A warning – Carrier 48SX024-048 User Manual

Page 40

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

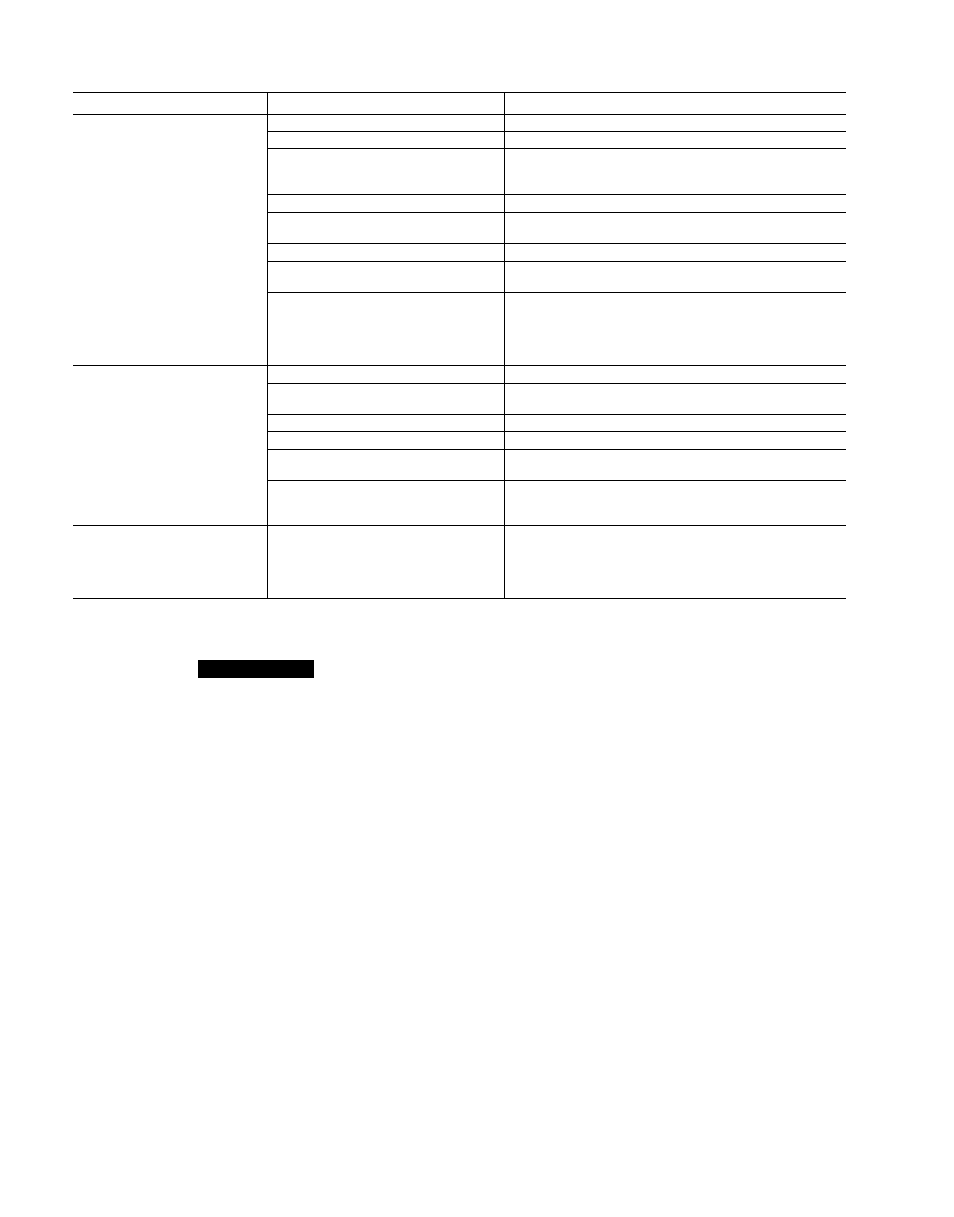

Table 15 — Heating Troubleshooting Chart

SYMPTOM

CAUSE

REMEDY

Burners will not ignite.

