Carrier 48TCA04---A12 User Manual

Page 62

62

graph with the left side of the chart to determine that the

range configuration for the CO

2

sensor should be 1800

ppm. The EconoMi$er IV controller will output the 6.7

volts from the CO

2

sensor to the actuator when the CO

2

concentration in the space is at 1100 ppm. The DCV

setpoint may be left at 2 volts since the CO

2

sensor

voltage will be ignored by the EconoMi$er IV controller

until it rises above the 3.6 volt setting of the minimum

position potentiometer.

Once the fully occupied damper position has been

determined, set the maximum damper demand control

ventilation potentiometer to this position. Do not set to the

maximum position as this can result in over-ventilation to

the space and potential high humidity levels.

CO

2

Sensor Configuration

The CO

2

sensor has preset standard voltage settings that

can be selected anytime after the sensor is powered up.

(See Table 28.)

Use setting 1 or 2 for Carrier equipment. (See Table 28.)

1. Press Clear and Mode buttons. Hold at least 5

seconds until the sensor enters the Edit mode.

2. Press Mode twice. The STDSET Menu will appear.

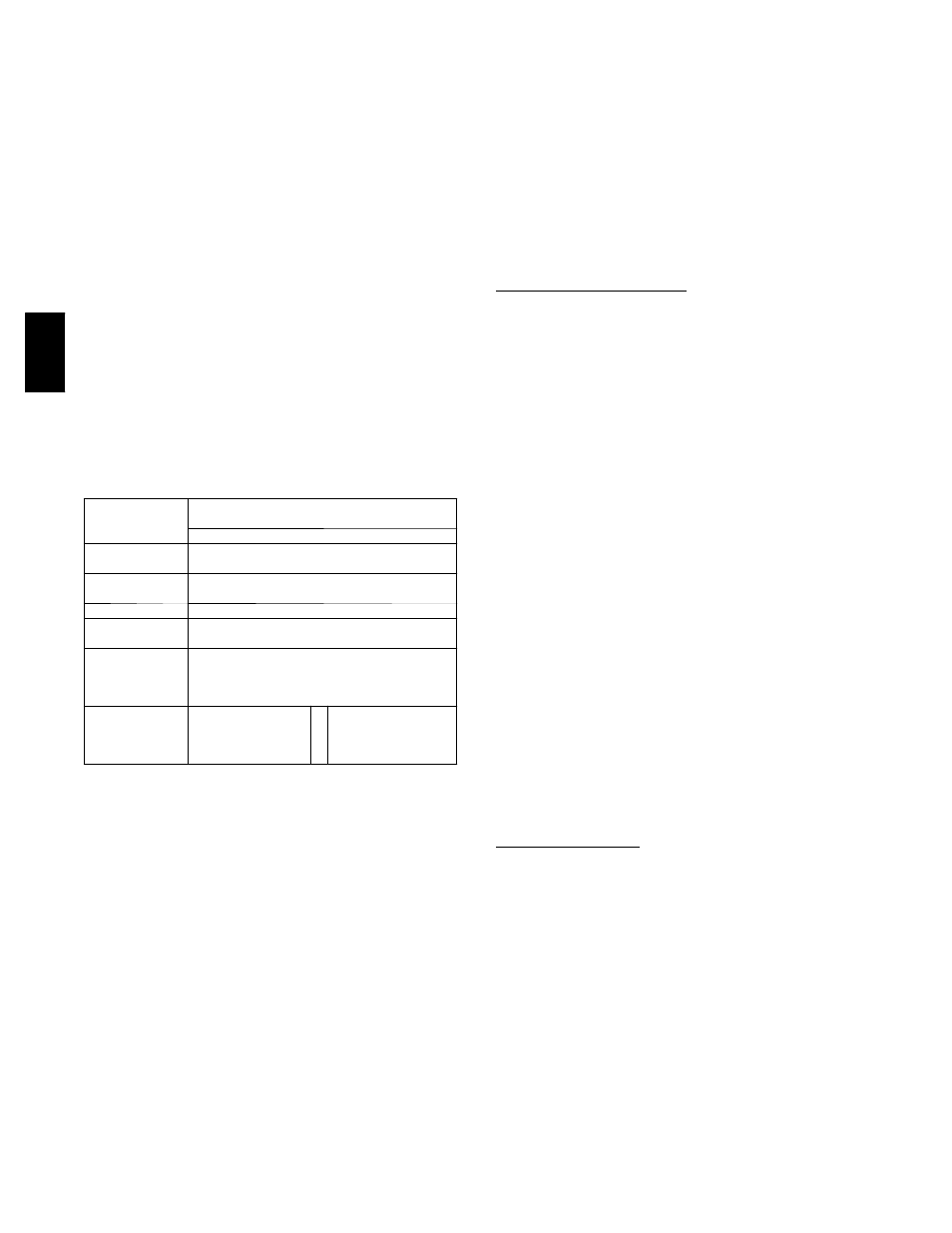

Table 28 – EconoMi$er IV Sensor Usage

APPLICATION

ECONOMI$ER IV WITH OUTDOOR AIR DRY

BULB SENSOR

Accessories Required

Outdoor Air

Dry Bulb

None. The outdoor air dry bulb sensor is

factory installed.

Differential

Dry Bulb

CRTEMPSN002A00*

Single Enthalpy

HH57AC078

Differential

Enthalpy

HH57AC078 and CRENTDIF004A00*

CO

2

for DCV

Control using a

Wall-Mounted

CO

2

Sensor

33ZCSENCO2

CO

2

for DCV

Control using a

Duct-Mounted

CO

2

Sensor

33ZCSENCO2† and

33ZCASPCO2**

O

R CRCBDIOX005A00††

* CRENTDIF004A00 and CRTEMPSN002A00 accessories are

used on many different base units. As such, these kits may

contain parts that will not be needed for installation.

† 33ZCSENCO2 is an accessory CO

2

sensor.

** 33ZCASPCO2 is an accessory aspirator box required for duct-

mounted applications.

†† CRCBDIOX005A00 is an accessory that contains both

33ZCSENCO2 and 33ZCASPCO2 accessories.

3. Use the Up/Down button to select the preset

number. (See Table 28.)

4. Press Enter to lock in the selection.

5. Press Mode to exit and resume normal operation.

The custom settings of the CO

2

sensor can be changed

anytime after the sensor is energized. Follow the steps

