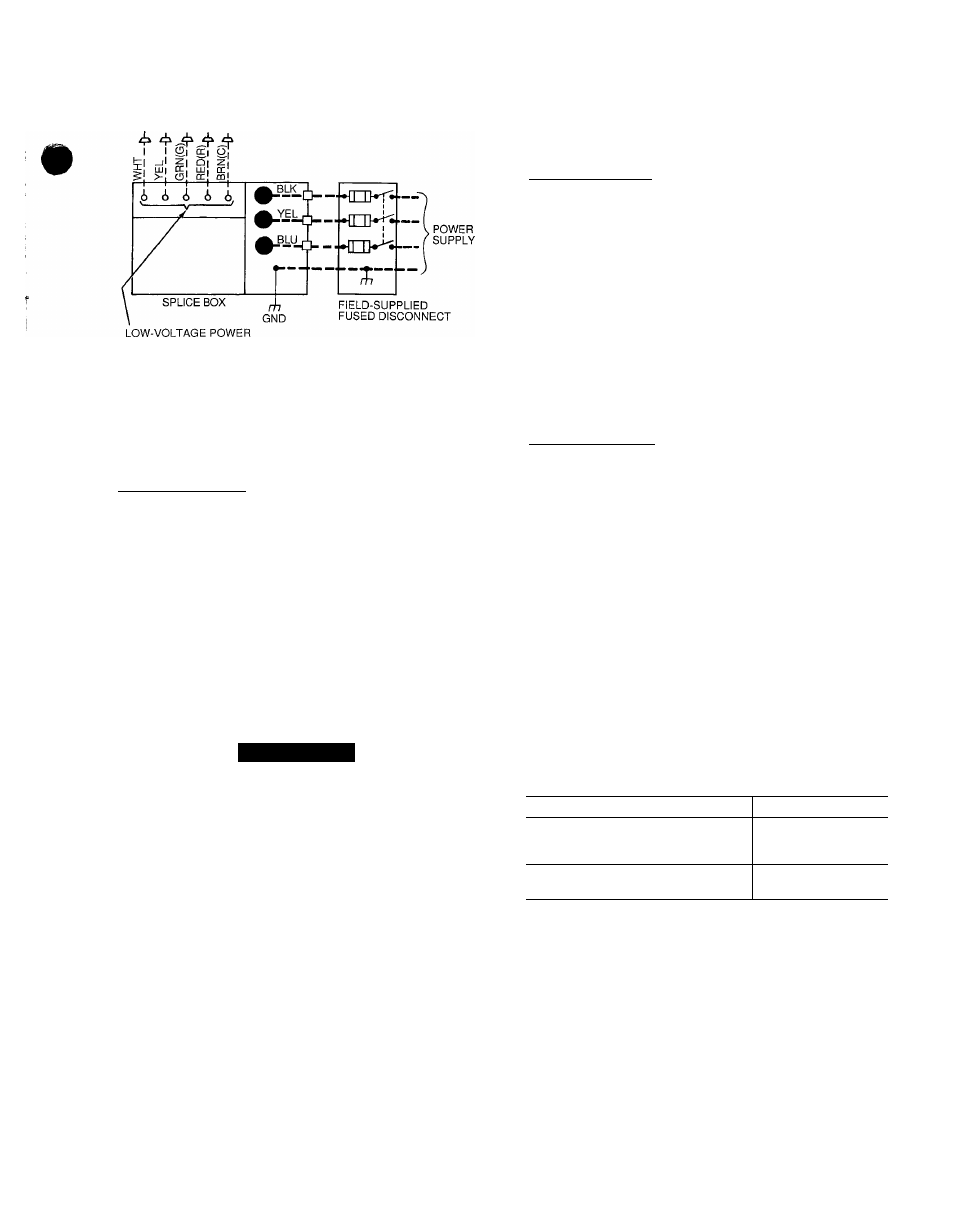

Fig. 21 — high- and control-voltage connections, A warning – Carrier 48SX024-048 User Manual

Page 19

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

THERMOSTAT (TYPICAL)

(^(

y

)(^(R)0

LEADS (SEE UNIT

WIRING LABEL)

LEGEND

--------- Field Control-Voltage Wiring

------- — Field High-Voltage Wiring

NOTE: Use biue wire for 3-phase units only

Fig. 21 — High- and Control-Voltage Connections

Alternate Power Entry

6

.

Remove knockouts in fixed compressor panel located on

duct panel side of unit.

