMERGENCY STOP

HI

HI

15 E-STOP

LIGHT CURTAIN 1

HI

HI

16 E-STOP

LIGHT CURTAIN 2

HI

HI

17

STATION 1 SELECT

HI

HI

18

STATION 2 SELECT

LO

LO

19

STATION 3 SELECT

LO

LO

20

STATION 4 SELECT

LO

LO

21

MODE (RUN)

HI

HI

22

MODE (MODE SELECT)

LO

LO

23

AUTOMATIC SETUP

LO

LO

24

CONTINUOUS SETUP

LO

LO

Stroke

Mode Single Stroke

Drive

Speed

Stroke

Speed

SPM

SPM

0

0

Order

Counter

PC STATUS

Counter OFF

INPUT

DIAGNOSTIC

VIEW

OUTPUTS

MEMORY

COMPARE

EVENT

LOG

EXIT

0

0

READY TO STROKE

TOP

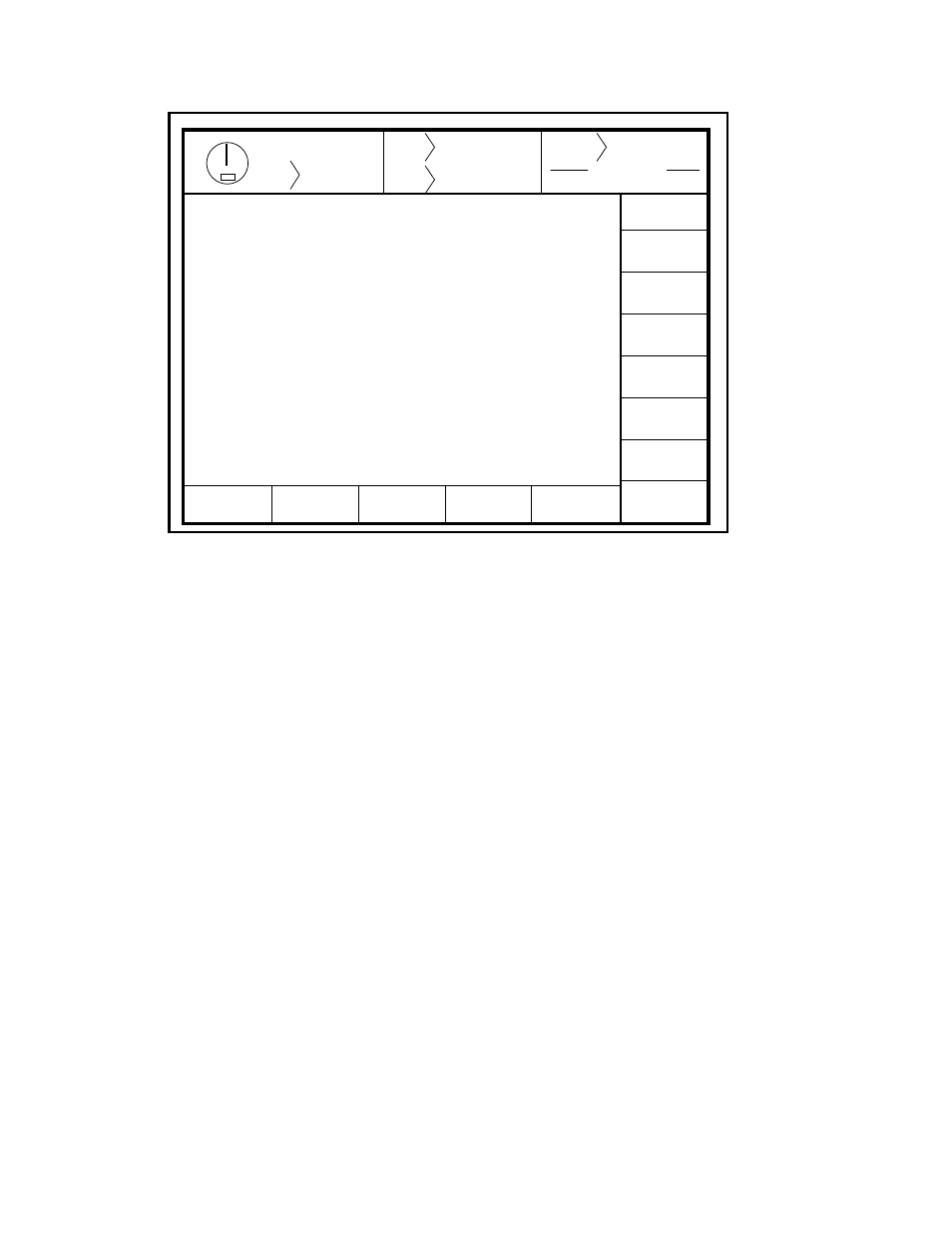

Input Module 1

Num Type

Name

CHA

CHB

NEXT

PAGE

VERSION

INFO

Figure 4.3 Input Diagnostics

Section 4.2.9.2 Output Diagnostics

This screen functions similarly to the input diagnostics. This screen will show that status of the outputs.

These are Output Relays 1-16. The state indicates the condition of the output, where HI=Output On and

LO=Output Off. The status of the programmable limit switch outputs is shown on the programmable limit

switch screen.

Section 4.2.9.3 Press Control Memory Test

This menu compares the internal memory of both channels of the press control and displays any locations that

do not agree. If any parameter of either channel becomes corrupt, an error message is displayed and stroke

initiation is inhibited. Either error message "MEMORY CHECK FAULT" or "MEMORY COMPARE

FAULT" displayed in the press control's present running status indicates that a system parameter is corrupt,

and this diagnostic menu should be used to determine which parameter is bad. All locations indicated as bad

must be reprogrammed before the fault condition can be cleared. The memory comparison is done in groups,

and all are accessed with the NEXT GROUP softkey. The parameters programmed by the factory (Group

4 and 5) are not accessible by the user, but can viewed from this menu. The items tested are described below:

Group 1

Programmed in Press Control configuration and Auto Sets screens.

01

Stop time limit at the top of stroke

02

Stop time limit at mid-stroke

03

Automatic Single Stroke Time

04

Feed Complete Position

05

Continuous on Demand Time