Top Flite TOPA0120 User Manual

Page 31

Fuselage Bolt Blocks into the notches in the

fuselage side doublers at Former F-4. Use epoxy

to make a small fillet around the sides of the bolt

blocks. Also make an epoxy fillet between the bolt

block and Former F-4.

❑

16. Use CA+ to finish gluing the fuselage sides

to Formers F-1B, F-2, F-3 and F-4.

❑

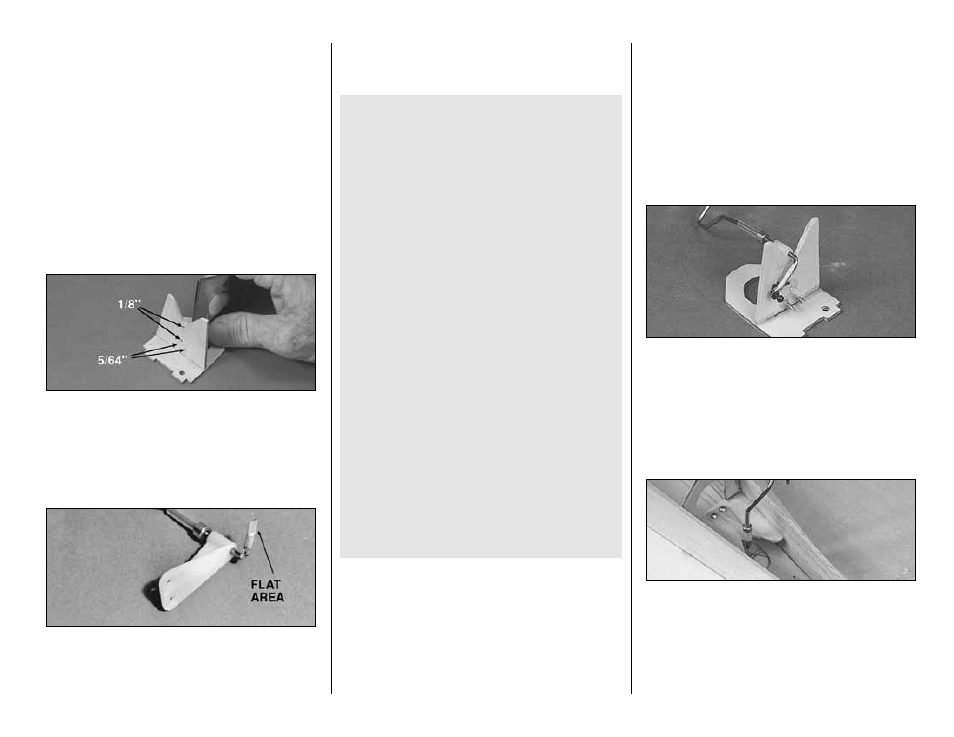

17. Drill 5/64” holes through the forward two

punch marks in the die-cut 1/8” plywood Tail

Wheel Plate (TW). Drill 1/8” holes through the two

AFT punch marks for nylon tail wheel support pegs

(see below).

❑

18. Glue the die-cut 1/8” plywood Tail Wheel

Plate (TW) to former F-8, making sure they are

perpendicular. Make sure the number on F-8

faces down.

❑

19. Place the 5/8” long piece of 1/8” O.D.

brass tubing over the top end of the wire. Squeeze

the exposed end of the tube firmly with pliers to

flatten it. Check the parts over the fuselage top

view to make sure they match up well. Silver

solder the brass tube to the wire (see below).

TIPS FOR SILVER SOLDERING

Use this process when soldering metal to metal

such as brass tube to wire, or pushrod ends to

wire.

A. Thoroughly clean the items to be soldered with

alcohol or degreasing solvent.

B. Roughen the area to be soldered with fine

sandpaper, then clean again.

C. Assemble the items to be soldered.

D. Apply a small amount of soldering flux. Acid

based flux works best when one or more of the

items is steel.

E. Heat the metal with a soldering gun or iron, and

apply solder to the metal. The metal must get

hot enough to melt the solder and the solder

must flow freely into the joint.

F. Do not move the parts until the solder has

cooled.

G. Clean off the excess flux with alcohol or

solvent. Coat the parts with a very fine film of

oil.

H. Test the joint by pulling hard.

❑

20. Mark the location for mounting the Metal

Ball on the flat of the Brass Tube. Drill a 1/16"

hole at the mark.

❑

21. Attach the ball permanently on the tail gear

with the Small Nut provided. Put a drop of

6-minute epoxy on the threads to prevent it from

vibrating loose.

❑

22. Use the 4-40 Set Screw to set the collar at

the height shown on the fuselage side view, but

orient the set screw so small adjustments can be

made later if required.

❑

23. Roughen the tubular Nylon Bearing on

the tail wheel wire with sandpaper so glue will stick

to it.

❑

24. Put a small drop of 6-minute epoxy on the

Nylon Bracket where the bolt holes are. Screw the

Nylon Bracket to TW with two #4 x 3/8” Sheet

Metal Screws. Then put a drop of epoxy on the

threads of the Sheet Metal Screws to prevent them

from vibrating loose.

❑

25. Pin the die-cut 1/8” plywood Stab Support

Crutch to the plans at its location. The fuselage

sides will protrude aft of the Stab Support Crutch

by approximately 3/8”. Glue F-8 to the front edge

of the Stab Support Crutch; it should be

perpendicular to the building board.

- 31 -