Route high-voltage leads into high-voltage terminal box.

Connect ground wire to green-yellow wire using field-

supplied splice.

Connect power wires to unit high-voltage leads.

On 3-phase units, locate blue wire projecting from com

pressor junction box. Cut wire at partition and route into

high-voltage junction box through grommet in back of

junction box.

On 3-phase units, strip back blue lead and connect to

third leg of the power wires.

SPECIAL PROCEDURES FOR 208-V OPERATION

A

WARNING

Make sure that the gas supply then the power supply to

the unit is switched OFF before making any wiring

changes. Electrical shock can cause personal injury or

death.

6

.

Disconnect the orange transformer-primary lead from the

contactor. See unit wiring label.

Remove the tape and wirenut from the terminal on the

end of the red transformer-primary lead.

Save the wirenut.

Connect the red lead to the contactor terminal from which

the orange lead was disconnected.

Using the wirenut removed from the red lead, insulate

the loose terminal on the orange lead.

Wrap the cover with electrical tape so that the metal ter

minal cannot be seen.

CONTROL VOLTAGE CONNECTIONS - Locate the room

thermostat on an inside wall in the space to be conditioned,

where it will not be subjected to either a cooling or heating

source or direct exposure to sunlight. Mount the thermostat

4 to 5 ft above the floor

NOTE. Do not use any type of power-stealing thermostat.

Unit control problems may result.

Use no. 18 American Wire Gage (AWG) color-coded,

insulated (35 C minimum) wires to make the control volt

age connections between the thermostat and the unit. If the

thermostat is located more than 100 ft from the unit (as

measured along the control voltage wires), use no. 16 AWG

color-coded, insulated (35 C minimum) wires.

Standard Connection — A grommeted, control-voltage in

let hole is located in the flue panel adjacent to the control

access panel. See Fig 2-9. Provide a drip loop before run

ning wire through panel.

Run the low-voltage leads from the thermostat, through

the inlet hole, and into unit low-voltage splice box.

Locate five 18-gage wires leaving control box. These low-

voltage connection leads can be identified by the colors red,

green, yellow, brown, and white). (See Fig. 21.) Cut wires

at the point where they exit control box. On 48SX024,030,

do not cut yellow wire. Stripped yellow lead is located in

connection box. Ensure the leads are long enough to be routed

into the low-voltage splice box located below the right side

of the control box. Route leads through hole in bottom of

control box and make low-voltage connections as shown in

Fig. 21. Secure all cut wires, so that they do not interfere

with operation of unit.

Alternate Connection — Remove knockout in compressor

fixed panel located below high-voltage knockout. Remove

rubber grommet from standard low-voltage power entry and

install it in hole left when knockout was removed. Route

thermostat wires through grommet providing drip loop at

panel Connect low-voltage leads as shown in Fig. 21. On

48SX024 and 030 units, the yellow wire originating from

discharge thermostat of compressor must be cut and routed

into low-voltage section of junction box.

HEAT ANTICIPATOR SETTING - The room thermostat

heat anticipator must be properly adjusted to ensure proper

heating performance. Set the heat anticipator, using an am

meter between the W and R terminals to determine the

exact required setting.

NOTE: For thermostat selection purposes, use 0.18 amp

for the approximate required setting.

Failure to make a proper heat anticipator adjustment will

result in improper operation, discomfort to the occupants

of the conditioned space, and inefficient energy utilization;

however, the required setting may be changed slightly

to provide a greater degree of comfort for a particular

installation.

Recommended thermostats are as follows:

TYPE

PART NO.

Single-Stage Heating and

Cooling Manual Changeover

HH01AD040*

HH01AD046

HH01PC184

Auto. Changeover

HH07AT174t

HH01PC185

19

•Recommended for use with subbase HH93AZ040

tRecommended for use with subbase HH93AZ176

TRANSFORMER PROTECTION - The unit transformer

protection may be one of 2 types.

The first transformer type may contain an auto, reset over

current protector for control circuit protection. If this de

vice trips, it may reset without warning, starting the heat

ing or cooling section of this product. Use caution when

servicing; if overcurrent protector continues to trip, there is

a problem in the low-voltage electrical circuit, such as an

electrical short, ground, or transformer overload. Discon

nect power, correct the condition, and check for normal unit

operation.

The second transformer type is of the energy-limiting type.

It is set to withstand a 30-second overload or shorted

secondary condition.