Orifice replacement – Carrier 48TCA04---A12 User Manual

Page 27

27

125,000/90,000 BTUH INPUT

180,000/120,000 BTUH INPUT

240,000/180,000 BTUH INPUT

250,000/200,000 BTUH INPUT

C08447

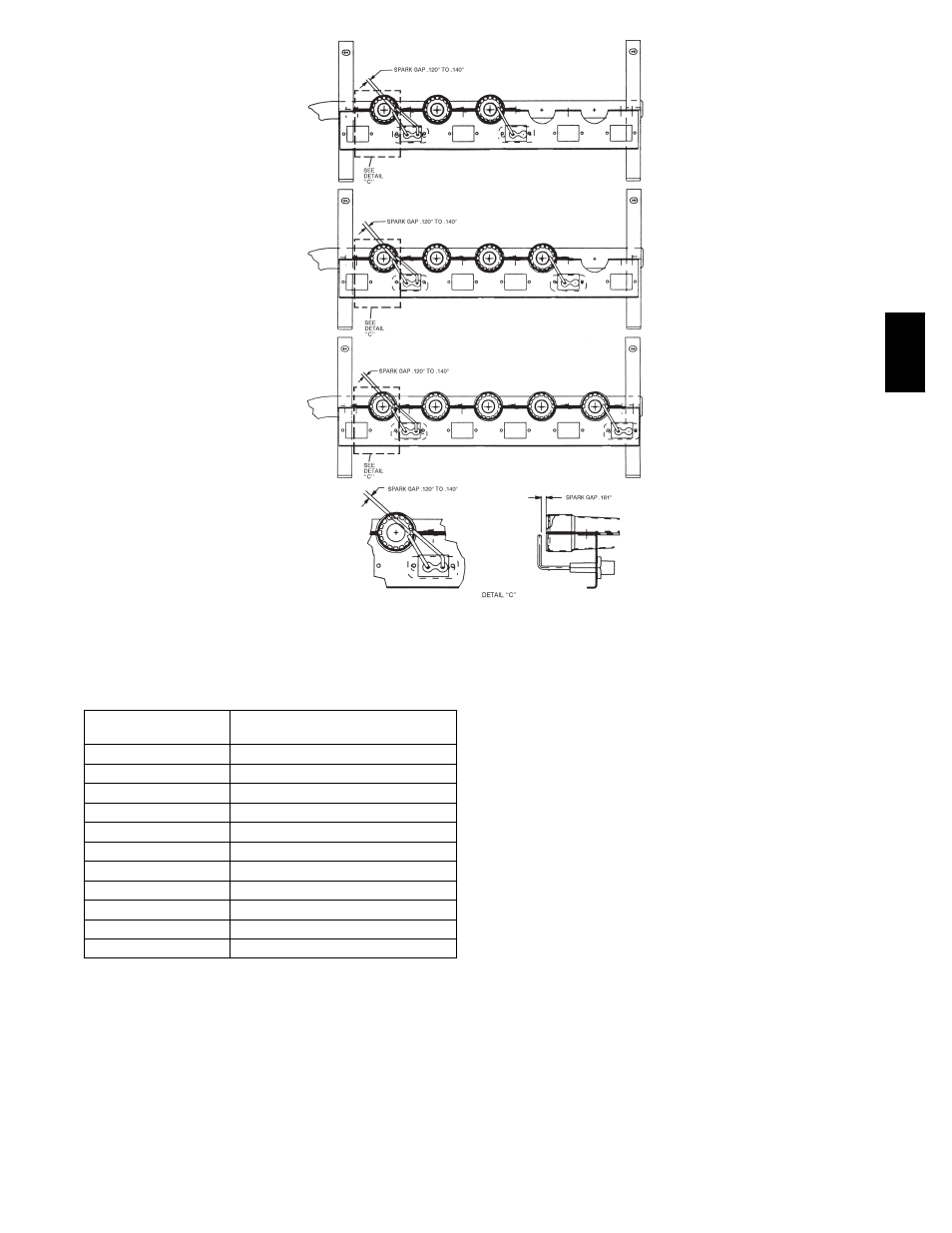

Fig. 36 -- Spark Adjustment (08--12)

Table 8 – LED Error Code Description*

LED INDICATION

ERROR CODE

DESCRIPTION

ON

Normal Operation

OFF

Hardware Failure

1 Flash{

Evaporator Fan On/Off Delay Modified

2 Flashes

Limit Switch Fault

3 Flashes

Flame Sense Fault

4 Flashes

4 Consecutive Limit Switch Faults

5 Flashes

Ignition Lockout Fault

6 Flashes

Induced---Draft Motor Fault

7 Flashes

Rollout Switch Fault

8 Flashes

Internal Control Fault

9 Flashes

Software Lockout

LEGEND

LED --- Light Emitting Diode

* A 3---second pause exists between LED error code flashes. If

.

more than one error code exists, all applicable codes will be

displayed in numerical sequence.

{

Indicates a code that is not an error. The unit will continue to

operate when this code is displayed.

IMPORTANT: Refer to Troubleshooting Table 13 and

Table 14 for additional information.

Orifice Replacement

This unit uses orifice type LH32RFnnn (where nnn

indicates orifice reference size). When replacing unit

orifices, order the necessary parts via Carrier RCD. See

Table 10 for available orifice sizes. See Table 11 and

Table 12 for orifice sizes for Natural Gas and LP fuel

usage at various elevations above sea level.

Check that each replacement orifice is tight at its threads

into the manifold pipe and that orifice projection does not

exceed maximum value. See Fig. 32.

48TC