Great Planes Piper J-3 Cub 20 Kit - GPMA0158 User Manual

Page 7

Inches x 25.4 = mm (conversion factor)

1 /64" = .4mm 3/4" = 19.0mm

1/32" = .8mm 1" = 25.4mm

1/16"= 1.6mm 2" = 50.8mm

3/32" = 2.4mm 3" = 76.2mm

1/8" = 3.2mm 6" = 152.4mm

5/32" = 4.0mm 12" = 304.8mm

3/16" = 4.8mm 18" = 457.2mm

1/4"= 6.4mm 21"= 533.4mm

3/8" = 9.5mm 24" = 609.6mm

1/2" = 12.7mm 30" = 762.0mm

5/8" = 15.9mm 36" = 914.4mm

D 1. Unroll the plan sheets. Reroll the plans inside out to

make them lie flat.

D 2. Remove all parts from the box. As you do, determine

the name of each part by comparing it with the plans and

the parts list included in this kit. Using a felt tip pen or ball

point pen, write the part name or size on each piece to

avoid confusion later. Use the die-cut patterns shown on

page 6 to identify the die-cut parts and mark them before

removing them from the sheet. Save all scraps. If any of the

die-cut parts are difficult to punch out, do not force them!

Instead, cut around the parts with a hobby knife.

After punching out the die-cut parts, use your T-Bar or

sanding block to lightly sand the edges to remove any

die-cutting irregularities.

D 3. As you identify and mark the parts, separate them into

groups, such as fuse (fuselage), wing, fin and stab

(stabilizer) and hardware.

IMPORTANT: For a model that flies well with no

unexpected tendencies, all good modelers understand that

each assembly, especially the wing, must be built on a flat

surface. Also, a relatively soft, flat building board that you

can stick "T" pins into is required. This is for pinning down

individual parts during construction. A suitable building

board is a sheet of "Celotex" used in home construction.

This material may be found at hardware or home

improvement stores. If the building board is not flat, it must

be clamped to your flat building table. Now we're ready

to begin!

Okay, you've got your work space ready, your tools are

at hand and you know how to choose and use the right

glue for the job. Let's get started!

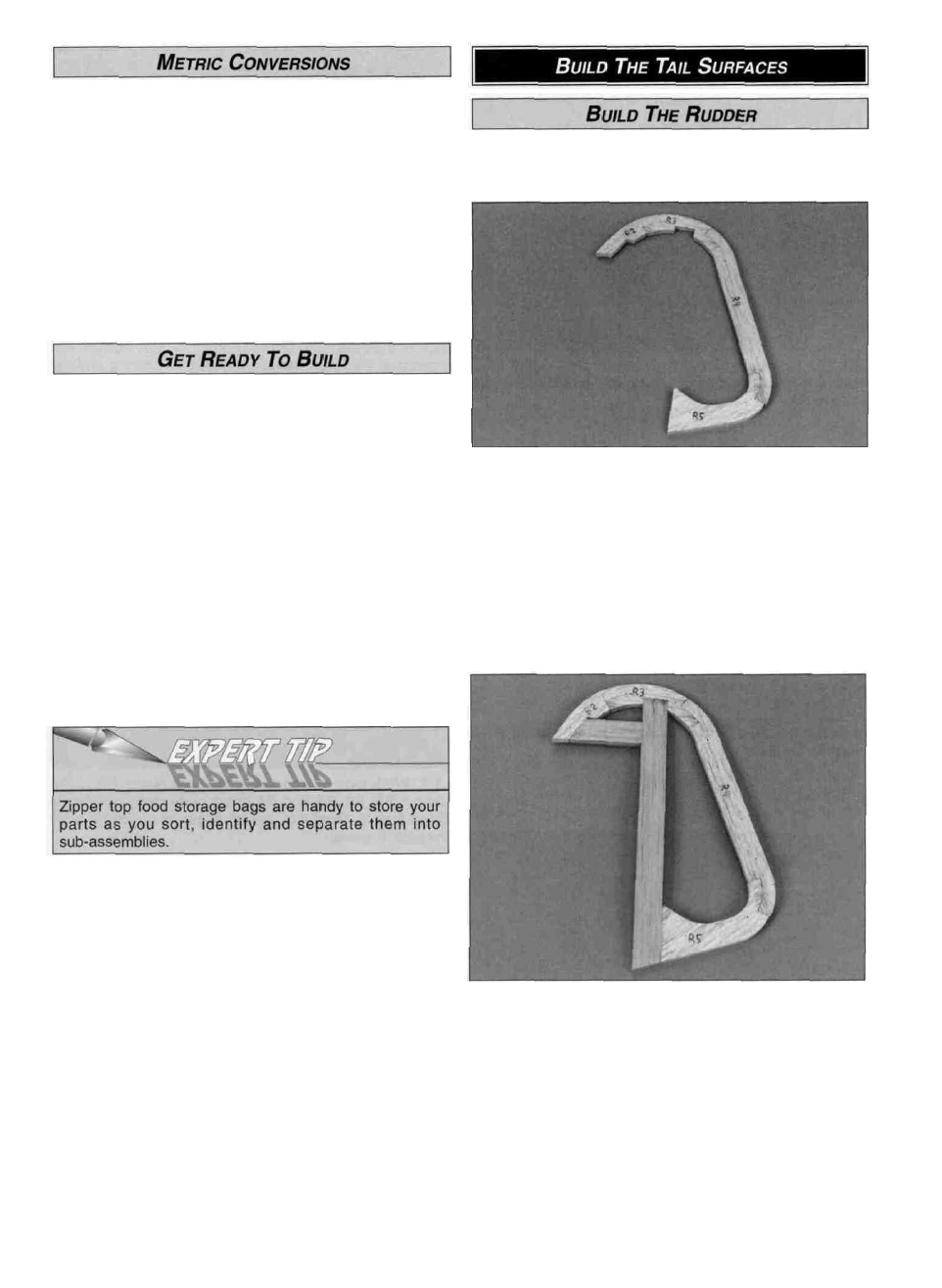

Tape the plan to a flat building surface, then cover the fin

and rudder section with waxed paper. Refer to the plan to

identify the parts and their locations.

D 1. Place the die-cut 3/16" balsa rudder parts R2, R3, R4

and R5 over the plan in their locations. Check their fit and

sand the mating edges as needed. Use a T-bar or other flat

sanding block to make any necessary adjustments. Pin the

parts to the building board after proper alignment and fitting

has been done. Do not glue the parts together at this time.

D 2. Select the straightest piece from the four

3/16" x 5/8" x 18" balsa sticks. Set this piece aside for use

later on the stabilizer trailing edge.

D 3. Cut the rudder LE from another 3/16" x 5/8" x 18"

balsa stick. Fit the LE into the notch in R3 and against the

edge of R5. Cut the horizontal frame section from the

3/16" x 5/8" x 18" left over from the rudder leading edge,

and fit it in position. Pin the LE and horizontal frame section

in place and glue all the parts together with thin CA. Wipe

off any excess glue from the surface before it cures.

NOTE: Leave all the parts pinned to the building board.

7