Caution – Reznor R6GN Option - Installation - High Static Blower Drive - Light Commercial User Manual

Page 7

7

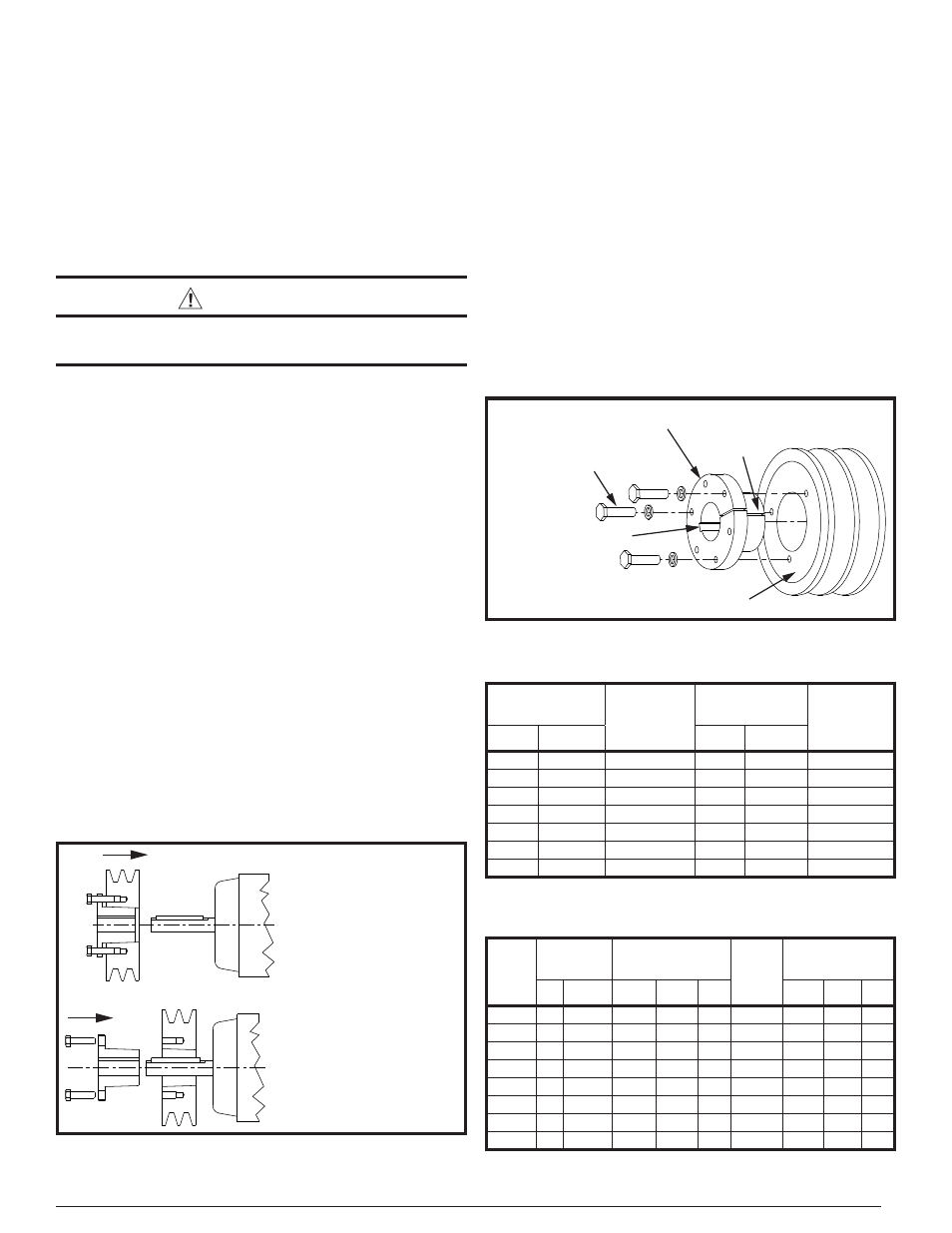

Mounting Split Taper Bushings in Split Taper Bushed

Pulleys

Pre- Installation

• Make sure the shaft, bushing barrel & bore, split taper pulley

bore, keys and keyways are free of burrs, paint, etc.

• The bushing may fi rst be loosely installed into the split taper

bored pulley, and then the assembly slid onto the shaft.

