Caution – Carrier 48TCA04---A12 User Manual

Page 25

25

Burners and Igniters

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in

equipment damage.

When working on gas train, do not hit or plug

orifice spuds.

CAUTION

!

Main Burners

To access burners, remove burner access panel and slide

out burner partition. At the beginning of each heating

season, inspect for deterioration or blockage due to

corrosion or other causes. Observe the main burner flames

and adjust, if necessary.

Orifice projection — Refer to Fig. 32 for maximum

projection dimension for orifice face to manifold tube.

Orifice

1.00-in

(25.4 mm)

Manifold

Pipe

C08211

Fig. 32 -- Orifice Projection

Removal and Replacement of Gas Train

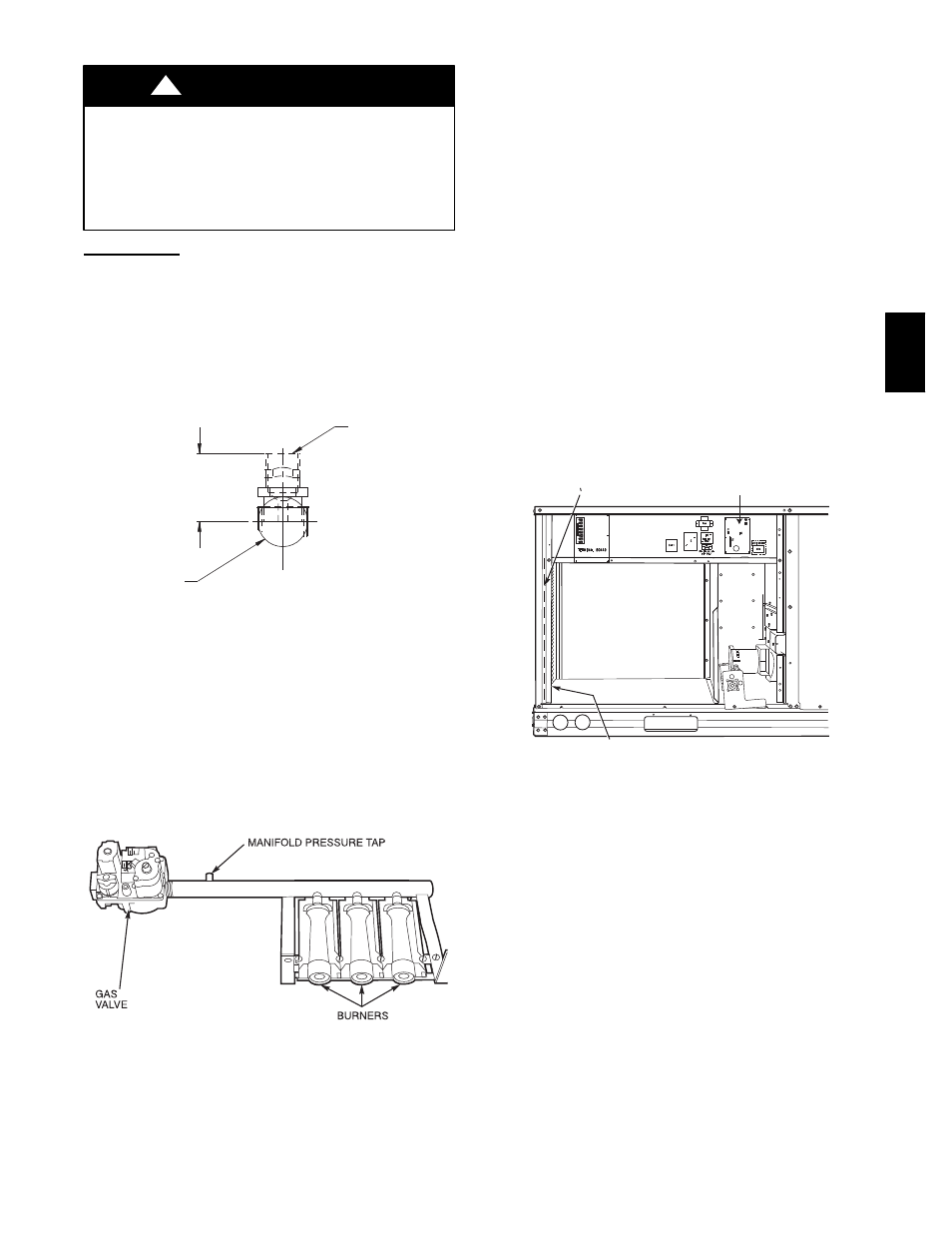

See Fig. 27, Fig. 31 and Fig. 33.

1. Shut off manual gas valve.

2. Shut off power to unit.

3. Slide out burner partition.

4. Disconnect gas piping at unit gas valve.

5. Remove wires connected to gas valve. Mark each

wire.

C06153

Fig. 33 -- Burner Tray Details

6. Remove igniter wires and sensor wires at the Integ-

rated Gas Unit Controller (IGC). (See Fig. 34.)

7. Remove the 2 screws that attach the burner rack to

the vestibule plate (Fig. 31).

8. Slide the burner tray out of the unit (Fig. 33).

9. To reinstall, reverse the procedure outlined above.

Cleaning and Adjustment

1. Remove burner rack from unit as described in Re-

moval and Replacement of Gas Train section, above.

2. Inspect burners; if dirty, remove burners from rack.

(Mark each burner to identify its position before re-

moving from the rack.)

3. Use a soft brush to clean burners and cross--over port

as required.

4. Adjust spark gap. (See Fig. 35 and Fig. 36.)

5. If factory orifice has been removed, check that each

orifice is tight at its threads into the manifold pipe

and that orifice projection does not exceed maximum

valve. See Fig. 32

6. Reinstall burners on rack in the same locations as

factory--installed. (The outside crossover flame re-

gions of the outermost burners are pinched off to pre-

vent excessive gas flow from the side of the burner

assembly. If the pinched crossovers are installed

between two burners, the flame will not ignite prop-

erly.)

RACEWAY

INTEGRATED GAS UNIT

CONTROLLER (IGC)

HOLE IN END PANEL (HIDDEN)

C08454

Fig. 34 -- Unit Control Box/IGC Location

7. Reinstall burner rack as described in Removal and

Replacement of Gas Train section, above.

Gas Valve — All three--phase models (except Low NO

x

)

are equipped with 2--stage gas valves. Single--phase

models and all Low NO

x

models are equipped with

single--stage gas valves. See Fig. 37 for locations of

adjustment screws and features on the gas valves.

To adjust gas valve pressure settings:

IMPORTANT: Leak check all gas connections including

the main service connection, gas valve, gas spuds, and

manifold pipe plug. All leaks must be repaired before

firing unit.

Check Unit Operation and Make Necessary Adjust-

ments

NOTE: Gas supply pressure at gas valve inlet must be

within specified ranges for fuel type and unit size. See

Table 4 and Table 5.

48TC