Water in gas line

Drain. Install drip leg.

No power to furnace

Check power supply fuses, wiring, or circuit breaker.

No 24-v power supply to control

circuit

Check transformer.

NOTE: Some transformers have internal overcurrent

protection that requires a cool-down period to reset.

Miswired or loose connections

Check all wiring and wirenut connections.

Burned-out heat anticipator in

thermostat

Replace thermostat.

Broken thermostat wire

Run continuity check. Replace wire if necessary.

Misaligned spark electrodes

Check flame ignition and sense electrode positioning.

Adjust as necessary.

No gas at main burners

1. Check gas line for air. Purge as necessary.

NOTE: After purging gas line of air, wait at least

5 minutes for any gas to dissipate before attempt

ing to light unit.

2. Check gas valve.

Inadequate heating.

Dirty air filter

Clean or replace filter as necessary.

Gas input to furnace too low

Check gas pressure at manifold. Match with that on

unit nameplate.

Unit undersized for application

Replace with proper unit or add additional unit.

Restricted airflow

Clean or replace filter. Remove any restriction.

Blower speed too low

Use faster speed tap if available, or install alternate

motor.

Limit switch cycles main burners

Check rotation of blower, thermostat heat antic

ipator settings, temperature rise of unit. Adjust as

necessary.

Poor flame characteristics.

Incomplete combustion results in:

Aldehyde odors, carbon monoxide,

sooting flame, floating flame

1. Tighten all screws around burner compartment.

2. Cracked heat exchanger. Replace.

3. Unit overfired. Reduce input (change orifices or

adjust gas line or manifold pressure).

4. Check burner alignment.

t

A

WARNING

Turn off the gas supply, then disconnect and tag elec

trical power to the unit before cleaning and lubricating

the blower motor and wheel. Failure to adhere to this

warning could cause personal injury or death.

To clean and lubricate the blower motor and wheel for

direct-drive models:

1. Remove and disassemble blower assembly as follows:

a. Remove blower access door.

b. Disconnect motor lead from blower relay (BR)

Disconnect yellow lead from terminal L2 of the

contactor.

c. Remove blower assembly from unit. Remove screws

securing blower to gas partition and slide assembly

out. Be careful not to tear insulation in blower

compartment.

d. Ensure proper reassembly by marking blower wheel

and motor in relation to blower housing before dis

assembly.

e. Loosen setscrew(s) that secures wheel to motor shaft,

remove screws that secure motor mount brackets to

housing, and slide motor and motor mount out of

housing.

2. Lubricate motor as follows:

a. Thoroughly clean all accumulations of dirt or grease

from motor housing.

b. Remove dust caps or plugs from oil ports located at

each end of motor.

c. Use a good grade of SAE 20 nondetergent motor oil

and put one teaspoon (Yie oz. or 16 to 25 drops) in

each oil port.

d. Allow time for oil to be absorbed by each bearing,

then wipe excess oil from motor housing.

e. Replace dust caps or plugs in oil ports.

3. Remove and clean blower wheel as follows:

a.

Ensure proper reassembly by marking wheel

orientation.

b. Lift wheel from housing. When handling and/or clean

ing blower wheel, be sure not to disturb balance weights

(clips) on blower wheel vanes.

c. Remove caked-on dirt from wheel and housing with

a brush. Remove lint and/or dirt accumulations from

wheel and housing with vacuum cleaner, using soft

brush attachment. Remove grease and oil with mild

solvent.

d. Reassemble wheel into housing.

e. Reassemble motor into housing. Be sure setscrews

are tightened on motor shaft flats and not on round

part of shaft.

f. Reinstall blower access door.

4. Restore electrical power, then gas supply to unit. Start

unit and check for proper blower rotation and motor speeds

during heating and cooling cycles.

t

40