below to change the non-standard settings:

1. Press Clear and Mode buttons. Hold at least 5

seconds until the sensor enters the Edit mode.

2. Press Mode twice. The STDSET Menu will appear.

3. Use the Up/Down button to toggle to the NONSTD

menu and press Enter.

4. Use the Up/Down button to toggle through each of

the nine variables, starting with Altitude, until the

desired setting is reached.

5. Press Mode to move through the variables.

6. Press Enter to lock in the selection, then press Mode

to continue to the next variable.

Dehumidification of Fresh Air with DCV (Demand

Controlled Ventilation) Control

If normal rooftop heating and cooling operation is not

adequate for the outdoor humidity level, an energy

recovery unit and/or a dehumidification option should be

considered.

EconoMi$er IV Preparation

This procedure is used to prepare the EconoMi$er IV for

troubleshooting. No troubleshooting or testing is done by

performing the following procedure.

NOTE:

This procedure requires a 9--v battery, 1.2

kilo--ohm resistor, and a 5.6 kilo--ohm resistor which are

not supplied with the EconoMi$er IV.

IMPORTANT: Be sure to record the positions of all

potentiometers before starting troubleshooting.

1. Disconnect power at TR and TR1. All LEDs should

be off. Exhaust fan contacts should be open.

2. Disconnect device at P and P1.

3. Jumper P to P1.

4. Disconnect wires at T and T1. Place 5.6 kilo--ohm

resistor across T and T1.

5. Jumper TR to 1.

6. Jumper TR to N.

7. If connected, remove sensor from terminals SO and +.

Connect 1.2 kilo--ohm 4074EJM checkout resistor

across terminals SO and +.

8. Put 620--ohm resistor across terminals SR and +.

9. Set minimum position, DCV setpoint, and exhaust po-

tentiometers fully CCW (counterclockwise).

10. Set DCV maximum position potentiometer fully CW

(clockwise).

11. Set enthalpy potentiometer to D.

12. Apply power (24 vac) to terminals TR and TR1.

Differential Enthalpy

To check differential enthalpy:

1. Make sure EconoMi$er IV preparation procedure has

been performed.

2. Place 620--ohm resistor across SO and +.

3. Place 1.2 kilo--ohm resistor across SR and +. The

Free Cool LED should be lit.

4. Remove 620--ohm resistor across SO and +. The Free

Cool LED should turn off.

5. Return EconoMi$er IV settings and wiring to normal

after completing troubleshooting.

48TC