Top Flite TOPA0120 User Manual

Page 22

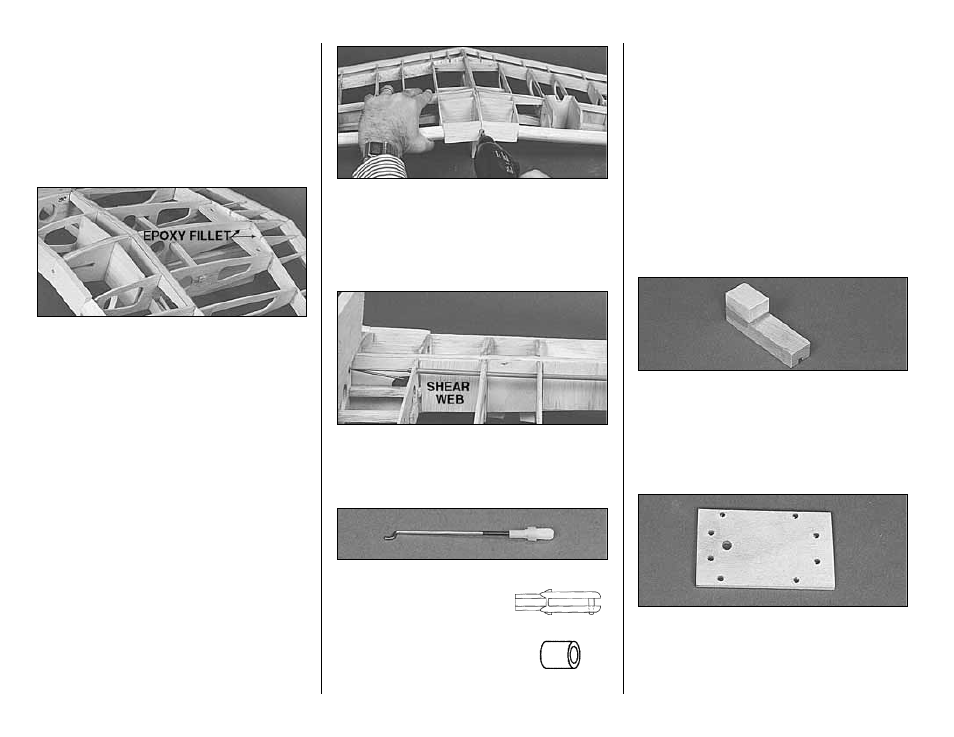

Place the 3/8” x 2-5/8” x 10” balsa Wing Jig Block

under W-1. The W-1 jig tabs and the spar at W-1

should contact the Wing Jig Block. The W-12 jig

tabs and the spar at W-12 should contact your flat

work table.

❑

8. When you have confirmed that all of the

parts fit well, disassemble the wing parts. Coat the

inside of the Dihedral braces and the area of the

Spars that they contact with a thin film of 30-minute

epoxy. Reassemble the wing parts onto the jig

block. Align the two W-1 ribs with each other and

glue them together with CA. Make sure the wing is

properly jigged. Clamp the Dihedral braces to the

Spars with clamps or masking tape.

❑

9. Apply a fillet of 30-minute epoxy around the

Wing Bolt Plate.

❑

10. Use 30-minute epoxy to fill any gaps

where the Spars join in the middle.

❑

11. Drill a 3/16” pilot hole through the wing LE

for the 5/16" Wing Dowel. Gradually enlarge the

hole to 5/16” keeping the drill centered on the two

W-1 ribs.

❑

12. Make a 1/16” balsa shear web to fit

between W-2 and W-3. Glue it to the Dihedral

Brace on the aft side of the spar.

❑

13. Make the aileron pushrods from the 4”

threaded end rod. Use a Nylon

Clevis with a Clevis Retainer on

the horn end and a Z-bend on

the Bellcrank end. Make them

the length shown on the wing

plan top view.

❑

14. Drill out the outer hole in the bellcranks

with a 5/64” drill bit. Test fit the pushrod into the

bellcrank.

FIXED LANDING GEAR ASSEMBLY

Do the following six steps to make a left and a

right fixed gear assembly.

NOTE: The fixed gear is slightly shorter

than scale to improve ground handling.

❑ ❑

1. Use 30-minute epoxy to glue the 3/4” x

5/8” x 1” hardwood Landing Gear Block to one

end of the slotted 1/2” x 3/4” x 2-3/4” hardwood

Landing Gear Rail as shown on the plan and in

the photo.

❑ ❑

2. Locate the 1/8” x 1-11/16” x 2-3/4” birch

plywood Landing Gear Plate. Use the template

provided on the wing plan to mark the hole

locations. Drill the holes to the sizes indicated on

the template.

- 22 -