Caution, Detector cleaning, Indicators – Carrier 48TCA04---A12 User Manual

Page 20

20

SD--TRK4 Remote Alarm Test Procedure

1. Turn the key switch to the RESET/TEST position for

seven seconds.

2. Verify that the test/reset station’s Alarm LED turns

on.

3. Reset the sensor by turning the key switch to the

RESET/TEST position for two seconds.

4. Verify that the test/reset station’s Alarm LED turns

off.

Remote Test/Reset Station Dirty Sensor Test

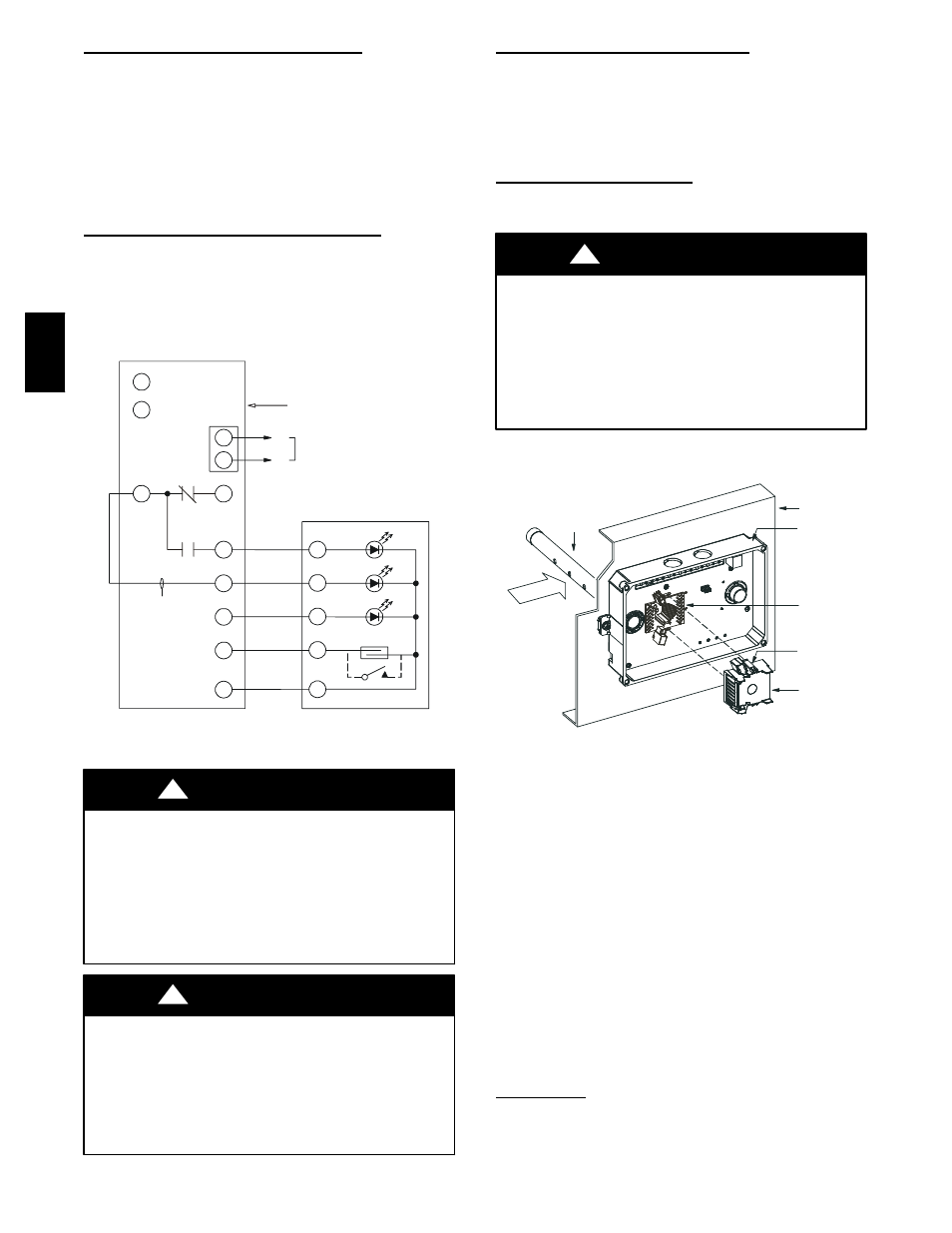

The test/reset station dirty sensor test checks the test/reset

station’s ability to initiate a sensor dirty test and indicate

the results. It must be wired to the controller as shown in

Fig. 24 and configured to operate the controller’s

supervision relay. For more information, see “Changing

sensor dirty test operation.”

1

12

14

13

19

15

2

20

3

Reset/Test

Trouble

Power

Alarm

Supervision relay

contacts [3]

5

4

1

3

2

SD-TRK4

2

1

TB3

18 Vdc ( )

+

18 Vdc ( )

−

Auxiliary

equipment

+

−

Wire must be

added by installer

Smoke Detector Controller

C08247

Fig. 24 -- Remote Test/Reset Station Connections

OPERATIONAL TEST HAZARD

Failure to follow this caution may result in personnel

and authority concern.

If the test/reset station’s key switch is left in the

RESET/TEST position for longer than seven seconds,

the detector will automatically go into the alarm state

and activate all automatic alarm responses.

CAUTION

!

OPERATIONAL TEST HAZARD

Failure to follow this caution may result in personnel

and authority concern.

Holding the test magnet to the target area for longer

than seven seconds will put the detector into the alarm

state and activate all automatic alarm responses.

CAUTION

!

Dirty Sensor Test Using an SD--TRK4

1. Turn the key switch to the RESET/TEST position for

two seconds.

2. Verify that the test/reset station’s Trouble LED

flashes.

Detector Cleaning

Cleaning the Smoke Detector

Clean the duct smoke sensor when the Dirty LED is

flashing continuously or sooner if conditions warrant.

OPERATIONAL TEST HAZARD

Failure to follow this caution may result in personnel

and authority concern.

If the smoke detector is connected to a fire alarm

system, first notify the proper authorities that the

detector is undergoing maintenance then disable the

relevant circuit to avoid generating a false alarm.

CAUTION

!

1. Disconnect power from the duct detector then remove

the sensor’s cover. (See Fig. 25.)

Airflow

HVAC duct

Sampling

tube

Retainer

clip

Optic

plate

Optic

housing

Sensor

housing

C07305

Fig. 25 -- Sensor Cleaning Diagram

2. Using a vacuum cleaner, clean compressed air, or a

soft bristle brush, remove loose dirt and debris from

inside the sensor housing and cover.

Use isopropyl alcohol and a lint--free cloth to remove

dirt and other contaminants from the gasket on the

sensor’s cover.

3. Squeeze the retainer clips on both sides of the optic

housing then lift the housing away from the printed

circuit board.

4. Gently remove dirt and debris from around the optic

plate and inside the optic housing.

5. Replace the optic housing and sensor cover.

6. Connect power to the duct detector then perform a

sensor alarm test.

INDICATORS

Normal State

The smoke detector operates in the normal state in the

absence of any trouble conditions and when its sensing

chamber is free of smoke. In the normal state, the Power

48TC