Seat core, Puron r (r a) refrigerant – Carrier 48TCA04---A12 User Manual

Page 8

8

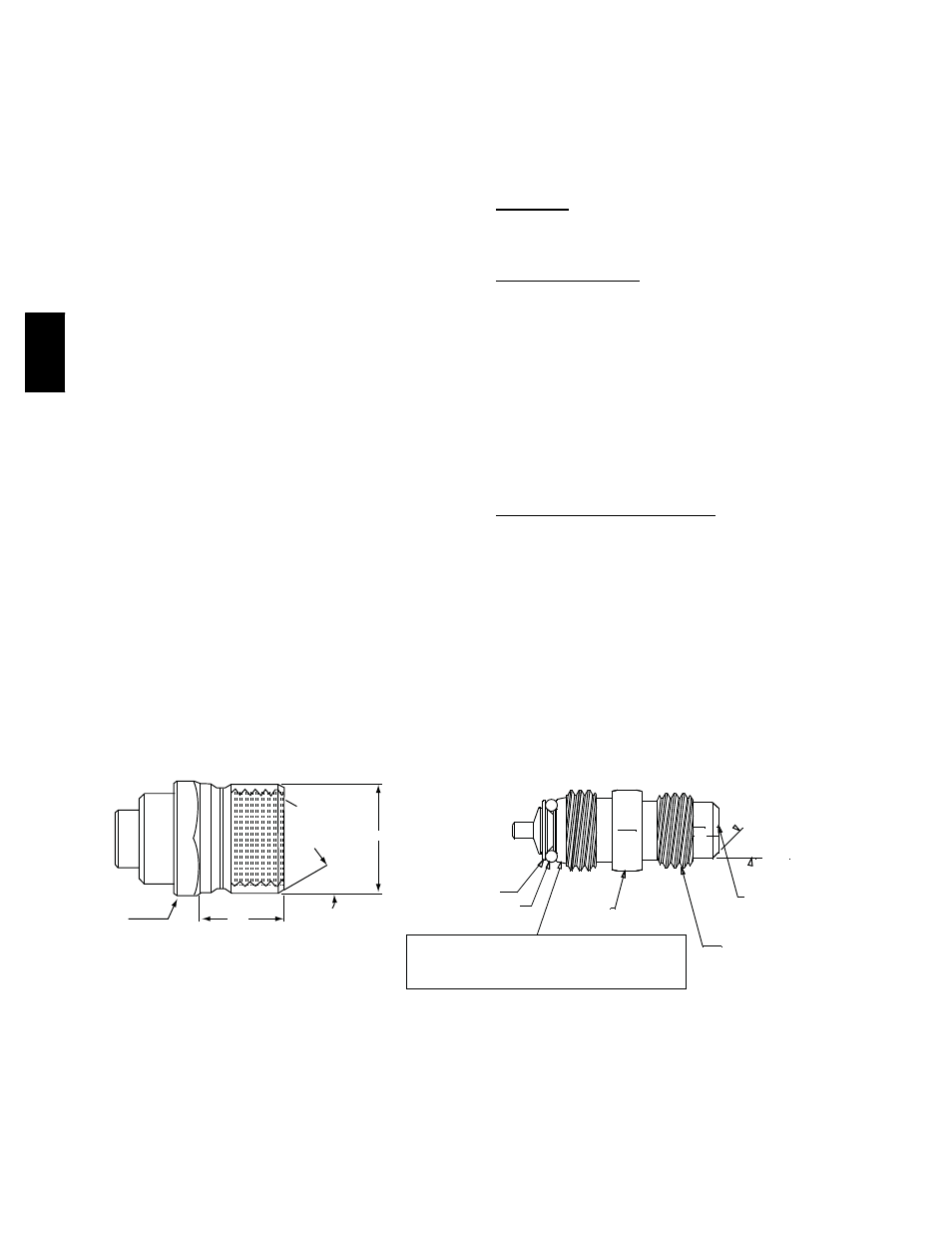

(See Fig. 11.) This check valve is permanently assembled

into this core body and cannot be serviced separately;

replace the entire core body if necessary. Service tools are

available from RCD that allow the replacement of the

check valve core without having to recover the entire

system refrigerant charge. Apply compressor refrigerant

oil to the check valve core’s bottom o--ring. Install the

fitting body with 96 +/ --10 in--lbs of torque; do not

overtighten.

PURONR (R--410A) REFRIGERANT

This unit is designed for use with Puron (R--410A)

refrigerant. Do not use any other refrigerant in this

system.

Puron (R--410A) refrigerant is provided in pink (rose)

colored cylinders. These cylinders are available with and

without dip tubes; cylinders with dip tubes will have a

label indicating this feature. For a cylinder with a dip

tube, place the cylinder in the upright position (access

valve at the top) when removing liquid refrigerant for

charging. For a cylinder without a dip tube, invert the

cylinder (access valve on the bottom) when removing

liquid refrigerant.

Because Puron (R--410A) refrigerant is a blend, it is

strongly recommended that refrigerant always be removed

from the cylinder as a liquid. Admit liquid refrigerant into

the system in the discharge line. If adding refrigerant into

the suction line, use a commercial metering/expansion

device at the gauge manifold; remove liquid from the

cylinder, pass it through the metering device at the gauge

set and then pass it into the suction line as a vapor. Do not

remove Puron (R--410A) refrigerant from the cylinder as a

vapor.

Refrigerant Charge

Amount of refrigerant charge is listed on the unit’s

nameplate. Refer to Carrier GTAC2--5 Charging,

Recovery, Recycling and Reclamation training manual

and the following procedures.

Unit panels must be in place when unit is operating during

the charging procedure.

No Charge

Use standard evacuating techniques. After evacuating

system, weigh in the specified amount of refrigerant.

Low--Charge Cooling

Using Cooling Charging Charts, Fig. 12, vary refrigerant

until the conditions of the appropriate chart are met. Note

the charging charts are different from type normally used.

Charts are based on charging the units to the correct

superheat for the various operating conditions. Accurate

pressure gauge and temperature sensing device are

required. Connect the pressure gauge to the service port

on the suction line. Mount the temperature sensing device

on the suction line and insulate it so that outdoor ambient

temperature does not affect the reading. Indoor--air cfm

must be within the normal operating range of the unit.

To Use Cooling Charging Charts

Take the outdoor ambient temperature and read the

suction pressure gauge. Refer to chart to determine what

suction temperature should be. If suction temperature is

high, add refrigerant. If suction temperature is low,

carefully recover some of the charge. Recheck the suction

pressure as charge is adjusted.

1/2-20 UNF RH

30

0.596

.47

5/8” HEX

SEAT

CORE

WASHER

DEPRESSOR PER ARI 720

+.01/-.035

FROM FACE OF BODY

7/16-20 UNF RH

O-RING

45

torqued into the seat. Appropriate handling is

required to not scratch or dent the surface.

1/2" HEX

This surface provides a metal to metal seal when

o

o

(Part No. EC39EZ067)

C08453

Fig. 11 -- CoreMax Access Port Assembly

48TC