For heavier pulley’s, it may be easier to either fi rst slide the

bushing onto the shaft and then slide the pulley onto the

bushing; however, if the bushing barrel has collapsed, it

must be wedged open. See Figure 4.

CAUTION:

Excessive wedging forces in bushing saw slot may

damage or break bushing.

• It may be necessary to slightly wedge open the saw slot

(Figure 5) on some bushings in order to start the bore and

position the bushing onto the shaft. A narrow edged regular

screw driver may be used.

Pulley Installation

1. Align the keyway in the bushing bore with the shaft keyway

and install the key. Make sure the key runs the entire length

of the bushing bore. See Figure 5.

2. Position the pulley so the keyway in the bore is aligned with

the external (barrel) key in the bushing. NOTE: Bushings do

not have an external key. The threaded holes in the pulley

must be aligned with the non-threaded holes in the bushing

fl ange. Insert the cap screws through the non-threaded

holes in the bushing fl ange and thread them by hand into

the pulley three or four turns.

3. Position the bushing & pulley assembly axially on the shaft

such that it is aligned with its running mate. NOTE: Check

for adequate clearance between the assembly and other

nearby components (if applicable). Various shaft sizes are

listed in Table 5.

4. Install cap screws and tighten by hand fi rst. NOTE: If cap

screws were provided with the pulley, use them instead of

the ones provided with the bushing. Since tightening the cap

screws may affect the axial position of the pulley, confi rm

Split Taper Bushing

Split Taper Pulley

Cap Screws & Washers (3)

Keyway

Saw Slot

Figure 5. Split Taper Bushing & Pulley Assembly

Split Taper Pulley & Bushing

Components Assembled and

then Installed on Shaft

Split Taper Pulley & Bushing

Components Installed on

Shaft Individually

Figure 4. Split Taper Bushing & Pulley Assembly

Options

that the pulley is properly aligned with its running mate. If

not, determine how much the assembly must be moved into

proper alignment. Split taper tightening torques are listed

in Table 6.

5. If axial adjustment is required, fi rst attempt to move the

motor sheave to properly align the drive belt.

6. Check installation gap. NOTE: There must be a gap between

the bushing fl ange and the pulley face. If there is no gap

between them, disassemble the parts and determine the

reason(s) for the faulty assembly.

Pulley Removal

1. Remove all cap screws in sequence. If the bushing has a

keyway set screw, loosen it.

2. Insert cap screws in all threaded bushing fl ange holes.

Tighten the cap screws against the (hub) face of the pulley

until the screw force releases the pulley from the bushing.

3. Remove the bushing and pulley from the shaft.

SHAFT SIZE

RANGE (IN)

LOWER

SHAFT

SIZE LIMIT

(IN)

SHAFT SIZE

RANGE (IN)

LOWER

SHAFT

SIZE LIMIT

(MM)

Above

Through

Above

Through

–

1 1/2

-0.003

—

38.1

-0.076

1 1/2

2 1/2

-0.004

38.1

63.5

-0.102

2 1/2

4

-0.005

63.5

101.6

-0.127

4

6

-0.006

101.6

152.4

-0.152

6

8

-0.007

152.4

203.2

-0.178

8

9

-0.008

203.2

228.6

-0.203

9

—

-0.009

228.6

—

-0.229

Table 5. Shaft Size Limits for Split Taper Bushings

Bushing

SAE Grade 5

Cap Screw

Cap Screw Torque

Set

Screw

Size

Set Screw Torque

No.

Size

(in-Lbs) (Ft-Lbs) (N-M)

(in-Lbs) (Ft-Lbs) (N-M)

G;H

2

1/4-20NC

95

8

10.7

-

-

-

-

P;B

3

5/16-18NC

192

16

21.7

-

-

-

-

Q

3

3/8-16NC

348

29

39.3

5/16-18NC

165*

13.8* 18.6*

R

3

3/8-16NC

348

29

39.3

5/16-18NC

165

13.8

18.6

S

3

3/8-16NC

840

140

189.8

3/8-16NC

290

24.2

32.8

U

3

5/8-11NC

1680

140

189.8

3/8-16NC

290

24.2

32.8

W

4

3/4-10NC

3000

250

339.0

1/2-13NC*

620*

51.7* 70.1*

YO

4

1-8NC

7200

600

813.5

1/2-13NC*

620*

51.7* 70.1*

Table 6. Split Taper Tightening Torques